Oyster attachment substrate made of lightweight concrete and preparation method thereof

A light-weight concrete and attachment-based technology, which is applied to the intersection of marine sessile organisms and marine concrete, can solve the problems of increased seawater alkalinity, dark gray of cement attachment base, and no consideration of water consumption, so as to reduce labor costs. , the effect of reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

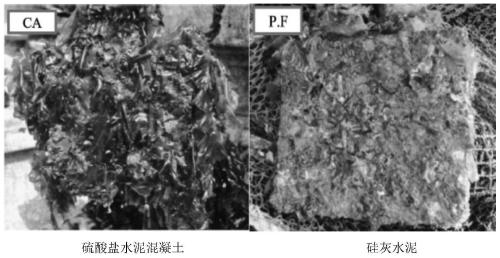

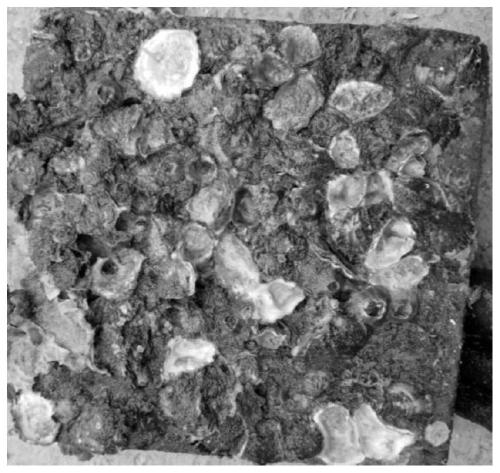

Problems solved by technology

Method used

Image

Examples

Embodiment 1

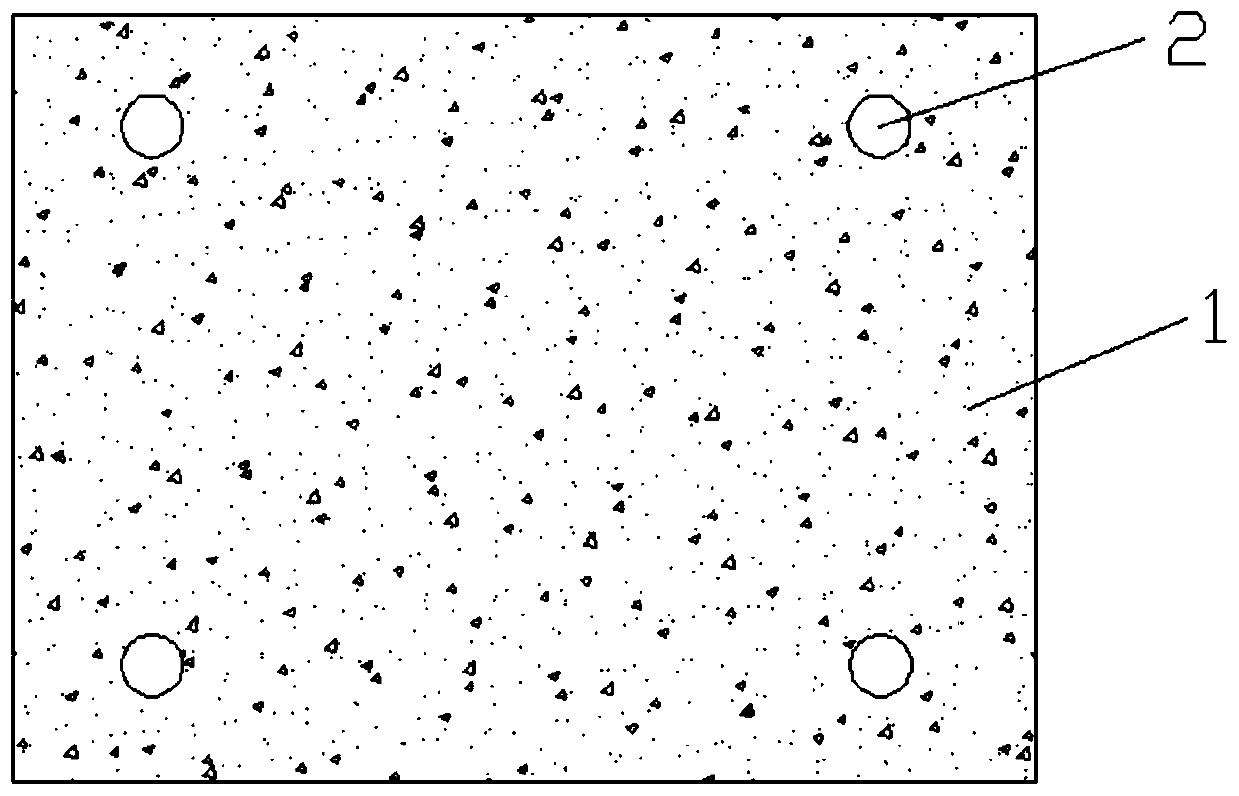

[0049] Example 1: Ordinary Portland cement concrete mix ratio, ordinary Portland cement, lightweight coarse aggregate, lightweight fine aggregate, water and polycarboxylate superplasticizer powder weight proportions are: 29.37%, 33.53% %, 24.48%, 12.59%, 0.03%.

[0050] The lightweight coarse aggregate described herein is one or both of light porous basalt and light ceramsite with a maximum particle size less than 20 mm. The lightweight fine aggregate is one or both of crushed zeolite and lightweight ceramic sand, with a particle size of 0.2 mm to 5 mm and good gradation. The water should meet the concrete water standard (JGJ63-2006), Cl- content 4.5, and have little effect on the initial setting time difference and final setting time, strength and permeability of cement. And the above materials selected in Examples 1-15 are the same.

Embodiment 2

[0051] Example 2: Baseline concrete mix ratio, the weight ratio of ordinary Portland cement, silica fume, blast furnace slag powder, lightweight coarse aggregate, lightweight fine aggregate, water and polycarboxylate superplasticizer powder is: 17.62 %, 1.47%, 10.28%, 33.53%, 24.48%, 12.59%, 0.03%.

Embodiment 3

[0052] Embodiment 3: The weight ratio of unmodified dark pigment, ordinary Portland cement, silica fume, blast furnace slag powder, lightweight coarse aggregate, lightweight fine aggregate, water and polycarboxylate water reducer powder is as follows: : 1.47%, 17.62%, 1.29%, 8.99%, 33.53%, 24.48%, 12.59%, 0.03%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com