Terahertz wavefront phase control device based on liquid crystal and wire-grid metasurface

A metasurface and control device technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as limiting practical applications, high applied voltage, and slow modulation rate of devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

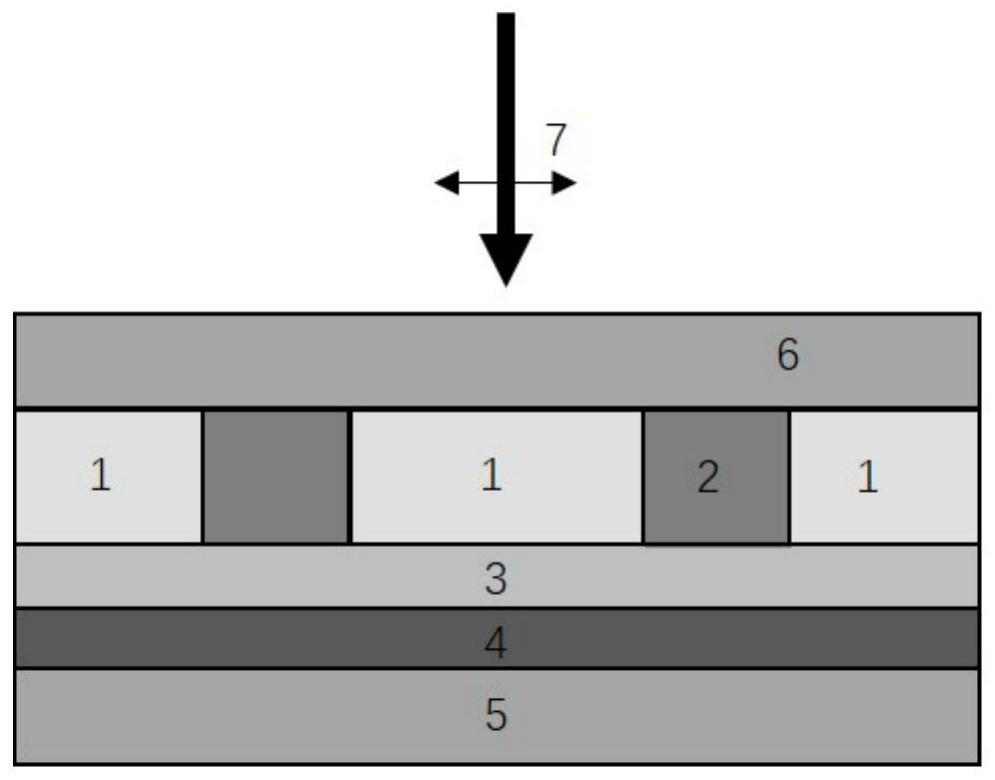

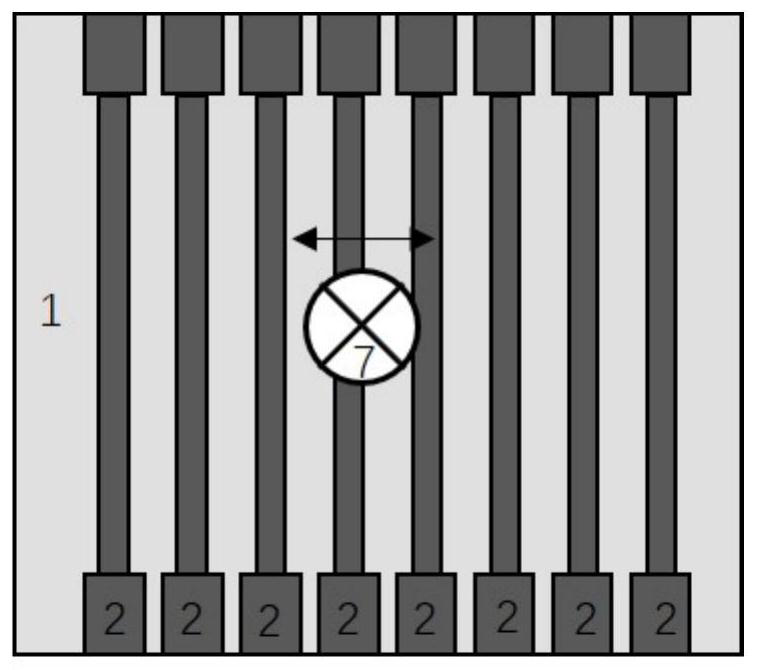

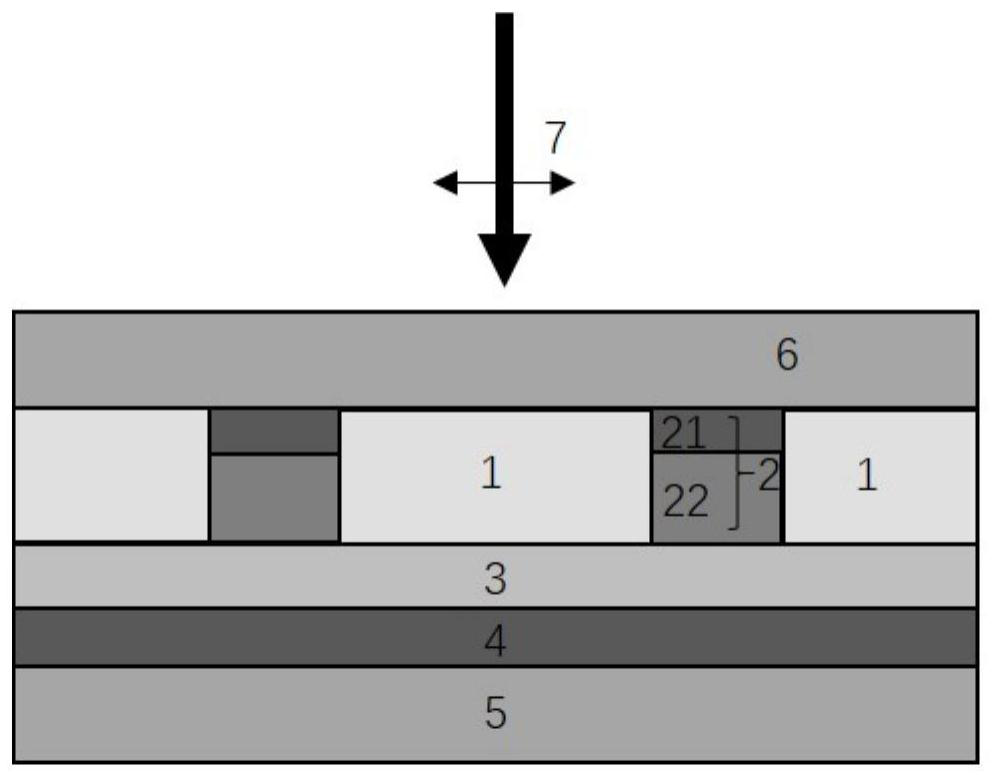

[0030] In the first implementation example, the operating frequency of the phase modulator is 0.5 THz. Such as image 3 As shown, the liquid crystal material selected for the liquid crystal 1 is E7, and when the applied voltage is 0-15V, the refractive index change in the terahertz band is about 1.55-1.7. Gold is selected as the constituent material of the reflector 4, and its thickness is 100 nanometers. Al2O3 is selected as the material for the dielectric isolation layer 3 with a thickness of 200 nanometers. The metasurface electrode 2 selects silicon and gold as the composite layer of the constituent materials, the gold thickness of the conductive layer 21 is 100 nanometers, and the silicon doping concentration in the single layer 22 that is transparent to the application band and can be made of conductive materials is 1.4×10 14 A single layer 22 has a thickness of 130 microns per cubic centimeter. The wire-grid metasurface electrode 2 adopts such as Figure 4 For the i...

Embodiment 2

[0031] In the second implementation example, the working frequency of the phased array is 0.5 THz. The basic structure is as figure 2 , image 3 shown. The structure of the wire-grid metasurface electrode 2 and the way of applying voltage are as follows: Figure 9 As shown, each gate is independent of each other, and the voltage difference between adjacent gates can be independently controlled, and other configurations are consistent with the configuration of the phase modulator in the first implementation example. Such as Figure 10 As shown, since the voltage difference between adjacent gates can be independently controlled, through the device of this implementation example, the reflected terahertz beam 8 formed after the incident terahertz electromagnetic beam 7 with a set frequency in the p-polarization direction is reflected by the device can be Each pair of gates has the same gradient phase difference In turn, the beams reflected by adjacent grids produce wave pat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com