Production method for aligned ceramic sintered body, and flat sheet

A technology of sintered body and ceramics, which is applied to the production method of oriented ceramic sintered body and the field of flat sheets, and can solve problems such as adhesion spacer cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

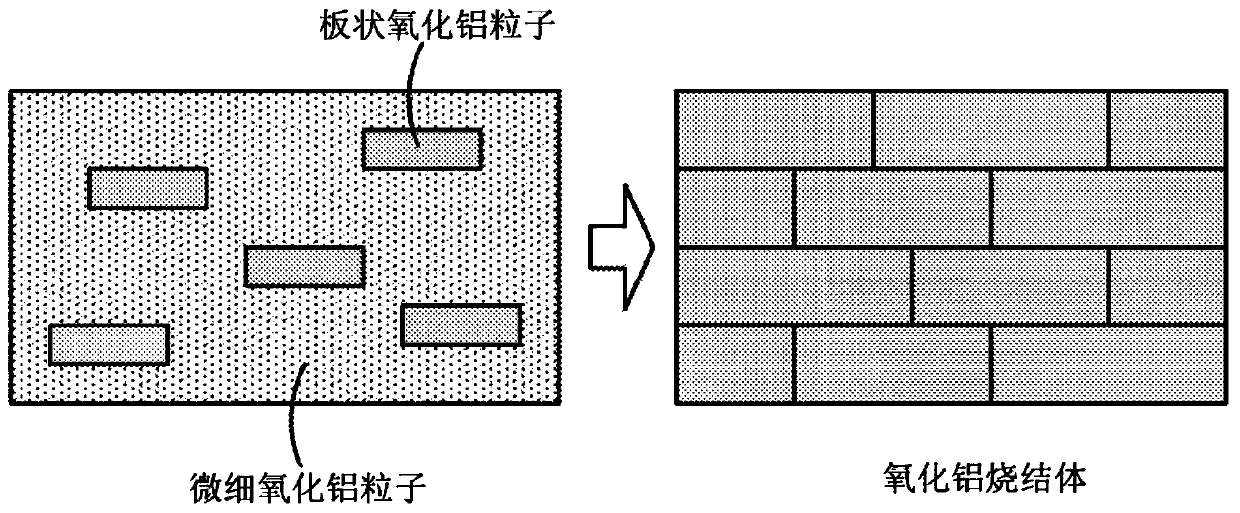

[0035] 1. Production of alumina sintered body

[0036] (1) Production of alumina molded body

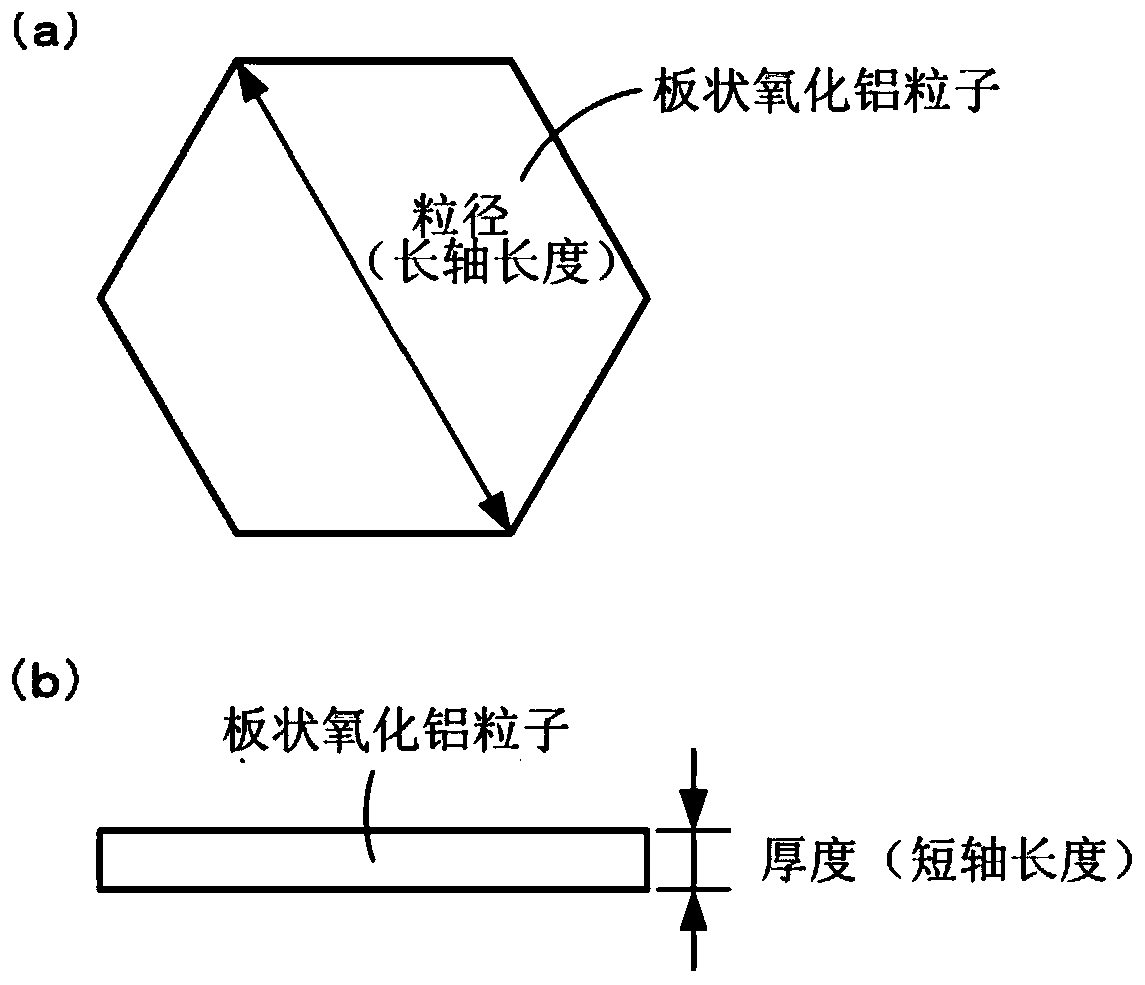

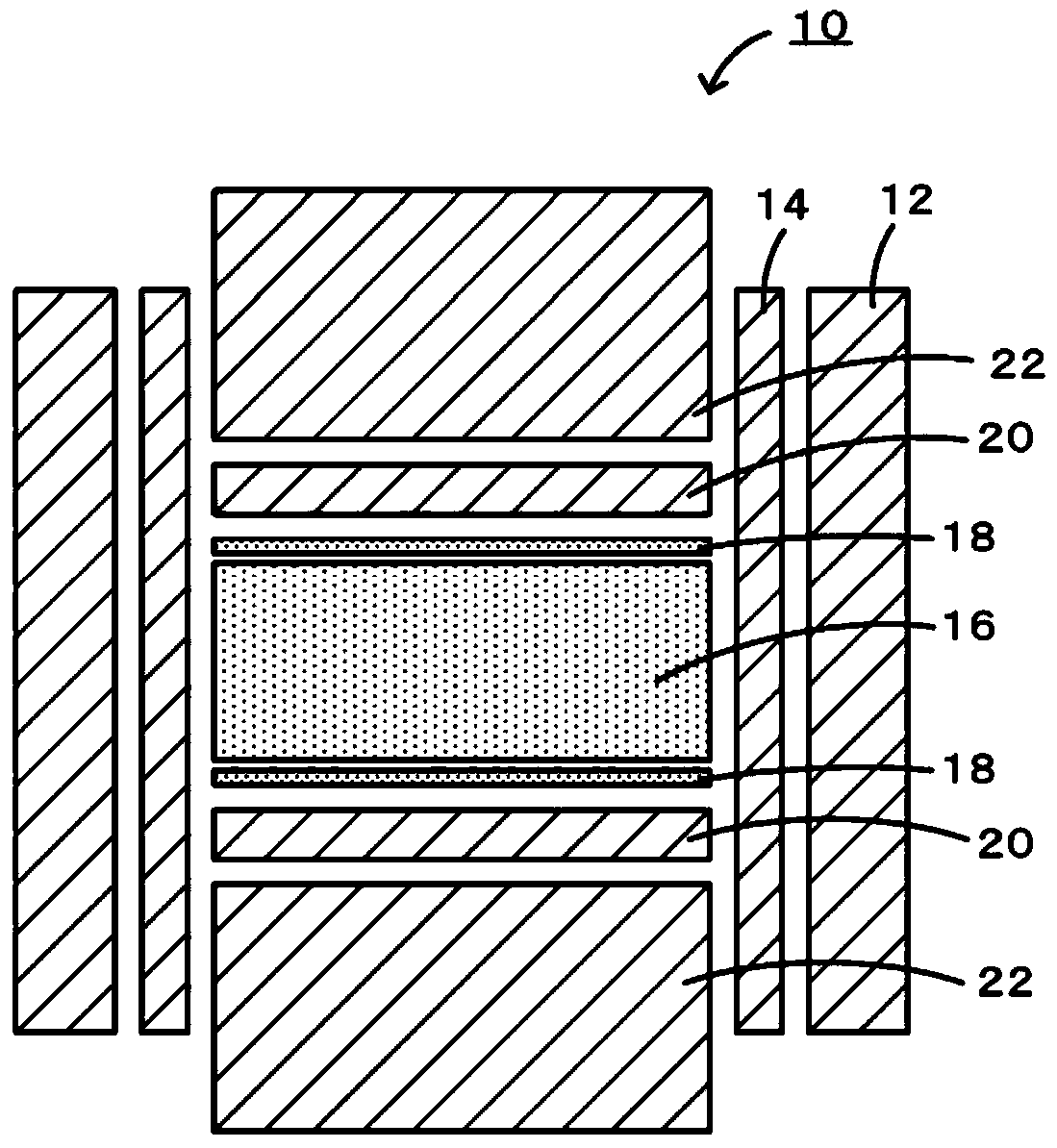

[0037] Mix 0.5 parts by mass of commercially available tabular alumina powder (YFA10030, manufactured by KinseiMatec, average particle diameter 10 μm, average thickness 0.35 μm, aspect ratio 29) and fine alumina powder (TM-DAR, average particle diameter 0.1 μm , Daming Chemical) 99.5 parts by mass to make mixed alumina powder. When the mass ratio of the platy alumina powder to the fine alumina powder is represented by T: (100-T), T=0.5. To 100 parts by mass of the mixed alumina powder, 0.0125 parts by mass (125 ppm by mass) of magnesium