Composite oil displacement agent for increasing recovery ratio of low-permeability reservoir and preparation method thereof

A low-permeability reservoir and composite flooding technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of unstable product performance, restricted performance, poor broad spectrum, etc., achieve good results and reduce use Concentration, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A composite oil displacement agent for enhanced oil recovery in low-permeability reservoirs, consisting of the following components in weight percent: polyacrylamide 12.5%, azobisisobutyronitrile 0.8%, styrene 18%, active polymer dispersant 5.5% %, ethanol 32% and water balance.

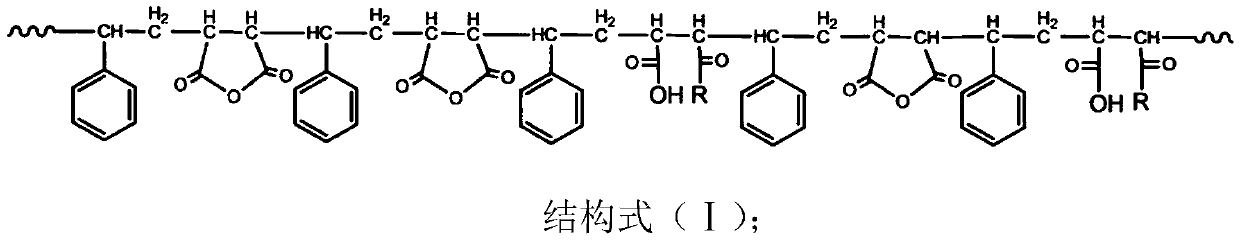

[0025] The structural formula (I) of the active polymer dispersant is:

[0026]

[0027]

[0028] Wherein, R is a β-hydroxyvinylsulfone sulfate active group.

[0029] The preparation method of the composite oil displacement agent for the enhanced recovery of the low permeability reservoir comprises the following steps:

[0030] Step 1, dissolving styrene in ethanol and stirring evenly to obtain solution A;

[0031] Step 2, dissolving azobisisobutyronitrile in 12 times of water to obtain solution B;

[0032] Step 3, dissolving polyacrylamide and active polymer dispersant in the remaining water to obtain solution C;

[0033] Step 4: Heat the container containing solution C in a water b...

Embodiment 2

[0035] A composite oil displacement agent for enhanced oil recovery in low-permeability reservoirs, consisting of the following components in weight percent: polyacrylamide 15%, azobisisobutyronitrile 0.5%, styrene 22%, active polymer dispersant 3 %, ethanol 35% and water balance.

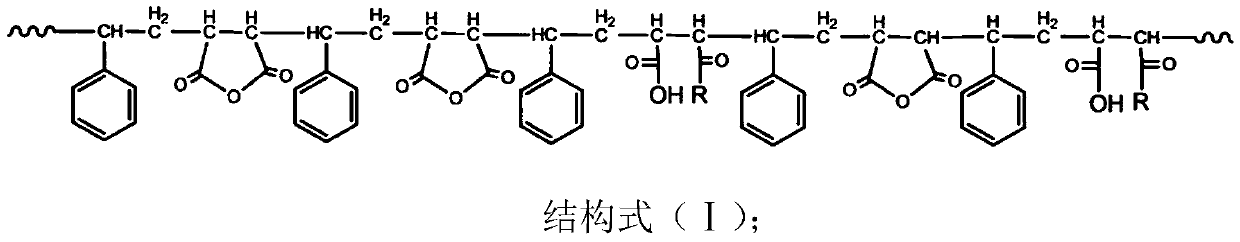

[0036] The structural formula (I) of the active polymer dispersant is:

[0037]

[0038] Wherein, R is a s-triazine active group.

[0039] The preparation method of the composite oil displacement agent for the enhanced recovery of the low permeability reservoir comprises the following steps:

[0040] Step 1, dissolving styrene in ethanol and stirring evenly to obtain solution A;

[0041] Step 2, dissolving azobisisobutyronitrile in 15 times of water to obtain solution B;

[0042] Step 3, dissolving polyacrylamide and active polymer dispersant in the remaining water to obtain solution C;

[0043] Step 4: Heat the container containing solution C in a water bath at 70°C until the temperature is...

Embodiment 3

[0045] A composite oil displacement agent for enhanced oil recovery in low-permeability reservoirs, consisting of the following ingredients in weight percent: 8% polyacrylamide, 1% azobisisobutyronitrile, 15% styrene, and 6% active polymer dispersant %, ethanol 25% and water balance.

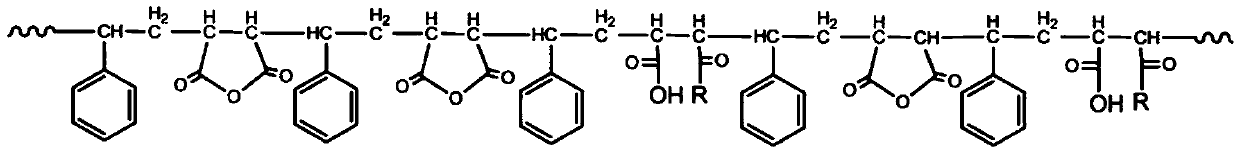

[0046] The structural formula (I) of the active polymer dispersant is:

[0047]

[0048] Wherein, R is an acrylamide active group.

[0049] The preparation method of the composite oil displacement agent for the enhanced recovery of the low permeability reservoir comprises the following steps:

[0050] Step 1, dissolving styrene in ethanol and stirring evenly to obtain solution A;

[0051] Step 2, dissolving azobisisobutyronitrile in 8 times of water to obtain solution B;

[0052] Step 3, dissolving polyacrylamide and active polymer dispersant in the remaining water to obtain solution C;

[0053] Step 4: Heat the container containing solution C in a water bath at 75°C until the temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Salinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com