PPVC modular building structure system and assembly method thereof

A technology of building structure and assembly method, which is applied in the direction of building components, building structure, construction, etc., can solve the problem of tensile resistance, pull resistance, shear resistance, pull resistance, and bending resistance, which affect a wide range of PPVC modular buildings. The use and connection points do not take into account the seismic performance of the structure, etc., to achieve the effect of shortening the construction period, good application prospects, and increasing the tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

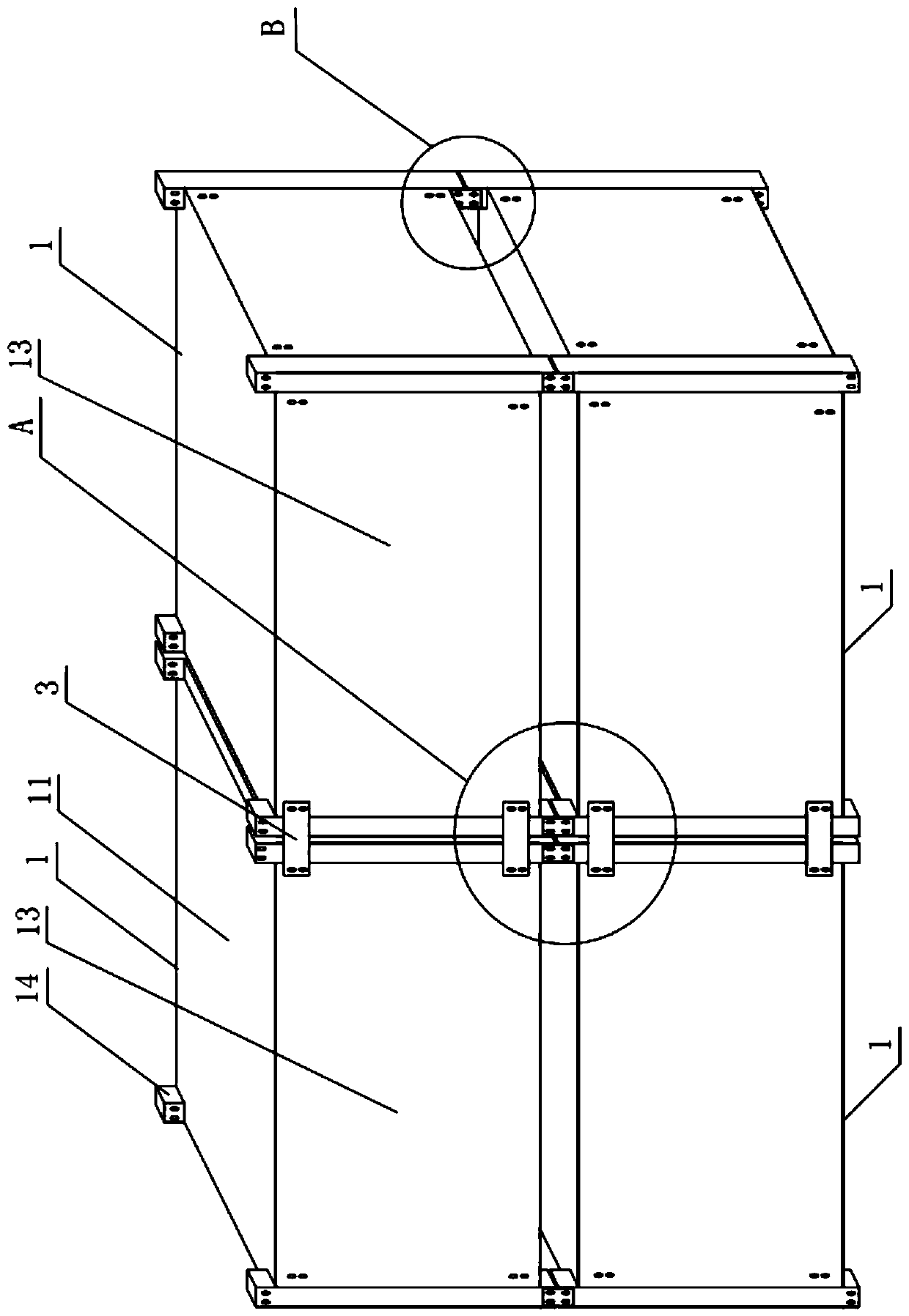

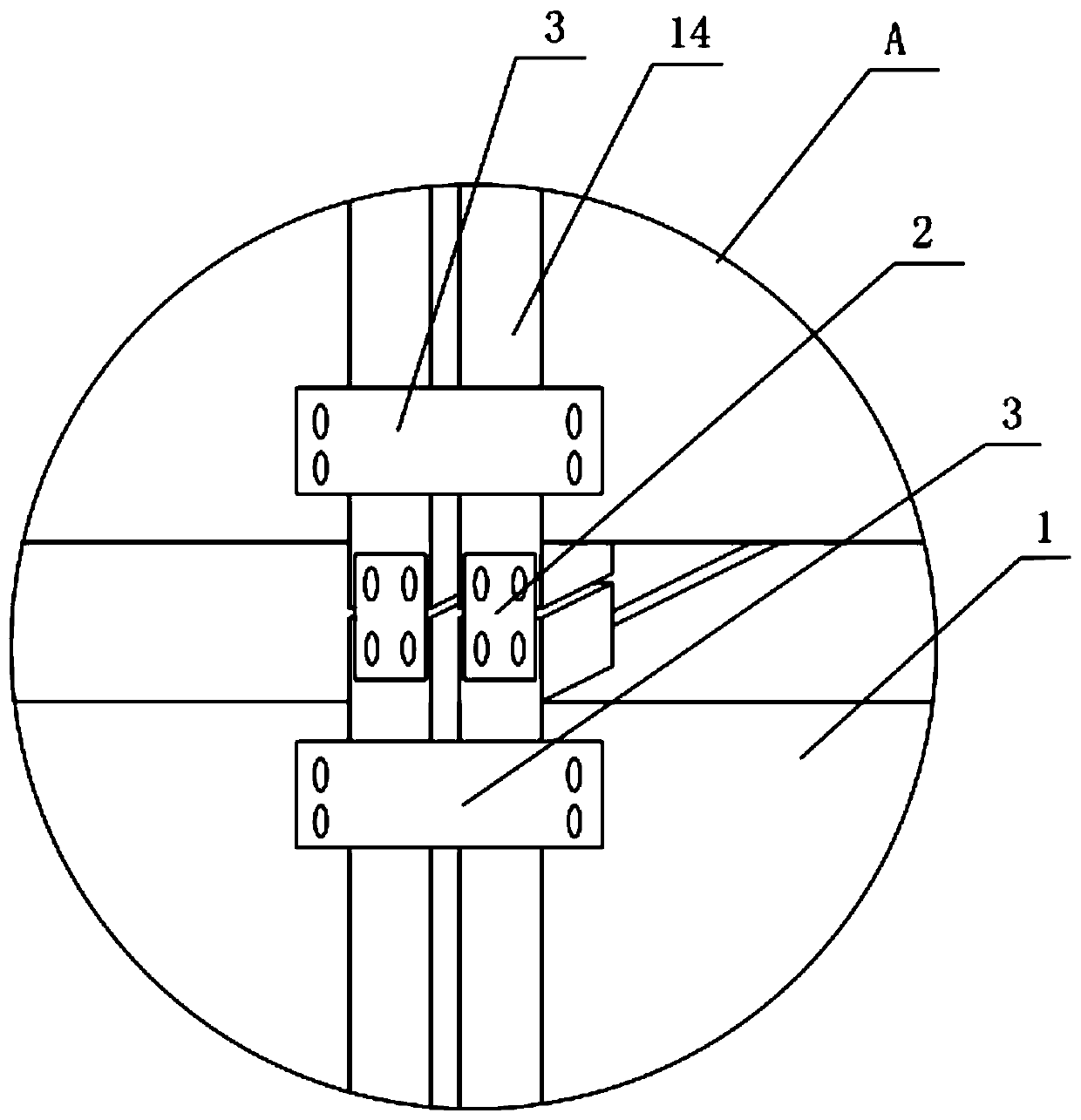

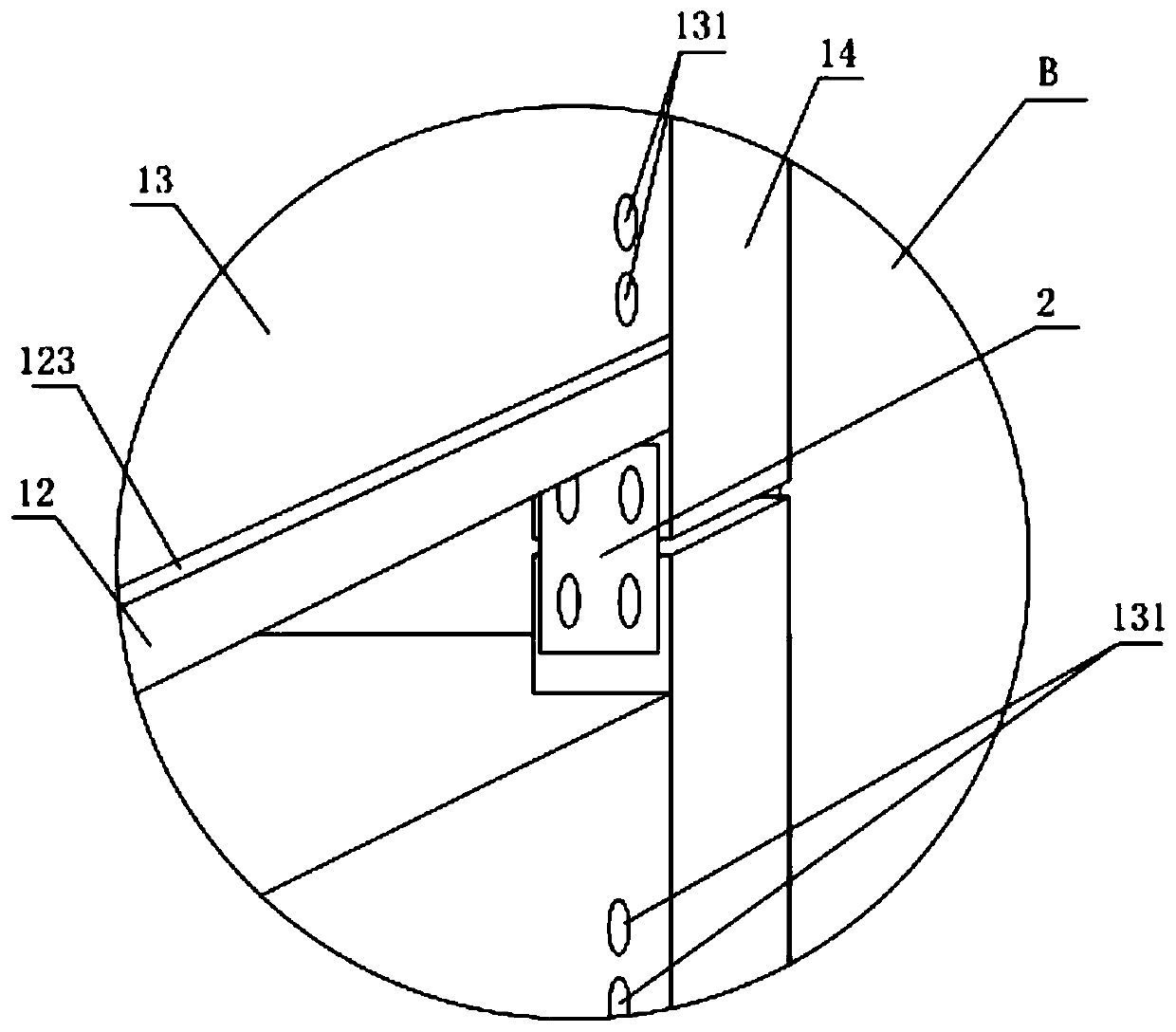

[0044] Such as Figure 1 to Figure 8 As shown, a PPVC modular building structure system according to the present invention, the structure system is composed of several identical modules 1, each module 1 includes an upper floor 11, a lower floor 12, several wall panels 13 and several columns 14. The wallboards 13 are arranged at intervals, and columns 14 are arranged between the adjacent wallboards 13, and the sides of the wallboards 13 are fixedly connected to the side walls of the columns 14 (it can be bolted or tenoned) connection), the upper floor 11 covers the top of the module 1, and the lower floor 12 covers the bottom of the module 1, and the lower floor 12 includes a prefabricated slab 121 and a cast-in-place slab 122 that cooperate with each other, and the prefabricated slab 121 and the cast-in-place slab 122 are interlocking tooth-like structures, and the areas of the prefabricated slab 121 and the cast-in-place slab 122 can each account for half; The all-cast-in-pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com