Optical material composition, multifunctional composite board, production process of the multifunctional composite board and backlight module

A technology of optical materials and compositions, applied in optics, optical components, filters, etc., can solve the problems of insufficient backlight brightness, various optical properties can not fully meet the backlight module, large loss of light, etc., to achieve excellent Light transmittance and diffusivity, environmentally friendly display or lighting equipment, indicating the effect of structural diversification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] In this optical material composition, the GPPS of 90wt%, the light diffusing agent of 3wt%, the abrasive agent of 6wt% and the dispersant of 0.2wt%, the antioxidant of 0.2wt%, the ultraviolet absorber of 0.4wt%, 0.05wt% % lubricant and 0.15 wt% filler.

Embodiment 2

[0060] The composition includes 92wt% of GPPS, 2wt% of light diffusing agent, 5wt% of sanding agent and 0.1wt% of dispersant, 0.3wt% of antioxidant, 0.3wt% of ultraviolet light absorber, 0.1wt% of lubricating agent agent and 0.2wt% filler.

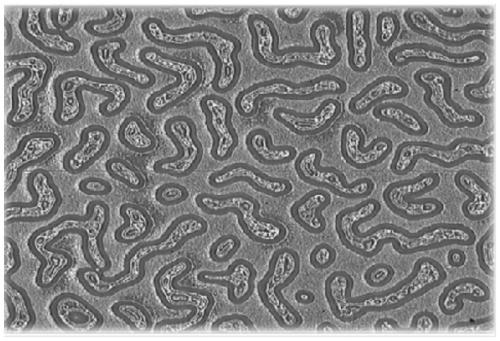

[0061] In the second aspect, the present application provides a multifunctional composite board prepared by using the optical material composition, and the multifunctional composite board is prepared by uniformly mixing the composition, extruding, and forming.

[0062] Further, the multifunctional composite board has a double-layer structure, one of which contains at least a light diffusing agent, and the other layer contains at least GPPS, and the two layers are formed into an integrated composite board by extrusion.

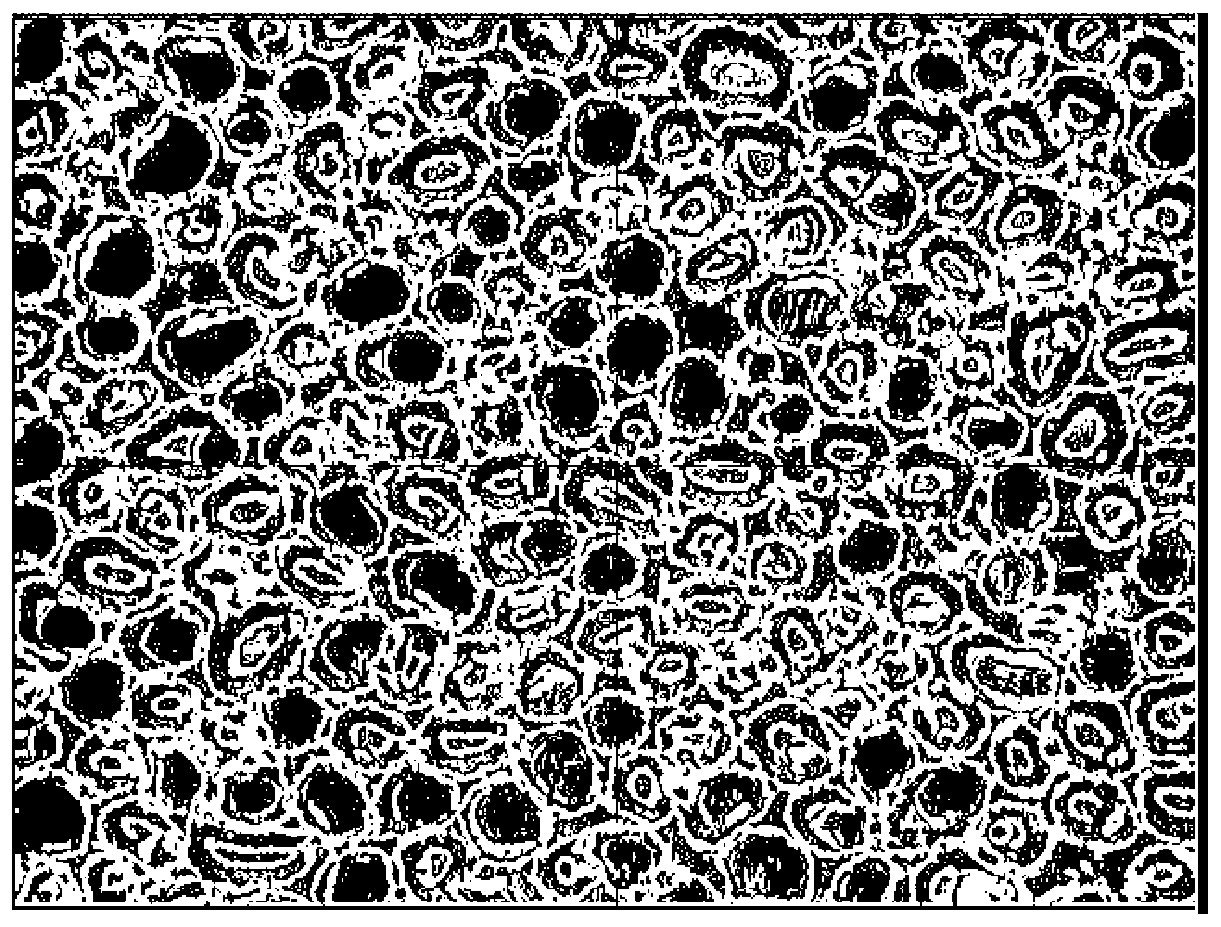

[0063] Further, the upper and lower surfaces of the multifunctional composite board are provided with dot structures for guiding light, wherein the dot structures on the upper and lower surfaces are any one or both of conve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com