Multi-spiral electrostatic spinning device

An electrospinning and multi-helix technology, applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of single needle blockage, difficulty in cleaning, low production efficiency of single needle electrospinning, etc., to achieve Avoid easy clogging, avoid easy volatilization, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

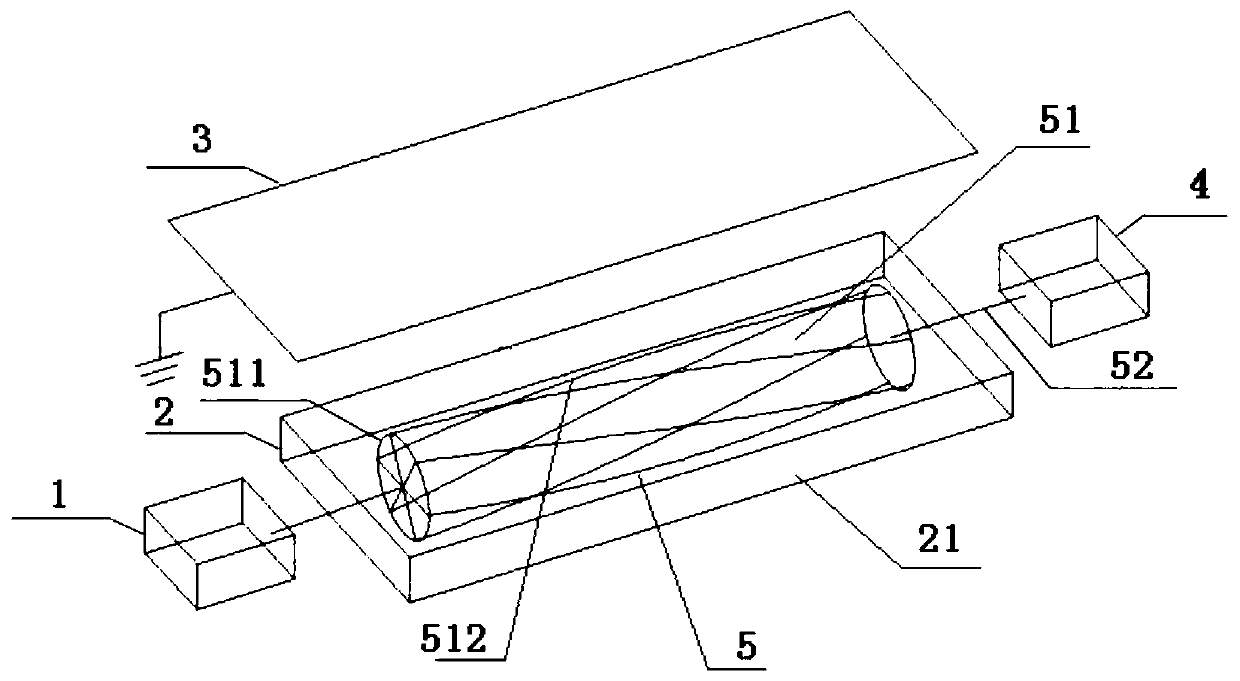

[0022] Combine below Figure 1-3 For further clarification:

