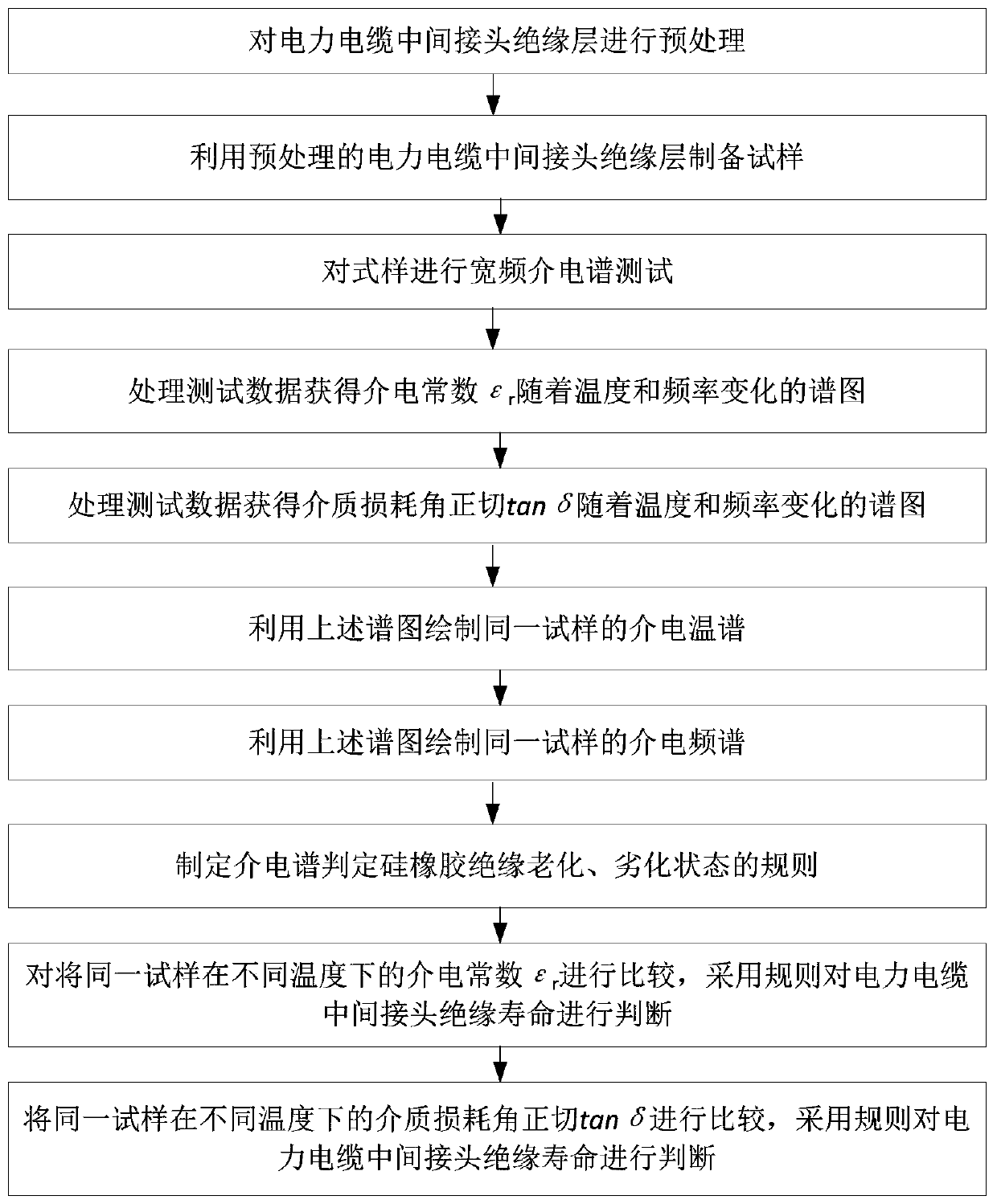

Power cable intermediate joint insulation detection method based on dielectric spectrum method

A technology for power cables and intermediate joints is applied in the field of insulation testing of intermediate joints of power cables, which can solve the problems of accelerated insulation aging, deterioration, performance failure, interface structure defects, etc., to achieve accurate test results, ensure safe and stable operation, and reduce power grid accidents. the effect of risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Using the method of the present invention to evaluate the insulation life of the prefabricated silicone rubber power cable intermediate joints in service for 5 years is as follows.

[0078] Step 1001, take the insulation layer of the prefabricated silicone rubber cable intermediate joint that has not been in service and has been in service for 5 years, and cut it into test pieces with a thickness of 1mm, wipe the surface clean and dry, and set aside.

