Method and device for controlling a camshaft phase adjuster in an internal combustion engine

一种相位调节器、凸轮轴的技术,应用在阀装置、电气控制、发动机控制等方向,能够解决过调控制偏差、系统控制质量偏差等问题,达到减少应用耗费、改进控制质量的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

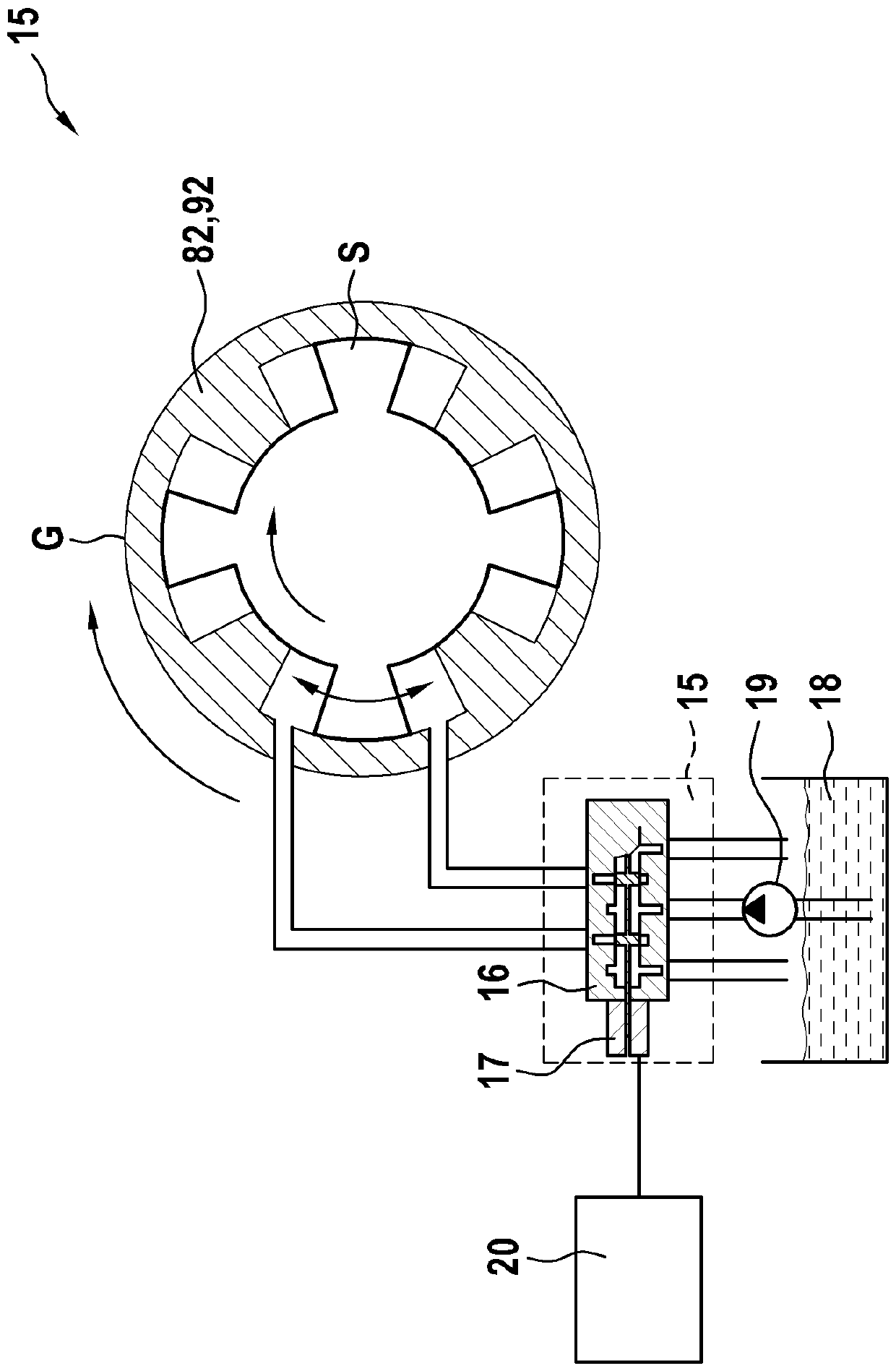

[0039] figure 1 A schematic diagram of a motor system 1 with a combustion motor 2 is shown, which can be constructed in the form of a reciprocating piston combustion motor. The combustion motor 2 can correspond to an air-guided combustion motor (gasoline motor) or a fuel-guided combustion motor (diesel motor). Combustion motor 2 has pistons 3 which are movable in translation within combustion chambers of cylinders 3 and which are coupled via a connecting rod 4 to a crankshaft 5 in a manner known per se.

[0040]Cylinders 3 of combustion motor 2 operate in four-stroke operation, air being circulated into cylinders 3 via intake valve 6 and combustion exhaust gases exiting cylinders 3 via exhaust valve 7 . The valve operation of the intake and exhaust valves 6 , 7 is controlled via the corresponding camshafts, namely the intake camshaft 8 and the exhaust camshaft 9 . The camshafts 8 , 9 are mechanically connected phase-synchronously to the crankshaft 5 , for example via a tooth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com