Deep denitrification process and equipment for high-nitrogen-content organic wastewater

A technology for organic waste water and deep denitrification, applied in water pollutants, water/sewage treatment, light water/sewage treatment, etc., can solve the problems of high price of bipolar membrane, high cost of waste water treatment, high environmental requirements, etc., to achieve treatment The process is safe and environmentally friendly, improves the efficiency of sewage treatment, and does not produce secondary pollution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

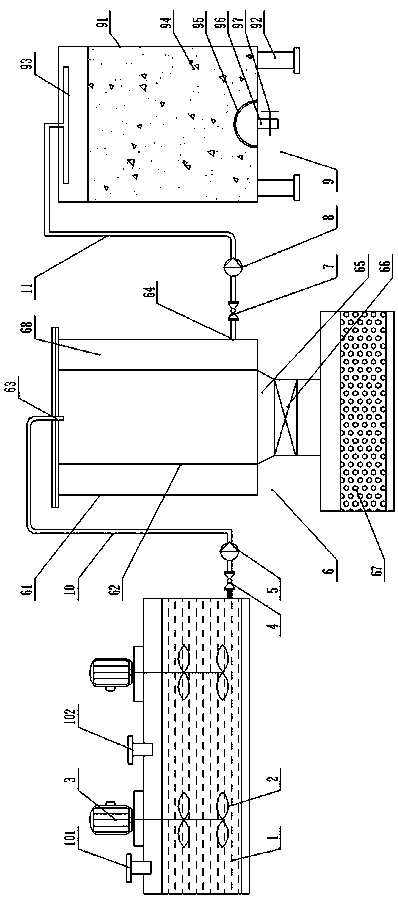

Image

Examples

Embodiment 1

[0038] A deep denitrification process for high-nitrogen organic wastewater, comprising the following steps: chemical precipitation, zeolite filtration, electrodialysis reaction, and post-treatment.

[0039](1) Chemical precipitation: the chemical precipitation, with MgCl 2 h 22 o 14 、CH 3 COO(NH 4 ) 2 and Na 3 PO 4 ﹒ 12H 2 O is a precipitant, according to the molar ratio Mg 2+ : NH 4 + :PO 4 3- Add a precipitating agent at a ratio of 0.8:1:1, then add 6g sodium bicarbonate and 3g sodium hydroxide solution to the filtrate to adjust the pH value, use a turbine stirrer to stir for 15min, then let it stand for 30min, and the stirring speed is 70- 80RPM;

[0040] After standing still, filter the precipitate through a 300-400 mesh filter, and filter the filtered filtrate with zeolite.

[0041] (2) Zeolite filtration: for the zeolite filtration, first, the natural zeolite is beneficiated, crushed, screened, and roasted, then mixed with kaolin, polyvinylamine, and water...

Embodiment 2

[0049] A deep denitrification process for high-nitrogen organic wastewater, comprising the following steps: chemical precipitation, zeolite filtration, electrodialysis reaction, and post-treatment.

[0050] (2) Chemical precipitation: the chemical precipitation, with MgCl 2 h 22 o 14 、CH 3 COO(NH 4 ) 2 and Na 3 PO 4 ﹒ 12H 2 O is a precipitant, according to the molar ratio Mg 2+ : NH 4 + :PO 4 3- Add a precipitant at a ratio of 0.9:1:1, then add 6.5g sodium bicarbonate and 3.2g sodium hydroxide solution to the filtrate to adjust the pH value, use a turbine stirrer to stir for 15min, and then let it stand for 30min. The stirring speed is 75-85RPM;

[0051] After standing still, filter the precipitate through a 300-400 mesh filter, and filter the filtered filtrate with zeolite.

[0052] (2) Zeolite filtration: for the zeolite filtration, first, the natural zeolite is beneficiated, crushed, screened, and roasted, then mixed with kaolin, polyvinylamine, and water at ...

Embodiment 3

[0059] A deep denitrification process for high-nitrogen organic wastewater, comprising the following steps: chemical precipitation, zeolite filtration, electrodialysis reaction, and post-treatment.

[0060] (4) Chemical precipitation: the chemical precipitation, with MgCl 2 h 22 o 14 、CH 3 COO(NH 4 ) 2 and Na 3 PO 4 ﹒ 12H 2 O is a precipitant, according to the molar ratio Mg 2+ : NH 4 + : PO 4 3- Add a precipitant at a ratio of 1:1:1, then add 7g of sodium bicarbonate and 3.5g of sodium hydroxide solution to the filtrate to adjust the pH value, use a turbine stirrer to stir for 15min, then let it stand for 30min, and the stirring speed is 80 -90RPM;

[0061] After standing still, filter the precipitate through a 300-400 mesh filter, and filter the filtered filtrate with zeolite.

[0062] (2) Zeolite filtration: for the zeolite filtration, first, the natural zeolite is beneficiated, crushed, screened, and roasted, then mixed with kaolin, polyvinylamine, and water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com