Supporting truss rod and space truss structure

A technology for supporting trusses and space trusses, applied in the field of space optical remote sensing, can solve the problems of large stress at the bonding position and poor reliability of the bonding process, and achieve the effect of large connection surface, simple and reliable screw connection, and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The core idea of the present invention is to adopt a low-stress pre-embedding method to reduce the assembly stress and thermal stress that may be generated when the truss rod is bonded to the metal parts, and to improve the connection strength and reliability. At the same time, the integrated support truss rod assembly can simplify the assembly process of the truss structure.

[0037] Below in conjunction with accompanying drawing and specific embodiment carry out further detailed description:

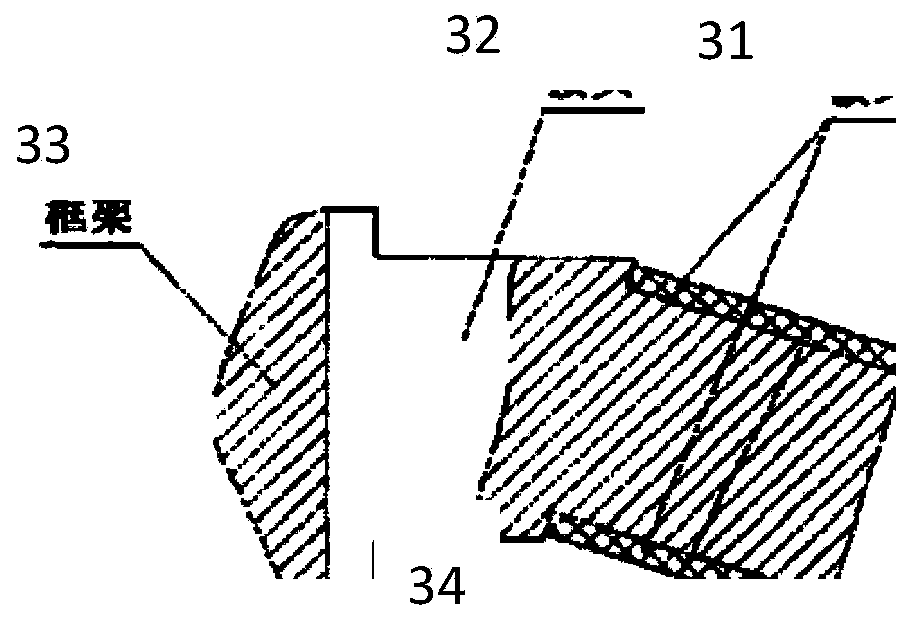

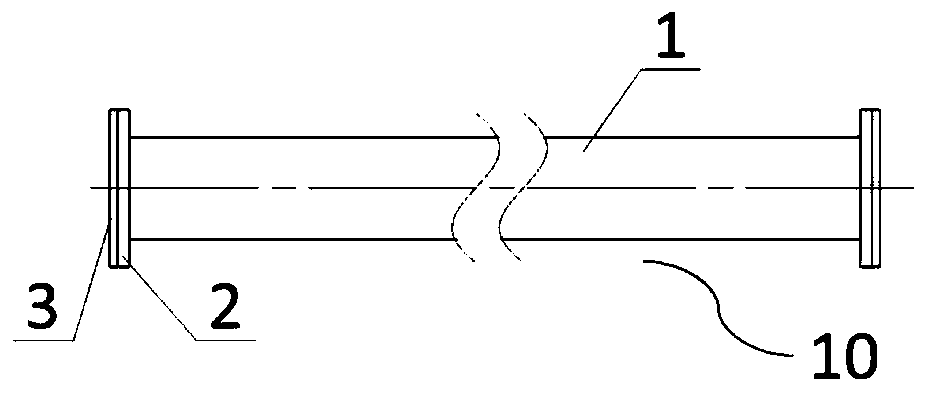

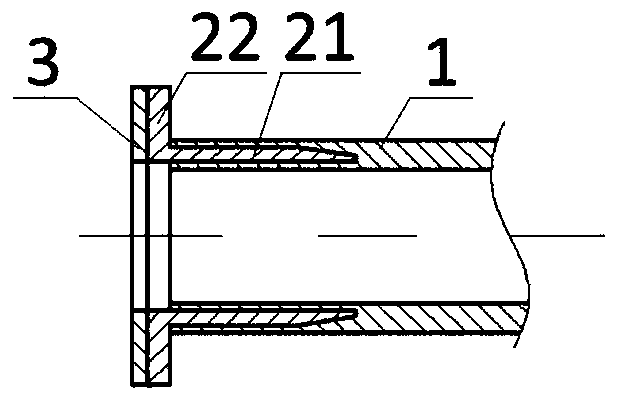

[0038] figure 2 and image 3 They are the front view and end cross-sectional view of the supporting truss bar respectively. The assembly includes the truss bar body 1 and the connection assembly arranged at both ends of the truss bar body 1 , wherein the connection assembly includes the embedded part 2 and the metal bottom plate 3 . The truss rod body 1 is a hollow rod wound with M40 carbon fiber material. The embedded part 2 is made of carbon fiber reinforced SiC ceramic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com