High pressure spray characteristics test system under high temperature and high back pressure

A technology of high-pressure spraying and characteristic testing, which is used in engine testing, machine/structural component testing, charging system, etc., to achieve the effect of simple and convenient operation, accurate and efficient test results, and guaranteeing safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

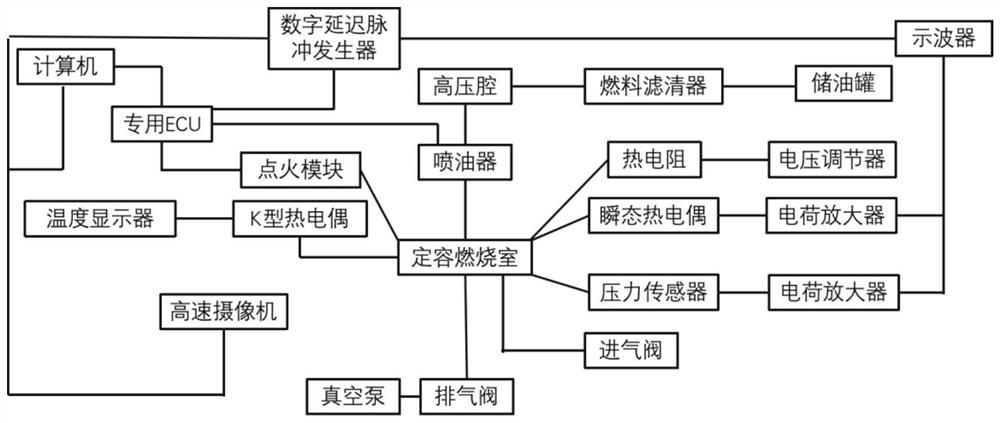

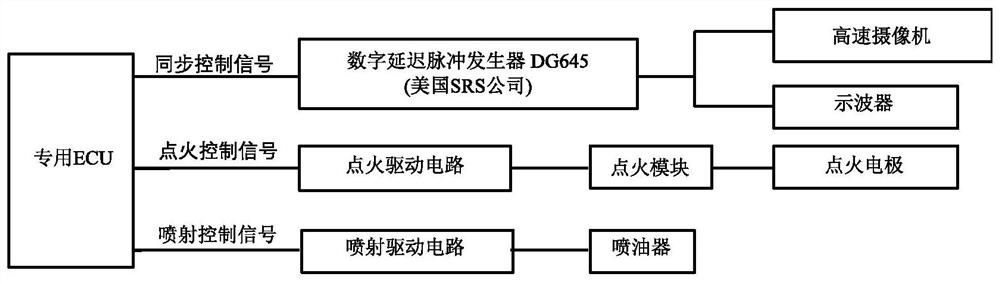

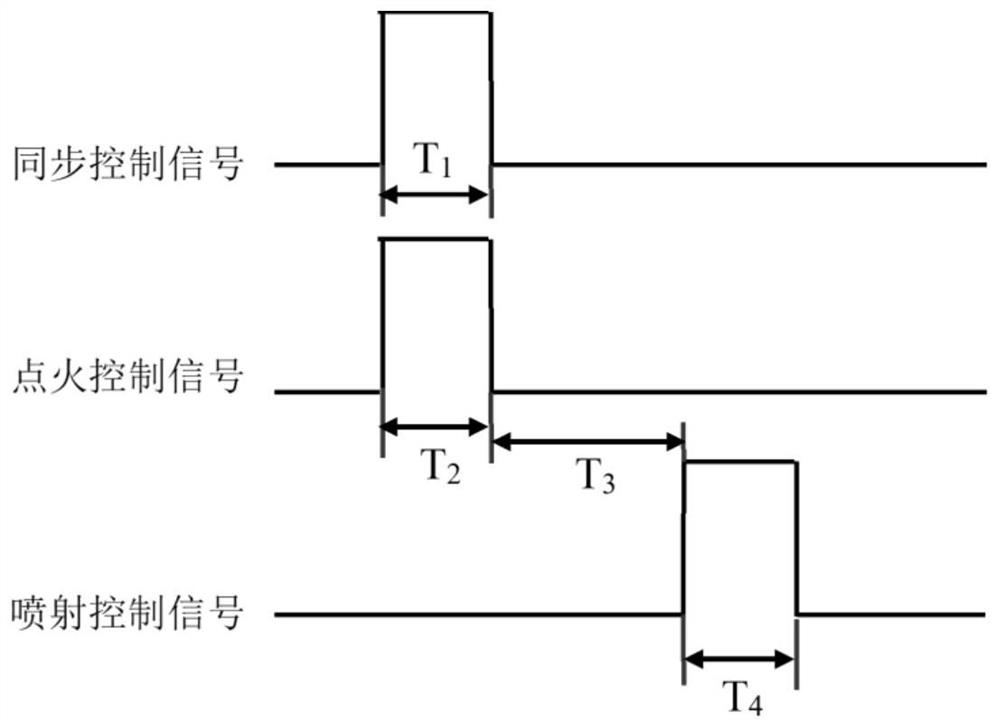

[0027] Such as figure 1 Shown is a schematic structural diagram of the high-pressure spray characteristic testing system under high temperature and high back pressure of the present invention, including a synchronous control system, a high-speed camera, a constant-volume combustion chamber, and a heating system installed with the constant-volume combustion chamber, and transient high-temperature and high-pressure measurement System, ignition and fuel injection system; the constant volume combustion chamber is a hollow cavity structure with a combustion chamber, which provides a cavity for measuring spray characteristics, and several installation grooves and installation through holes are provided on its outer wall, and the installation through holes A sealing assembly that seals the installation through hole is detachably installed inside; an optical window is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com