Electrolytic copper foil, method for producing same, and anode for high capacity li secondary battery including same

A technology of electrolytic copper foil and anode, applied in the field of electrolytic copper foil, which can solve the problems of increasing surface resistance and achieve high discharge capacity retention and low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, preferred embodiments of the present invention will be described with reference to the accompanying drawings.

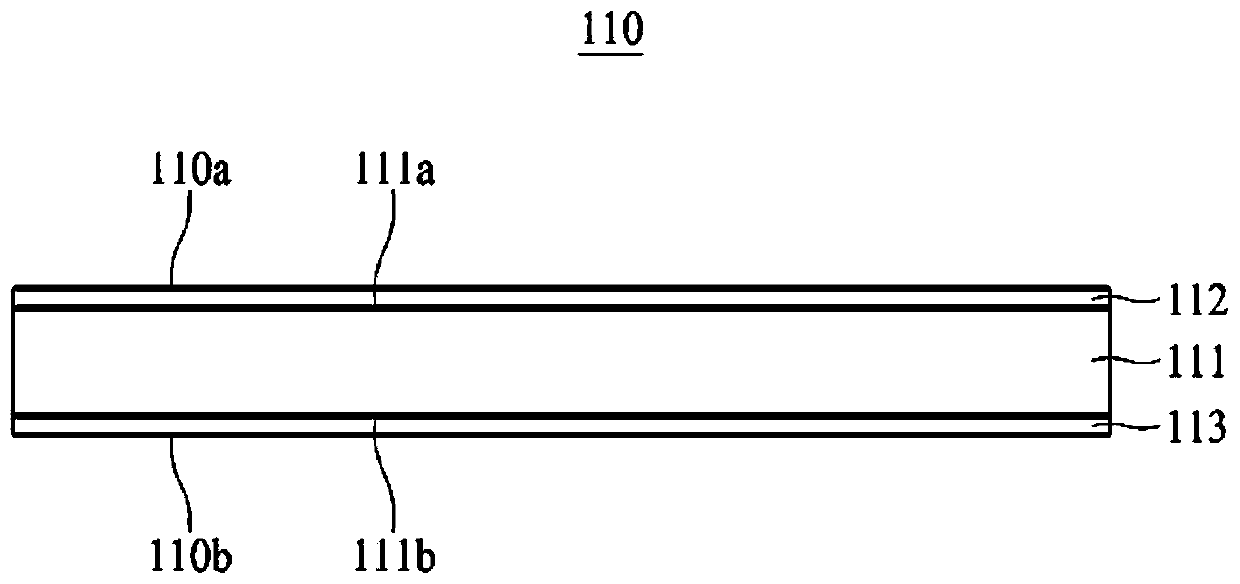

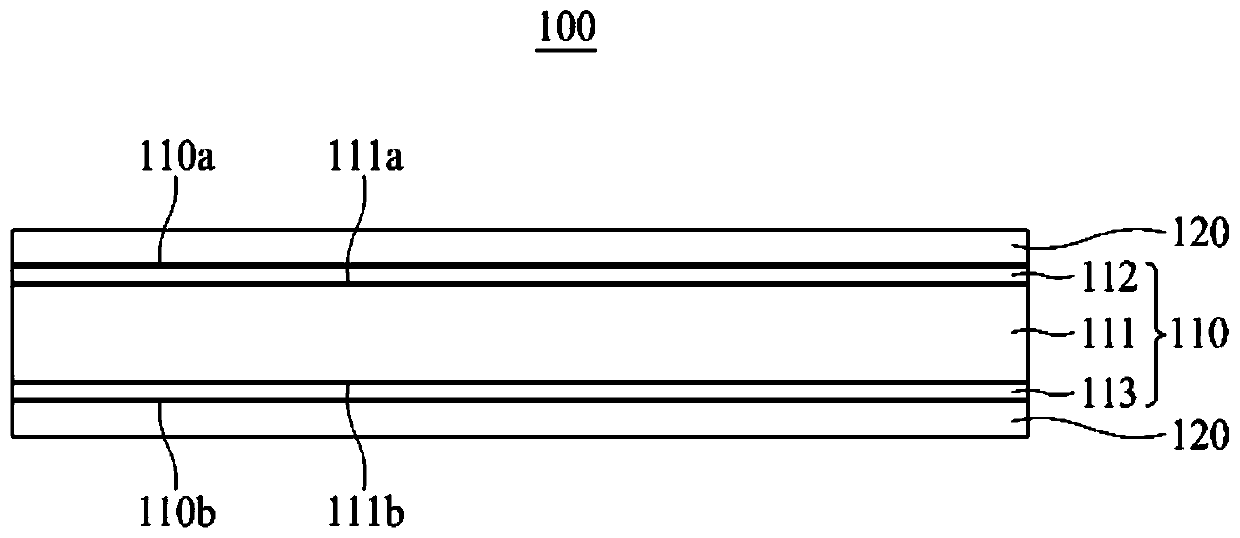

[0031] figure 1 is a schematic diagram showing a cross-sectional structure of an electrolytic copper foil according to an embodiment of the present invention.

[0032] refer to figure 1 , the electrolytic copper foil 110 has a first exposed surface 110a and a second exposed surface 110b opposite to the first exposed surface 110a, and includes: a first protective layer 112 forming the first exposed surface 110a; forming the second exposed surface 110a; the second protective layer 113 on the exposed surface 110b; and the copper film 111 between the first protective layer 112 and the second protective layer 113 .

[0033] In the present invention, the electrolytic copper foil 110 has a predetermined thickness, for example, a thickness of 4 μm to 30 μm. In the case where the thickness of the copper foil is less than 4 μm, it leads to a decrease in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com