A device and method for analyzing the mechanical properties of hydrate sediments based on low-field NMR

A technology of hydrate deposits and mechanical properties, applied in the direction of analysis, analysis materials, measurement devices, etc. by means of nuclear magnetic resonance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026]Embodiment 1. This embodiment proposes a device for analyzing the mechanical properties of hydrate sediments based on low-field nuclear magnetism.

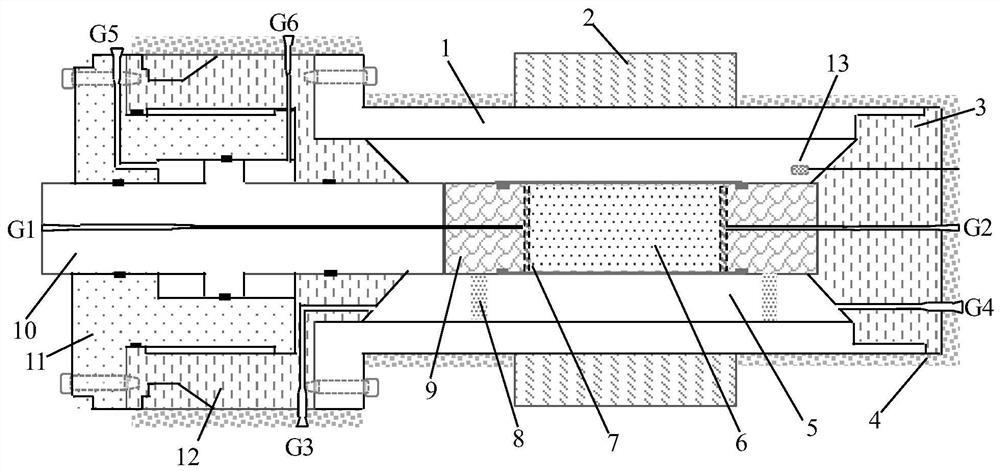

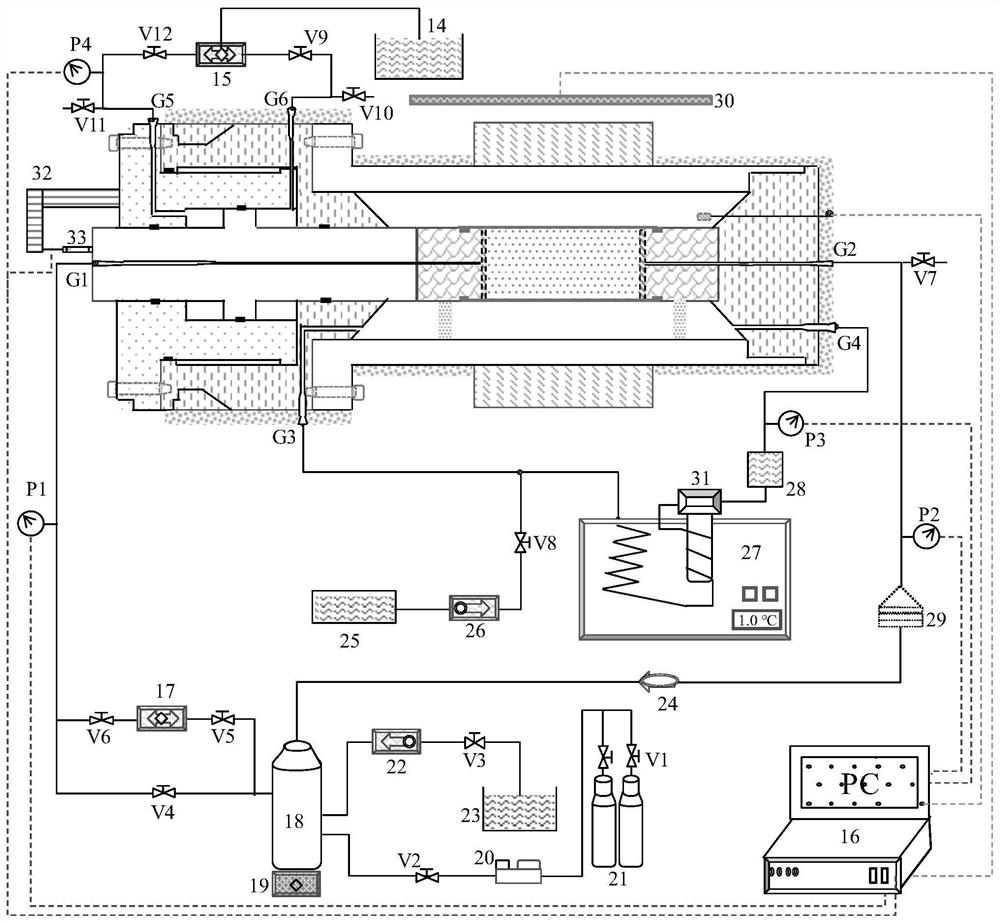

[0027]referencefigure 1 andfigure 2 , Including: micro reactor, as well as pore pressure control module, confining pressure control module, axial loading control module and data acquisition module.

[0028]The reactor is directly installed on the low-field nuclear magnetic resonance analyzer to realize the analysis of the pore structure of the hydrate sediment. The whole reactor is a cylindrical structure, made of non-nuclear magnetic signal material such as carbon fiber, including the reactor body 1, the radio frequency coil 2, the upper end cover of the reactor 3, the lower end cover of the reactor 4, the axial pressure loading plunger 10, and the axial pressure Load the reaction force frame 11, the lateral support ring 8, the sample height adjustment pad 9 and the rubber sleeve loaded with sediment.

[0029]The radio frequency coil 2 is...

Embodiment 2

[0037]In the second embodiment, this embodiment proposes a method for qualitatively / quantitatively diagnosing the damage type of hydrate deposits based on the results of nuclear magnetic resonance detection.

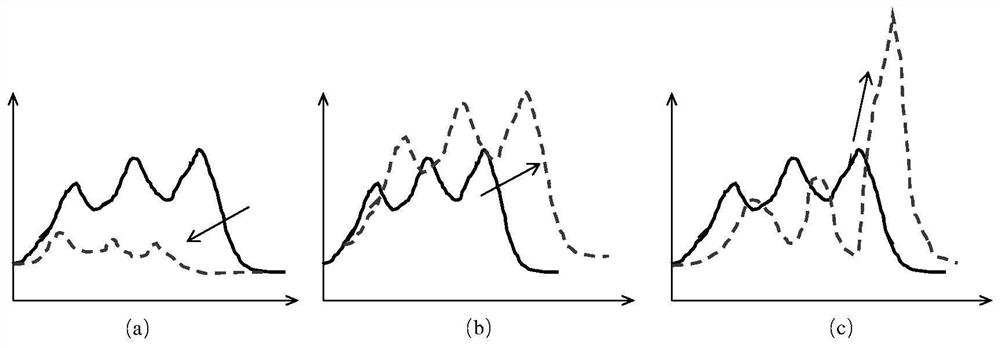

[0038]The applicant's research found that under the conditions of triaxial constant-rate axial compression shear or creep compression shear, the basic failure modes of the sediments can be divided into three basic modes: compaction, compression expansion, and fracturing. The main idea for low-field nuclear magnetic resonance to obtain the internal pore structure characteristics of sediments is: low-field nuclear magnetic resonance can obtain the relationship curve between nuclear magnetic resonance intensity and transverse relaxation time, and the transverse relaxation time obtained by different pore types under low-field nuclear magnetic resonance conditions The relaxation time is different, and the positions of the peaks formed on the relaxation spectrum of pores of different s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com