Dust removal and comprehensive utilization system special for organic fertilizer production line

A production line and organic fertilizer technology, applied in the direction of combined devices, steam generation, lighting and heating equipment, etc., can solve the problems of high dust concentration, blockage of filter bag mesh, large sticky dust, etc., and achieve the effect of increasing economic benefits and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

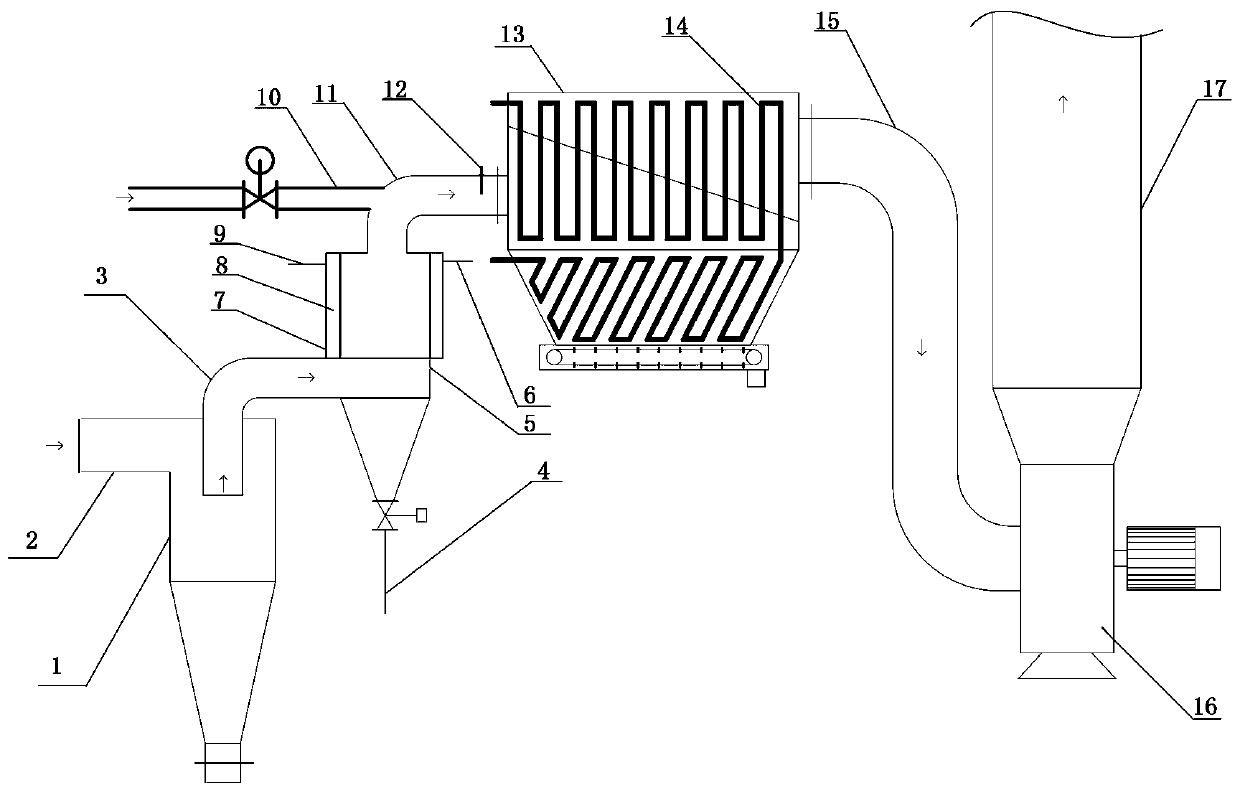

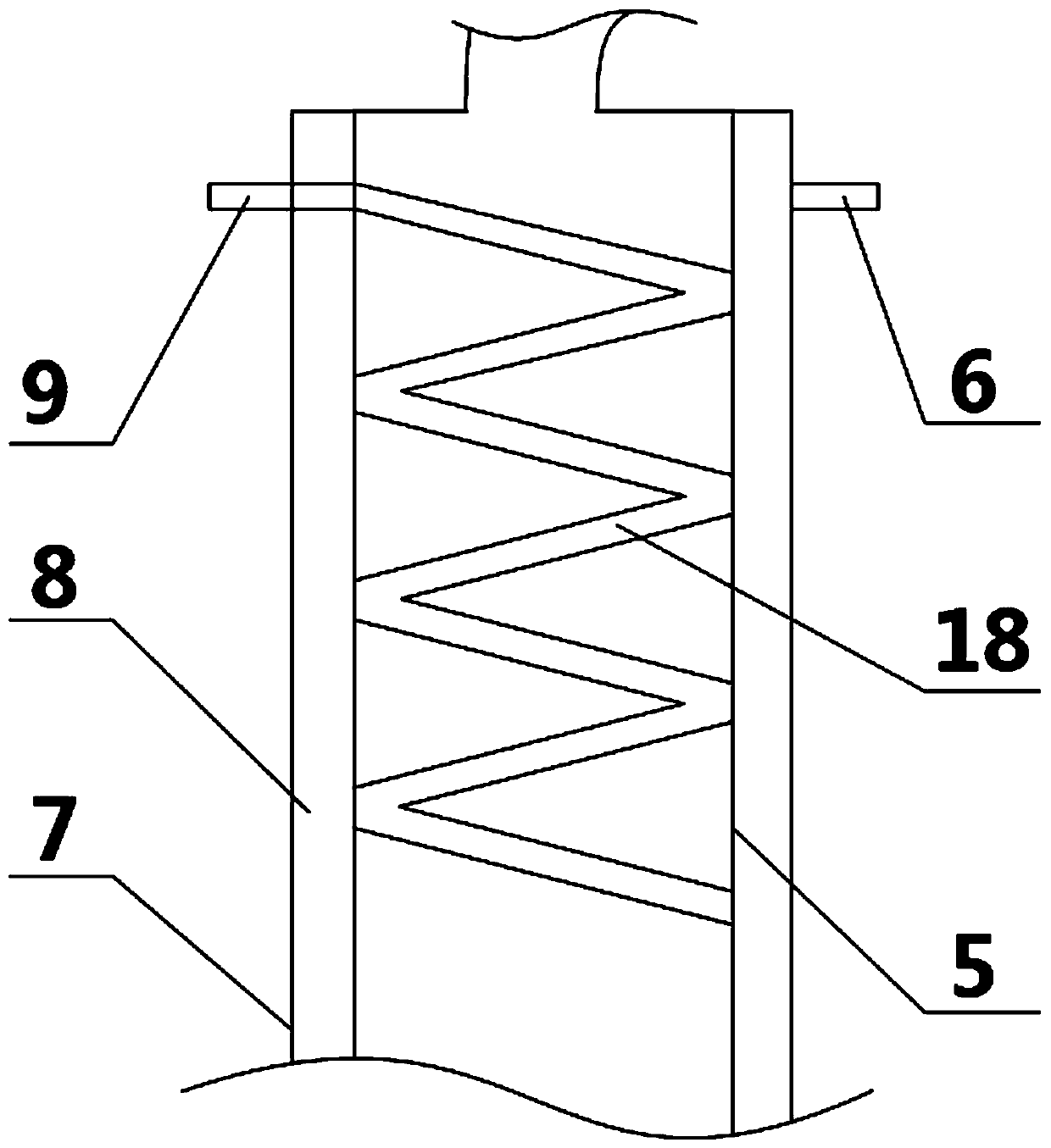

[0019] Such as figure 1 , The embodiment of the present invention includes a primary cyclone dust collector 1 and a secondary cyclone dust collector 5, and a dust inlet pipe 2 is installed on one side of the upper end of the primary cyclone dust collector 1. One side of the lower end of the cylinder section of the secondary cyclone dust collector 5 is connected to the upper end of the first-stage cyclone dust collector 1 through the first transition pipe 3, and the end of the first transition pipe 3 connected to the first-stage cyclone dust collector 1 goes deep into a The height inside the cyclone dust collector 1 and lower than the inlet end of the dust inlet pipe 2.

[0020] The organic fertilizer drying dust first enters the first-level cyclone dust collector 1 through the dust inlet pipe 2 for first-level dust removal. Drop about 60-70% of the dust.

[0021] The upper port of the secondary cyclone dust collector 5 is connected to the dust inlet end of the bag filter 13 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com