Polyurethane elastic fiber with ultrasonic bonding performance and preparation method thereof

A polyurethane elasticity and adhesion performance technology, applied in the direction of fiber chemical characteristics, single-component synthetic polymer rayon, rayon manufacturing, etc., can solve the influence of spinning and material properties, low welding energy utilization rate, low welding strength and other problems, to achieve the effect of good spinning stability, improved physical properties, and avoidance of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

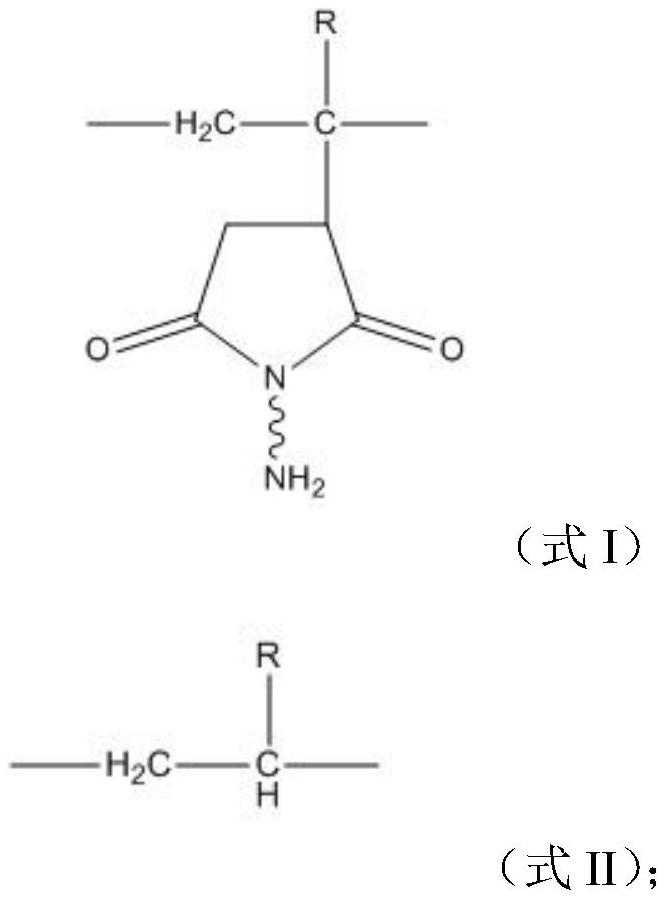

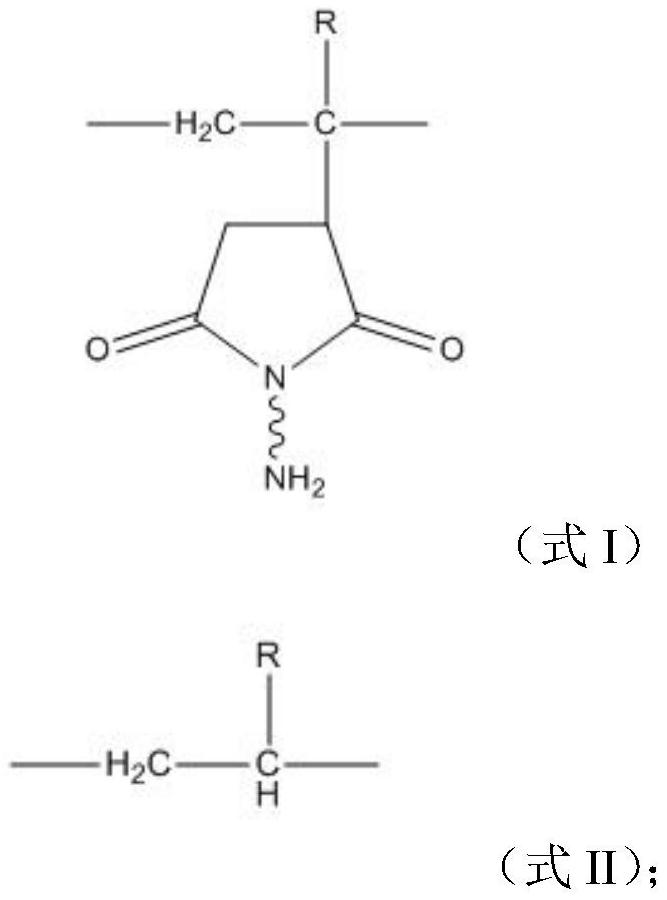

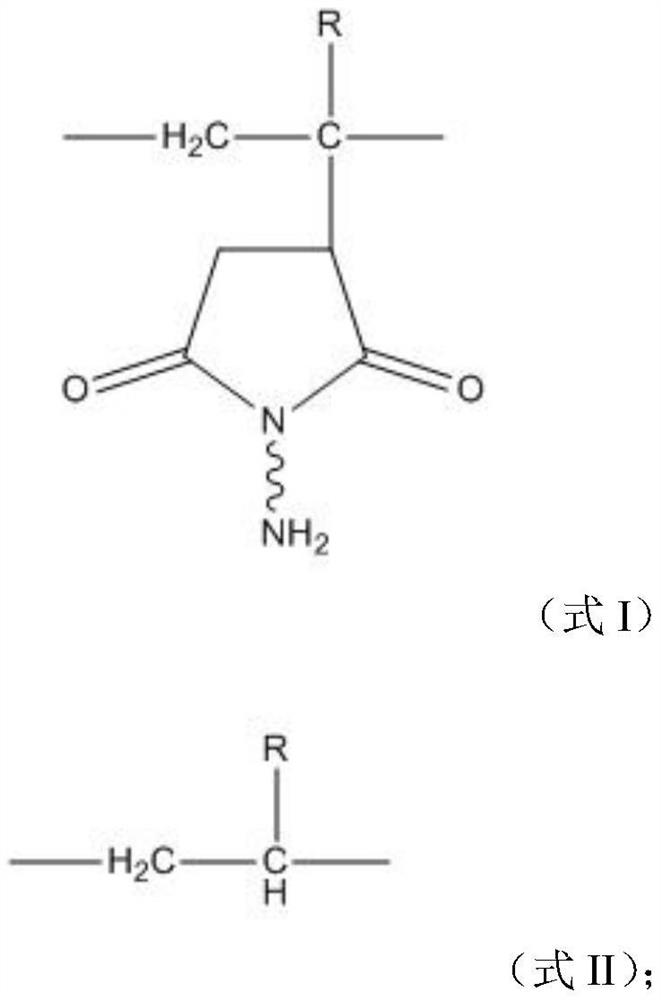

Method used

Image

Examples

preparation example Construction

[0050] As an example, the preparation method of the polyurethane urethane spinning stock solution includes:

[0051] Prepolymeting step: The solvent, polyol, polyisocyanate is sequentially added in the prepolymer, and the molar ratio of NCO / OH is controlled is greater than 1, and the prepolymerization reaction temperature is controlled above the melting point of the reactant, and the nitrogen protection during the reaction to obtain a prepolymer Solution;

[0052] The expanding step: Add the chain extender to the obtained prepolymer solution, stirred well, dissolve, and continue to be completed into a polyurethaneurea solution;

[0053] In the above preparation step, conventional accessories aid, for example, an antioxidant, a stain, a surfactant, or the like, stir evenly, and prepared, and prepared polyurethane urethane spinning stock solution;