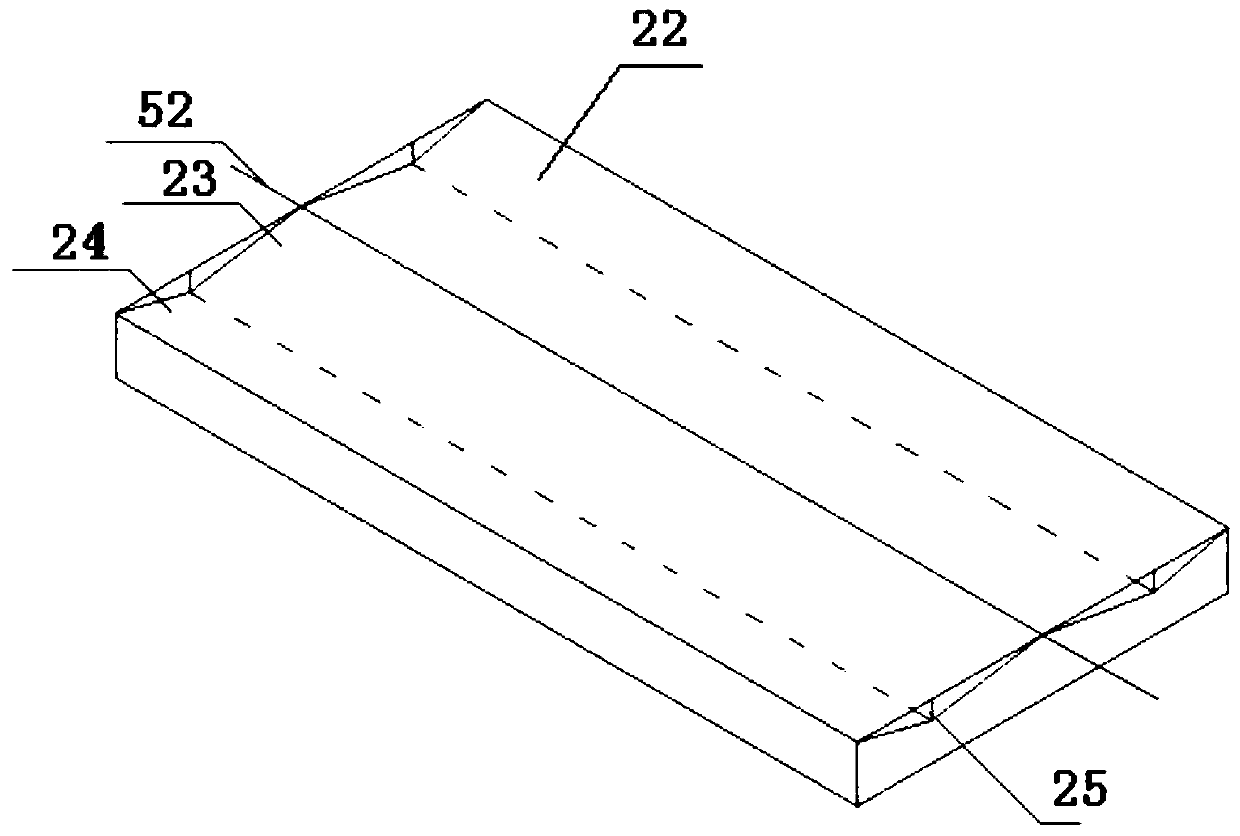

[0023] A multi-helix electrospinning device, comprising a liquid storage tank 2, a multi-helix spinning system 5 is placed in the center of the liquid storage tank 2, a fiber receiving plate 3 is arranged above the multi-helix spinning system 5, and a multi-helix spinning system 5 is arranged. The two ends of the silk system are respectively connected with a nozzle rotating system 4 and a high-voltage electrostatic generator 1; the multi-helix spinning system includes a multi-helix nozzle 5 and a central shaft 52 installed in the center of the liquid storage tank 2, and the two ends of the central shaft 52 After extending out of the liquid storage tank 2, it is respectively connected with the nozzle rotation system 4 and the high-voltage electrostatic generator 1; the central axis 52 is provided with a multi-helix nozzle 51, and the multi-helix nozzle 51 is composed of rings 511 on both sides and a spiral metal wir...

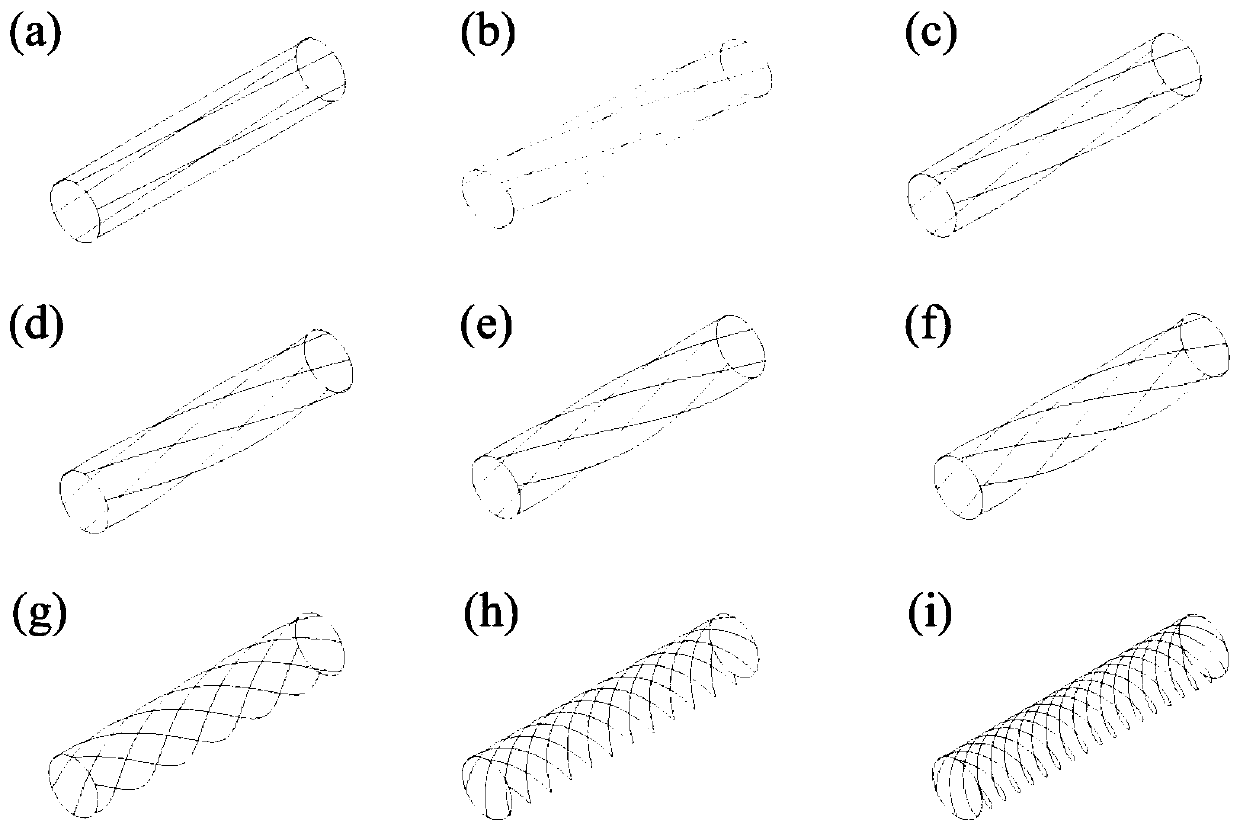

Embodiment 2-4

[0034] Others are all the same as the embodiment, except that the helix angle is different, and the specific data are as follows:

[0035]

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com