[0079] Step 1002, cutting the tested test piece into a circular test piece with a diameter of 30 mm and a thickness of 1 mm as a sample.

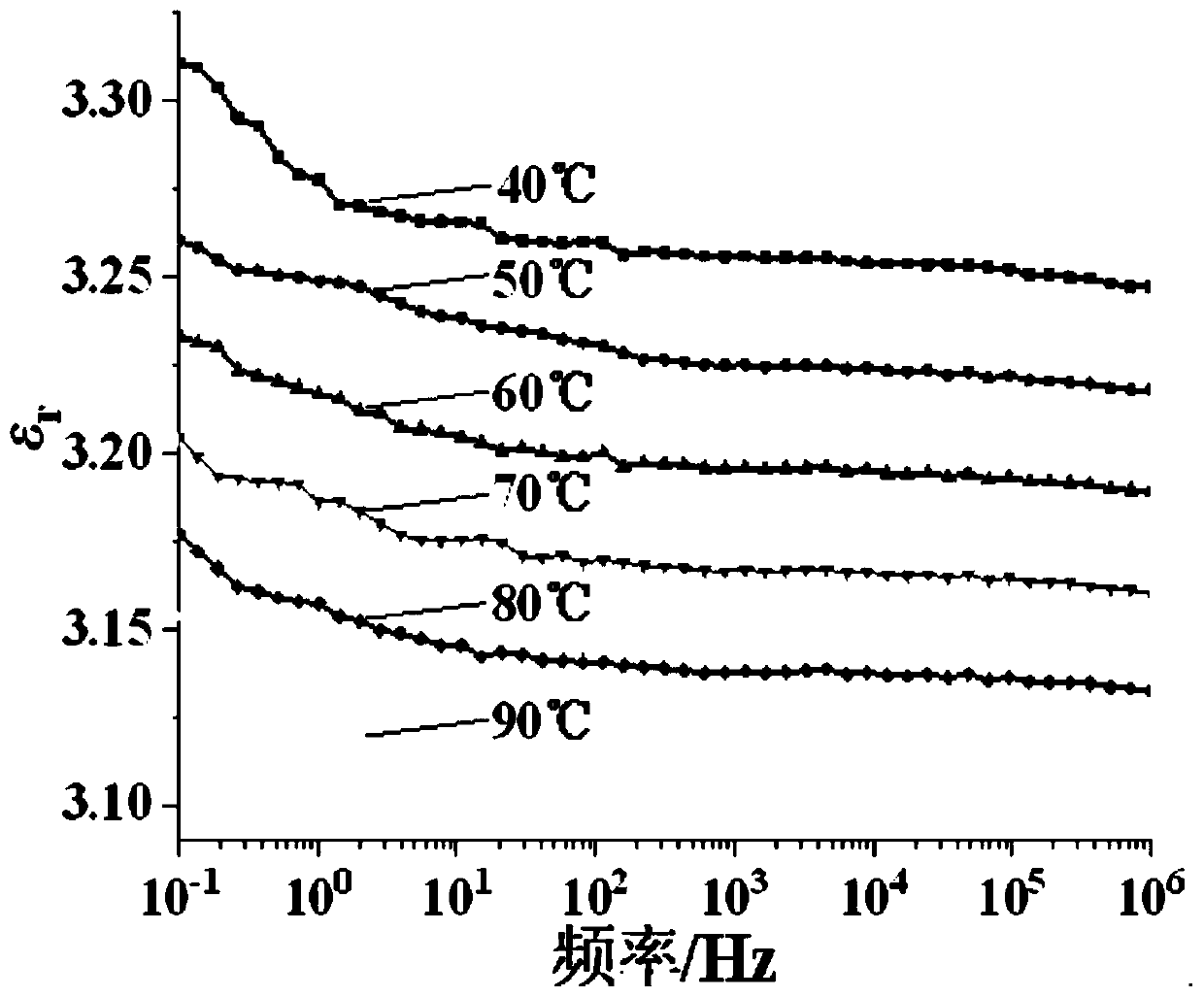

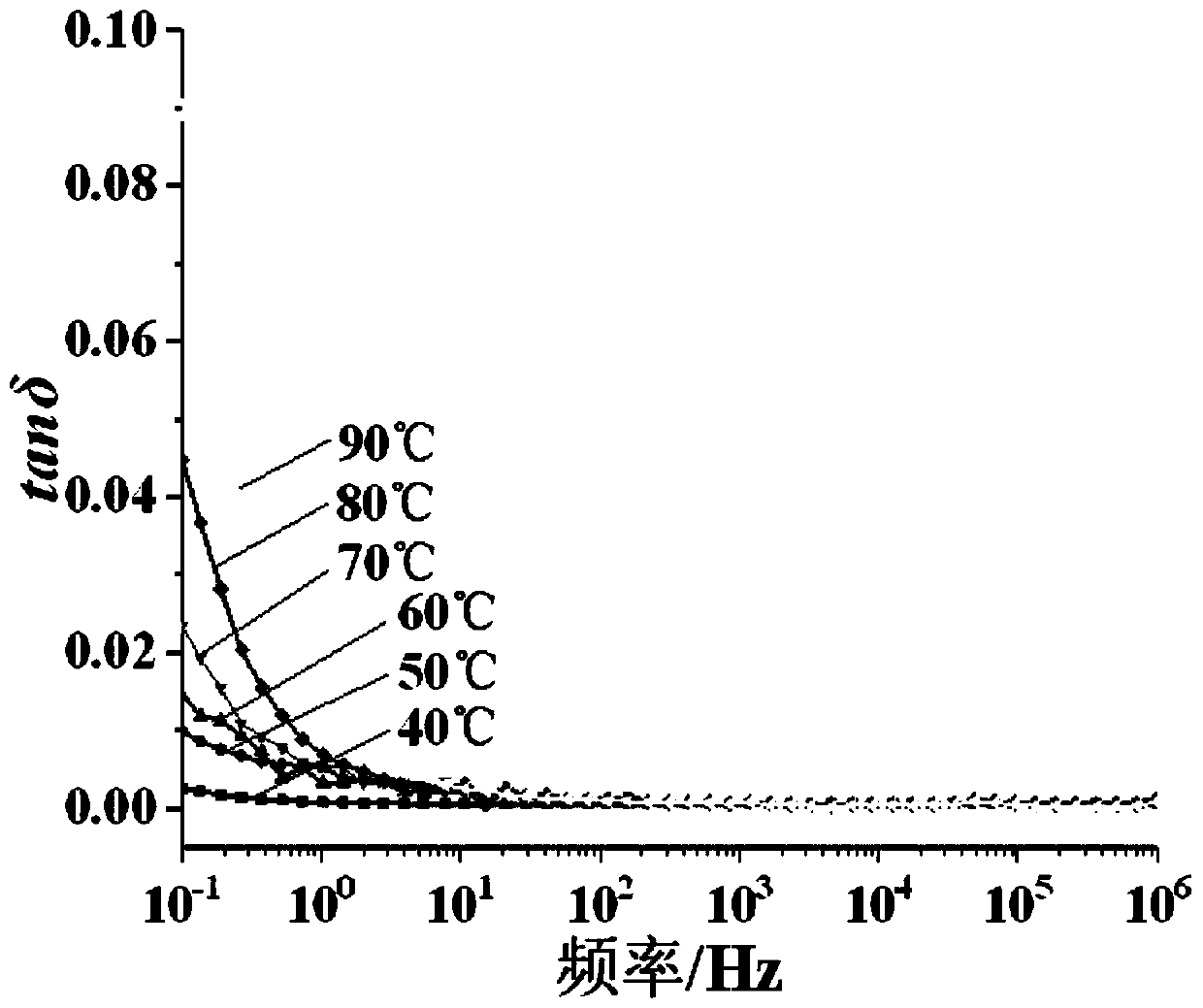

[0080] Step 1003, using the Novocontrol Concept 80 test system, the spectrum and temperature spectrum test of the broadband dielectric spectrum is carried out on the sample, and the test frequency range is 10 -1 ~10 6 Hz, and the temperature is 40°C to 90°C.

[0081] Step 1004, use origin to process the tested dielectric constant data, and draw the relative dielectric constant ε of t...

Embodiment 2

[0089] Using the method of the present invention to evaluate the insulation life of the prefabricated silicone rubber power cable intermediate joints in service for 8 years is as follows.

[0090] Step 1001, take the insulation layer of the prefabricated silicone rubber cable intermediate joint that has been in service for 8 years, cut it into test pieces with a thickness of 1mm, wipe the surface clean and dry, and set aside.

[0091] Step 1002, cutting the tested test piece into a circular test piece with a diameter of 30 mm and a thickness of 1 mm as a sample.

[0092] Step 1003, using the Novocontrol Concept 80 test system, the spectrum and temperature spectrum test of the broadband dielectric spectrum is carried out on the sample, and the test frequency range is 10 -1 ~10 6 Hz, and the temperature is 40°C to 90°C.

[0093] Step 1004, use origin to process the data of the tested dielectric constant, and draw the relative dielectric constant ε of the sample that has been i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com