PECVD film plating machine

A coating machine and silicon wafer technology, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of high single-sidedness of the film, deformation of silicon wafers, winding plating, etc., and achieve a favorable level Stability, increase coating output, improve the effect of coating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings. It should be noted that specific embodiments are only detailed elaborations of the present invention, and its purpose is to enable those skilled in the art to better understand and implement the present invention. regarded as a limitation of the present invention.

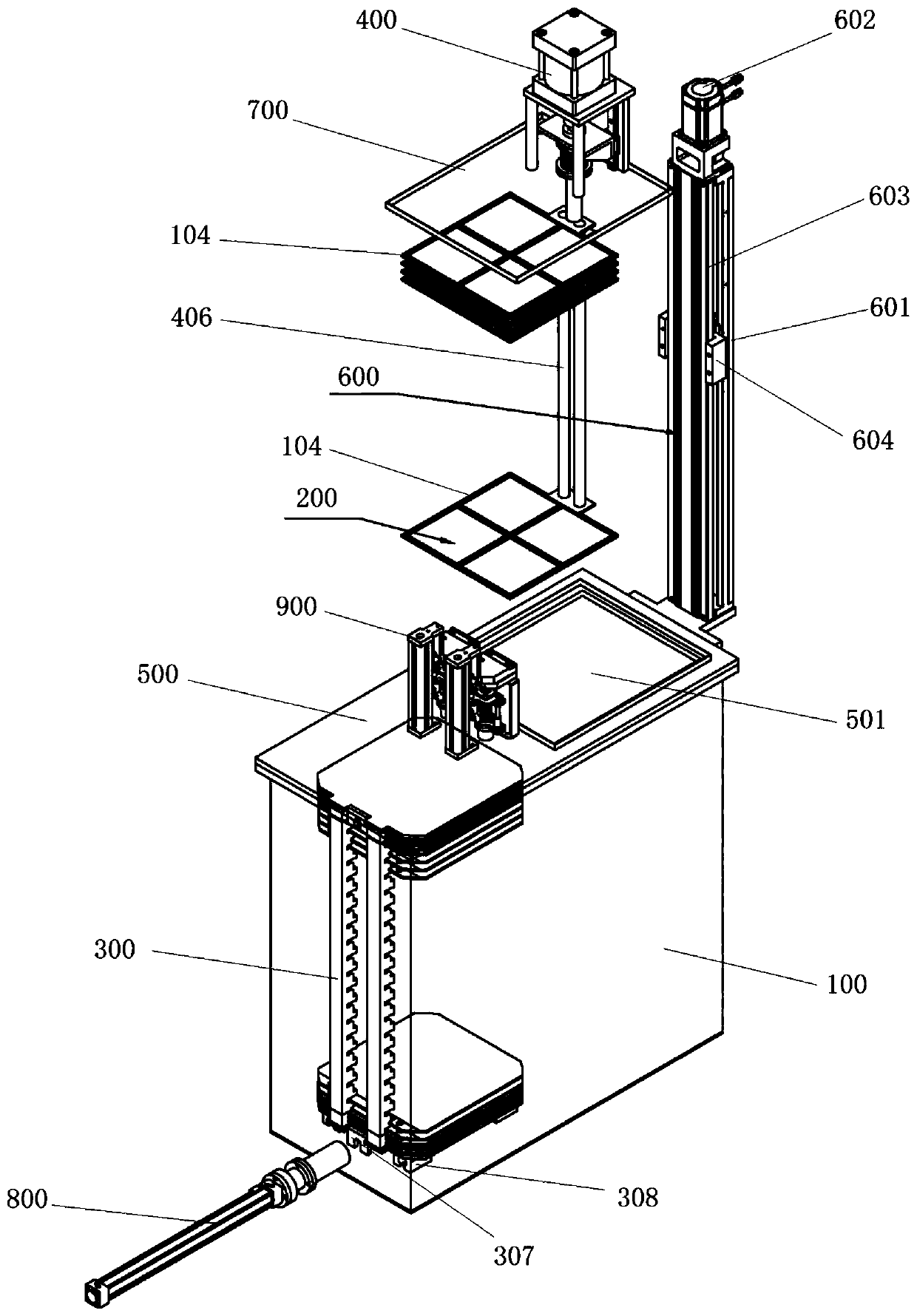

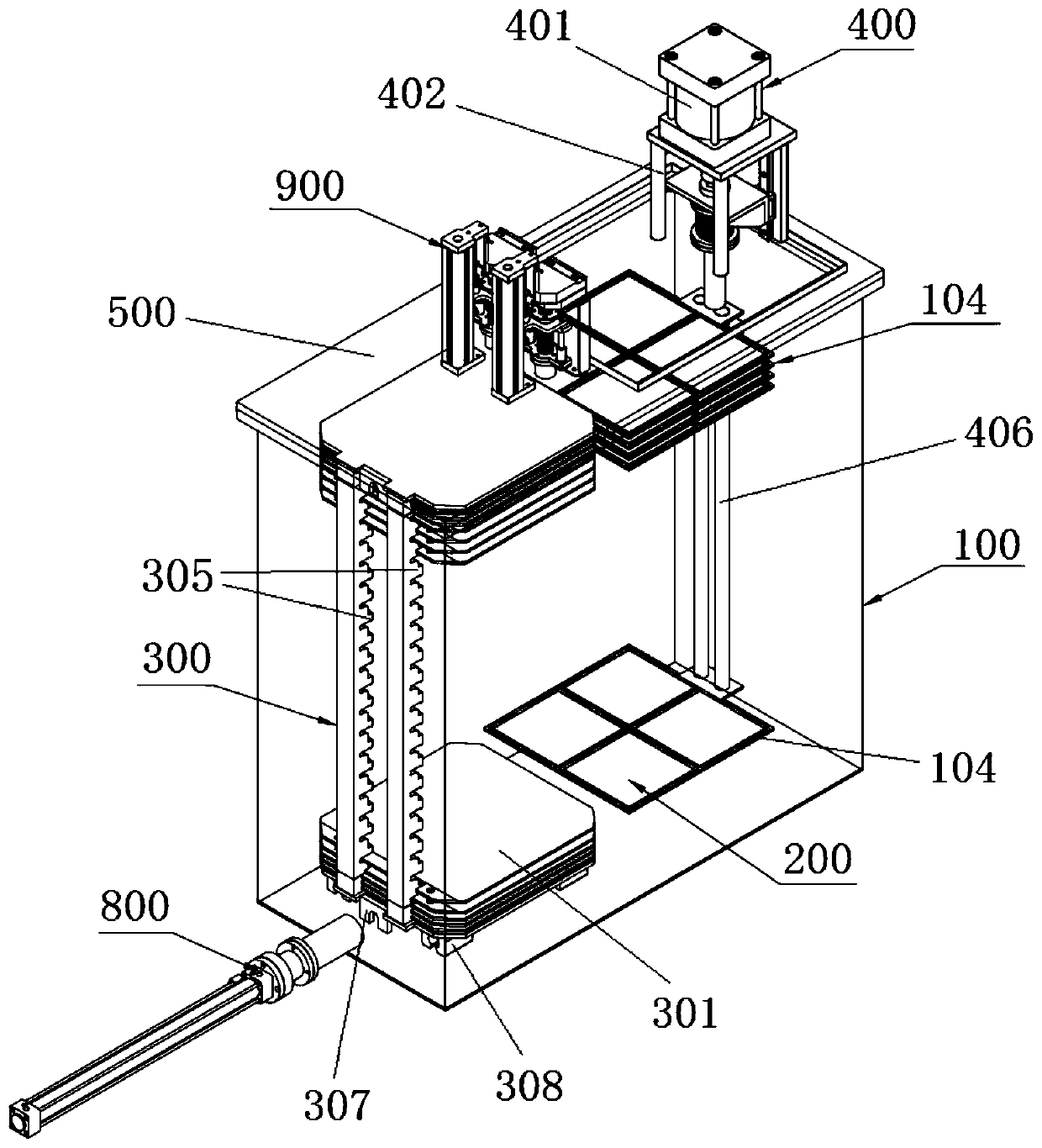

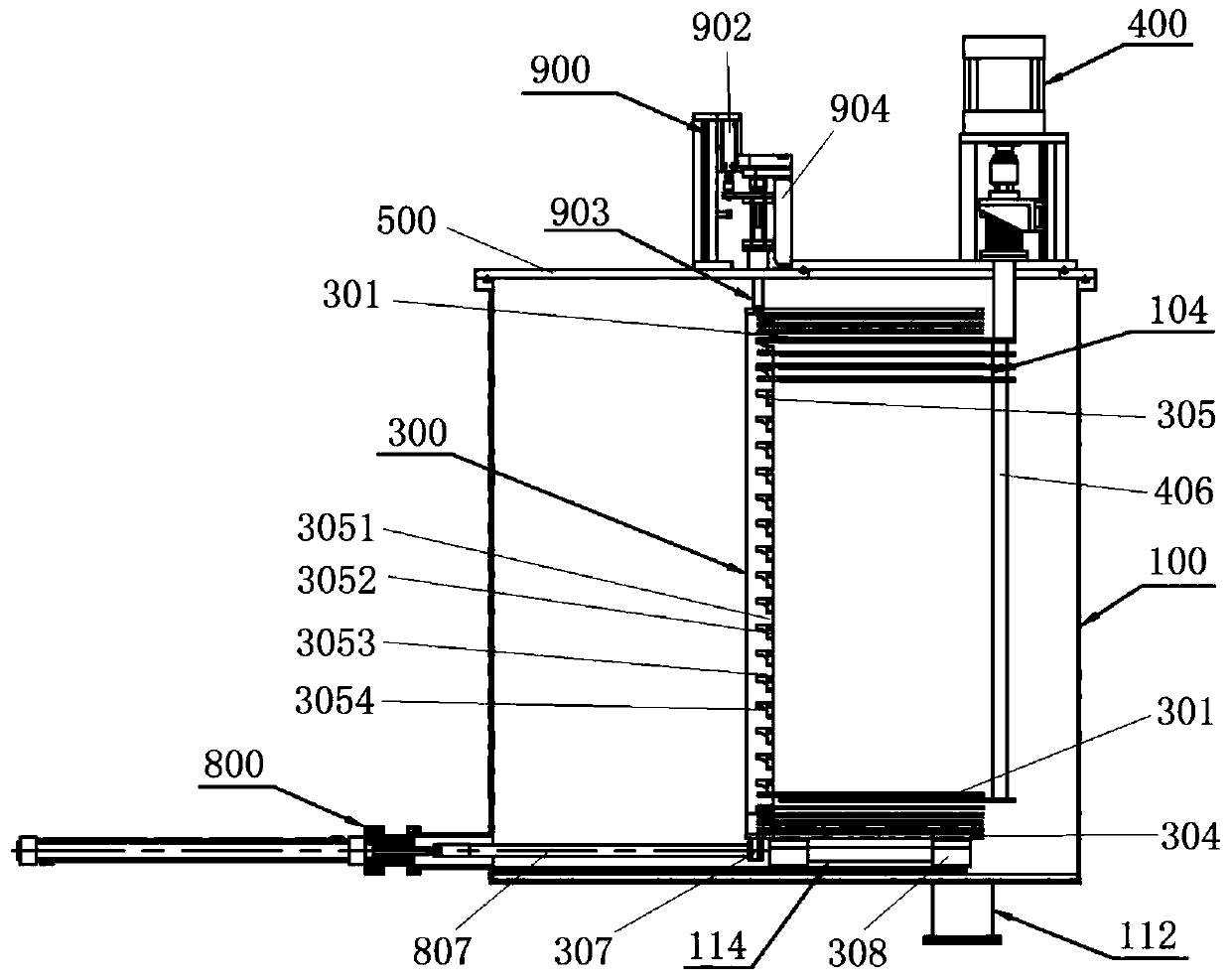

[0029] Such as Figure 1-3 As shown, the present invention provides a PECVD film coating machine, including a vacuum furnace chamber 100 for coating operations, said vacuum furnace chamber 100 is provided with at least two work stations related to silicon wafers, one of which is the pre-processing of silicon wafers. Loading station 101, the other is the firing station 102 of the silicon wafer, above the firing station 102 of the silicon wafer is the loading station 103 of the silicon wafer, on the loading station 103 of the silicon wafer, the silicon wafer 200 is passed The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com