oxide (500A, manufactured by Ube Materials) and polyvinyl butyral (product number BM-2, Sekisui Chemical Co., Ltd.) as a binder were added. Industrial production) 7.8 parts by mass, bis(2-ethylhexyl) phthalate (manufactured by Kurokin Kasei) 3.9 parts by mass as a plasticizer, sorbitan trioleate (Rheodol SP -O30, manufactured by Kao) 2 parts by mas...

experiment example 2

[0061] In Experimental Example 2, commercially available plate-shaped graphite powder (SGP-3, SEC carbon, average particle diameter 3 μm) was used. Except for this, an alumina sintered body was produced in the same manner as in Experimental Example 1. The molded sheet of Experimental Example 2 had a maximum cross-sectional height Pt of 0.378 μm and a porosity of 51.6% (see Table 1 below). In addition, the XRC·FWHM of the outermost surface of the alumina sintered body was 2.1°, and the XRC·FWHM of the surface (inside) ground to 100 μm was also 2.1° (see Table 1 below). Thus, the obtained alumina sintered body is an oriented alumina sintered body, and the crystal orientation of the surface of the alumina sintered body is the same as the crystal orientation of the interior.

experiment example 3

[0063] In Experimental Examples 1 and 2, commercially available graphite powder was used as the raw material of the molded sheet, but in Experimental Example 3, commercially available boron nitride (USP-S2, manufactured by Showa Denko, average particle size 0.6 μm) was used instead . Except for this, an alumina sintered body was produced in the same manner as in Experimental Example 1. The molded sheet of Experimental Example 3 had a maximum cross-sectional height Pt of 0.413 μm and a porosity of 25.3% (see Table 1 below). In addition, the XRC·FWHM of the outermost surface of the alumina sintered body was 2.2°, and the XRC·FWHM of the surface (inside) ground to 100 μm was also 2.2° (see Table 1 below). Thus, the obtained alumina sintered body is an oriented alumina sintered body, and the crystal orientation of the surface of the alumina sintered body is the same as the crystal orientation of the interior.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com