Concrete waste recovering device

A technology of concrete waste and recycling device, applied in clay preparation device, cement mixing device, grain processing and other directions, can solve the problems of waste, difficult degradation, large volume of concrete waste, etc., and achieve the effect of reducing production cost and avoiding waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0036] This example:

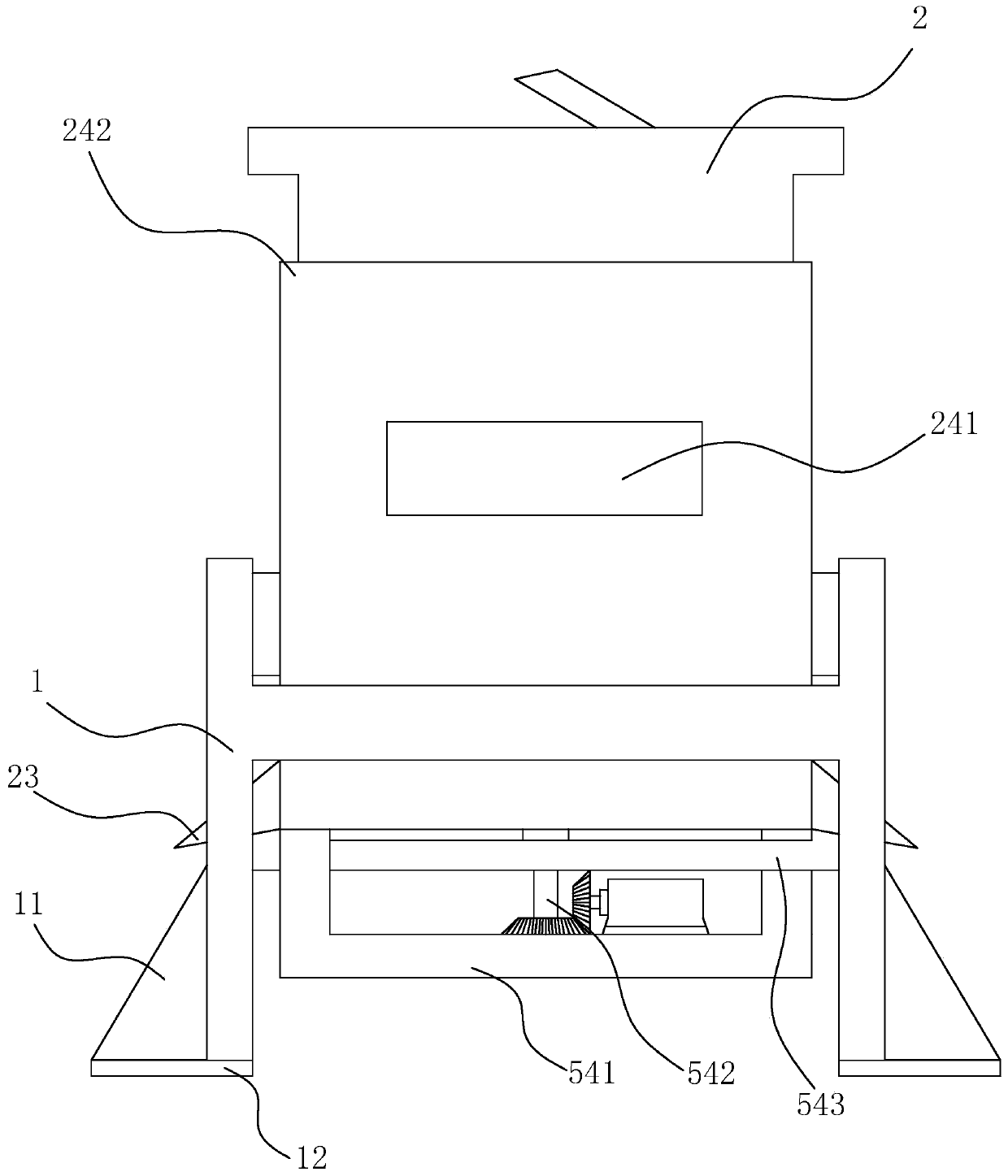

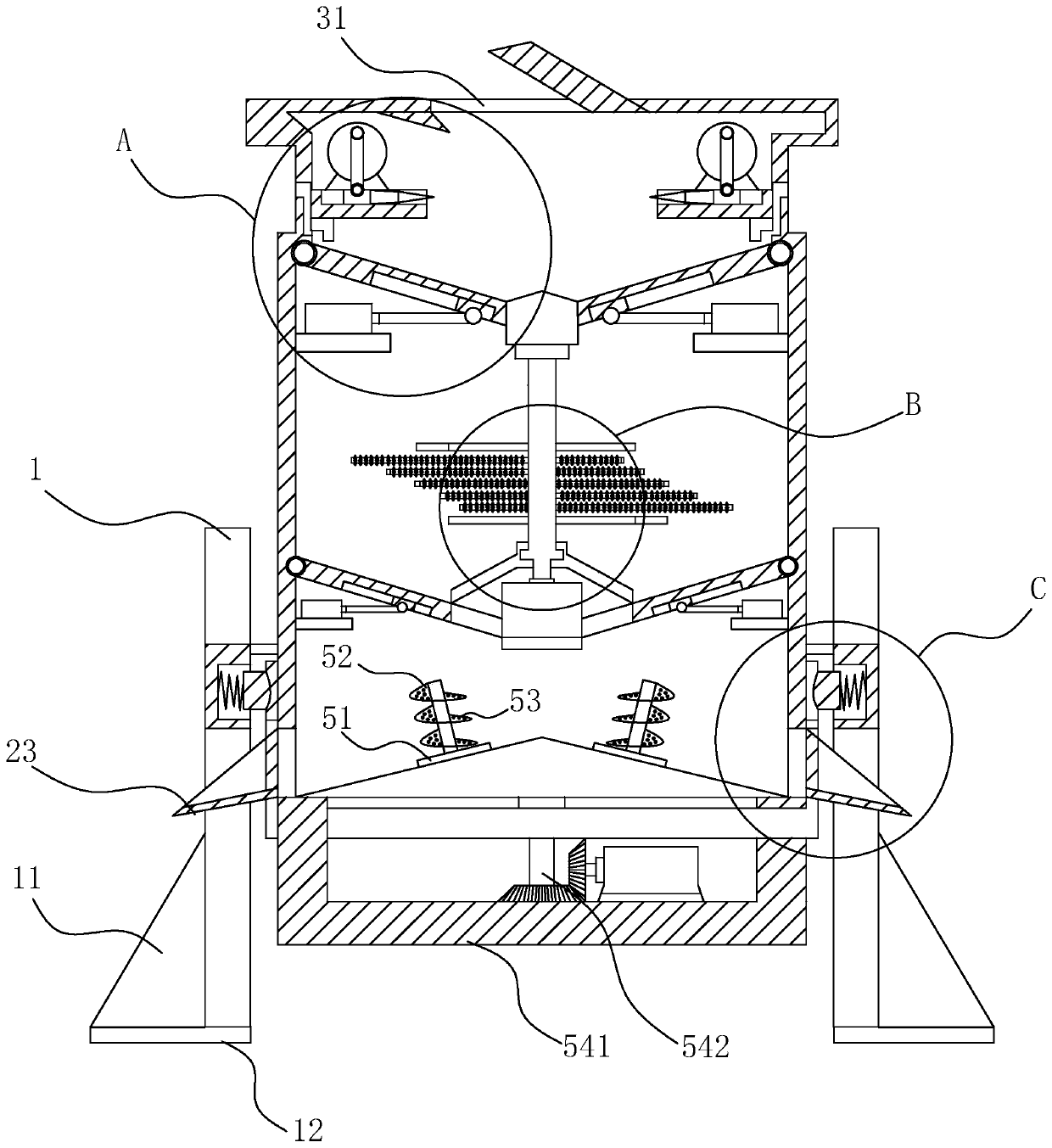

