Strip-shaped composite seeder for corn and soybeans

A seeder, soybean technology, applied in the direction of fertilizers and seeding equipment, planting methods, agricultural machinery and tools, etc., can solve the problems of difficult seeder promotion, failure to form an integration, and affect seeding operations, etc., to reduce the weight of the machine and reduce winding , Reduce the effect of occupying space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

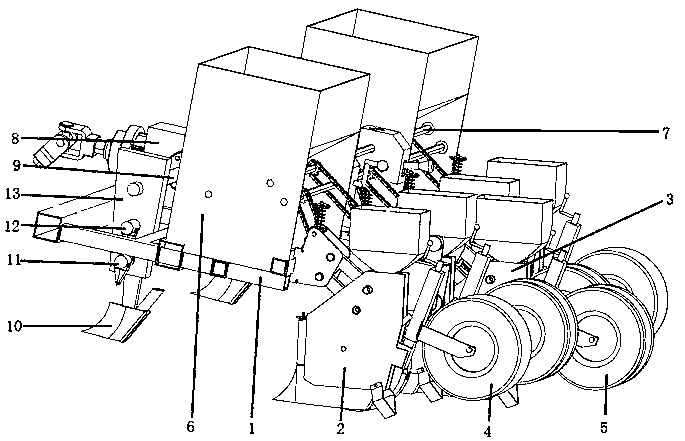

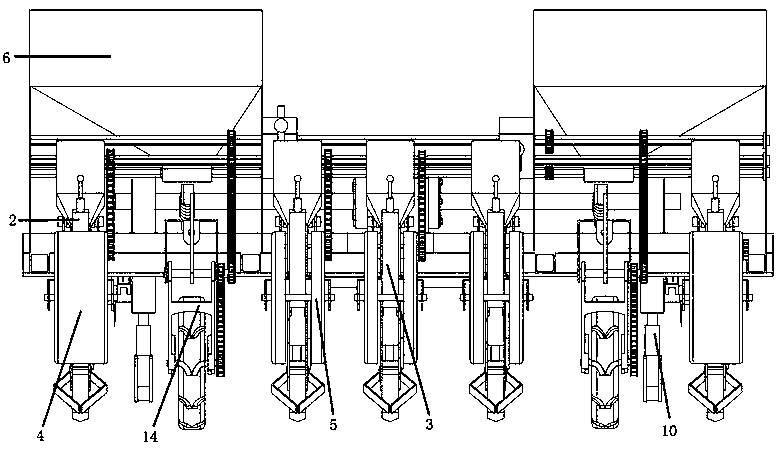

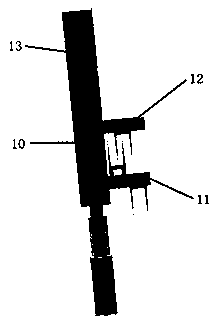

[0020] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

[0021] During operation, the driving wheel 14 contacts with the ground to generate power, and the power is transmitted to the hexagonal transmission shaft 7 through the chain transmission, and each hexagonal transmission shaft 7 is mutually transmitted, and a part of the power transmission is transmitted to the corn sowing unit 2 and the soybean sowing unit 3, Drive the seeding disc to rotate to sow, and another part of power is transmitted to the fertilizer box 6 to ensure that the outer groove wheel of the fertilizer discharge at the bottom rotates the fertilizer, and then falls into the fertilization ditch opener 10 to fertilize.

[0022] In a preferred embodiment, the gear box 8 transmits the power from the tractor to the gear box 13 via...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com