[0054] Among them, the addition of the additives is not particularly required, as long as the polyurethane elastic fibers are deterio...

Embodiment 1

[0081] The dispersion and lubricant composition 1 containing the polymer A1 is added to a concentration of 100 kg of 100 kg of polyurethaneurease solution, and the control polymer A1 accounts for 0.5% of the mass of the polyurethane elastic fiber, and the lubricant composition 1 comprises the mass of the polyurethane elastic fiber. 0.5%; and stir mixed at a constant temperature of 45 ° C for 10 hours, and the mixed spinning stock solution was obtained after the maturation was completed. The spinning stock solution is delivered to the spinneret assembly, and then forms a liquid fine flow through the spinneret pore; the stock fine flow passes through a spinning of 260 ° C to the initial fiber; 48 primary fibers through the air fake twist The bundle of twisted, which is 1.2 times the drafting effect by the guide wire, finally wound by the winding machine to obtain 560 oxythane elastic fiber sample 1.

Embodiment 2

[0083] The same experimental method as in Example 1 is in that the polymer A1 is replaced with polymer A2, and the polymer A2 accounts for 2% of the mass of the polyurethane elastic fibers, and the lubricant composition 1 is replaced with a lubricant composition. 2, the lubricant composition 2 accounts for 0.1% of the mass of the polyurethane elastic fiber, and the polyurethane elastic fibers prepared are sample 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com