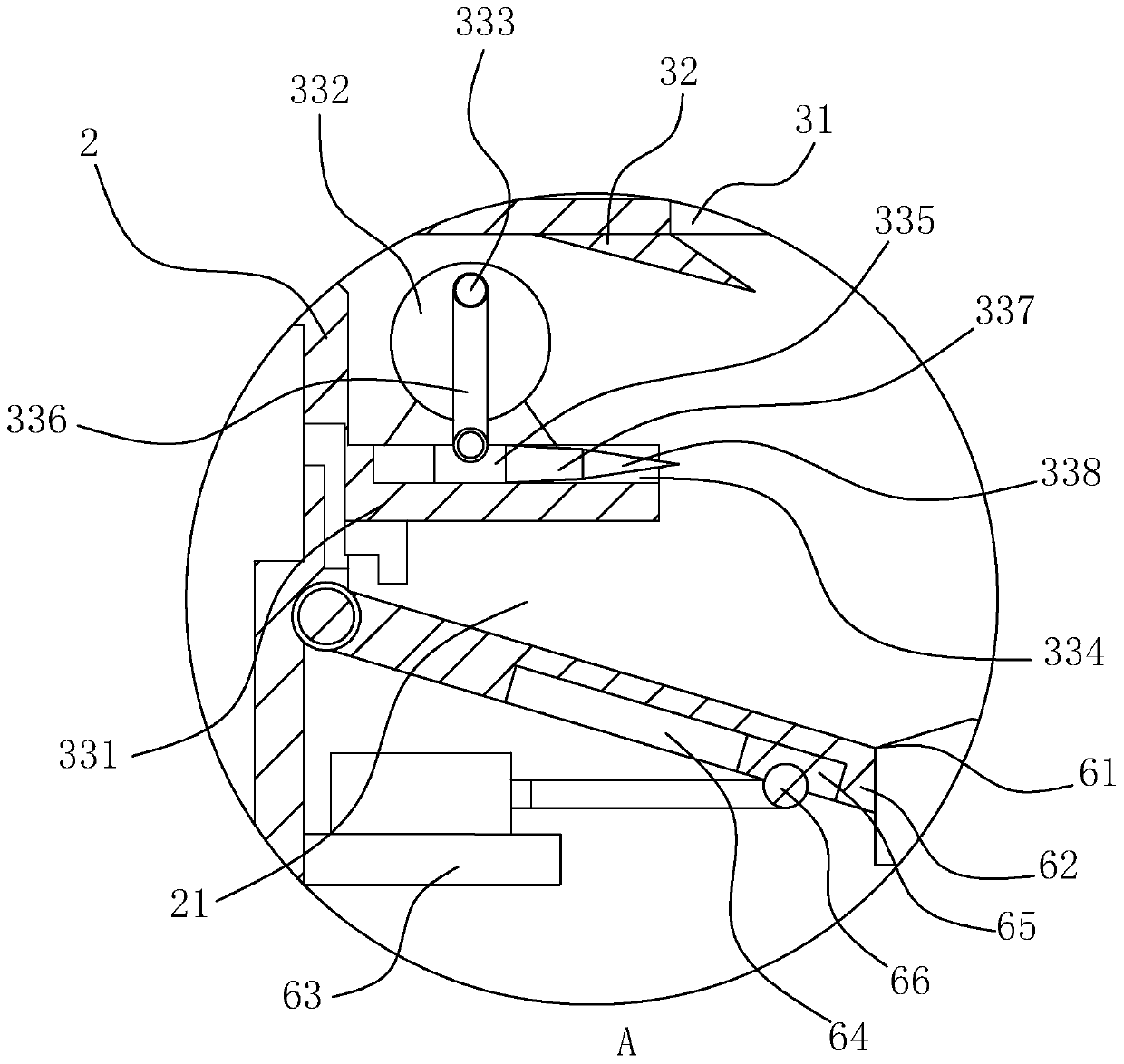

[0037] A concrete waste recovery device, such as figure 1 As shown, it includes a mounting frame 1, a loading box 2 and a waste recycling assembly.

[0038] The mounting frame 1 is set on the working ground in the working environment, and the bottom leg of the mounting frame 1 is provided with a plurality of auxiliary support rods 11, and the multiple auxiliary support rods 11 form a triangular shape with the legs of the mounting frame 1. While being fixed on the installation frame 1, these auxiliary support rods 11 can effectively stabilize the installation frame 1, and avoid the possible instability of the installation frame 1 when the concrete waste recovery device is working, thereby causing the concrete waste recovery device to collapse. The concrete waste recovery device is damaged, and at the same time, at the bottom of the aux...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com