Metallurgical bonding glass-encapsulated diode structure and production method

A technology of glass-encapsulated diodes and production methods, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., and can solve the problem of weak ability to resist forward surge current and reverse surge power, narrow operating temperature range, and low resistance to soldering temperature and other issues, to achieve the effect of broadening compatibility, resistance to welding heat requirements, and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

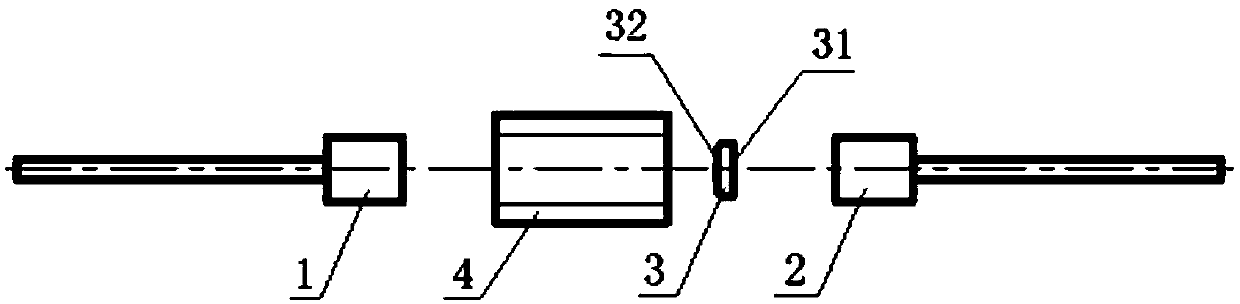

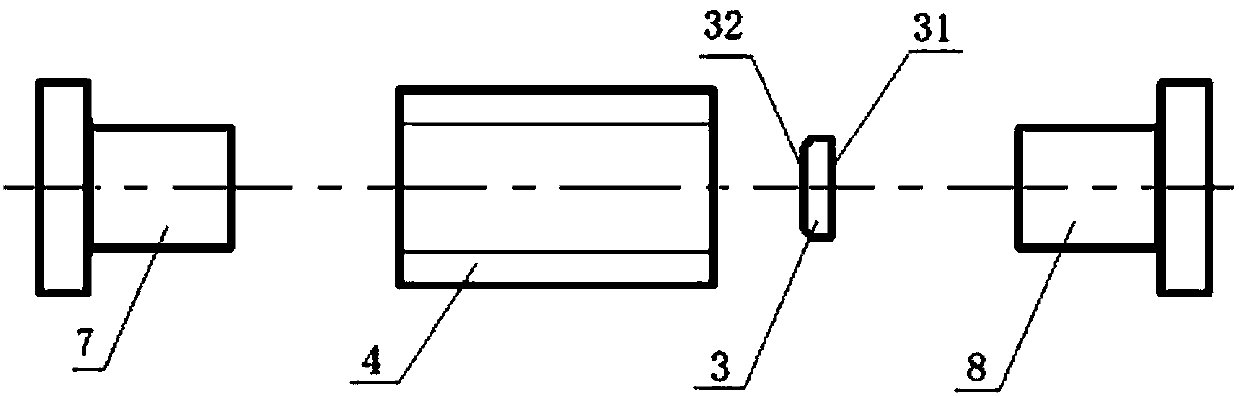

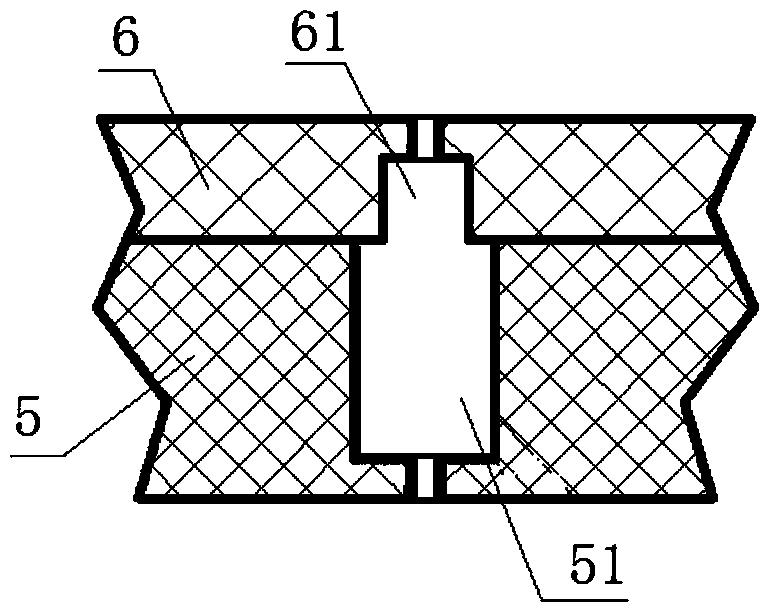

[0042] Such as figure 1 , figure 2 As shown, a metallurgically bonded metallurgically bonded glass-encapsulated diode structure includes an electrode A1, an electrode B2, a chip 3 and a glass tube 4, and the electrode A1, electrode B2 and chip 3 are all arranged in the glass tube 4, and the The upper end and the lower end of the chip 3 are respectively provided with an upper surface metallization layer 31 and a lower surface metallization layer 32, the upper surface metallization layer 31 is connected to the electrode B2, and the lower surface metallization layer 32 is connected to the electrode A1. 3 and electrode A1 and electrode B2 are electrically connected by diffusion welding, and the transition layer materials for diffusion welding are the upper surface metallization layer 31 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com