Method and device for suppressing light source intensity noise by using proportional compensation of electro-optical modulator

An electro-optical modulator and light source intensity technology, which is applied in the exploration of optical devices and other directions, can solve the problems of low response bandwidth, limitation, and limited noise suppression effect of low-frequency intensity noise of acousto-optic modulators, and achieves easy application and implementation, low cost, and realization of Effects of Intensity Noise Suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

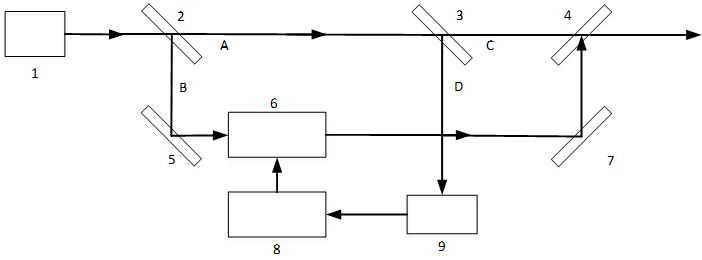

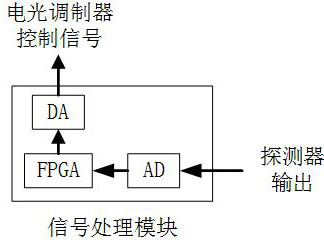

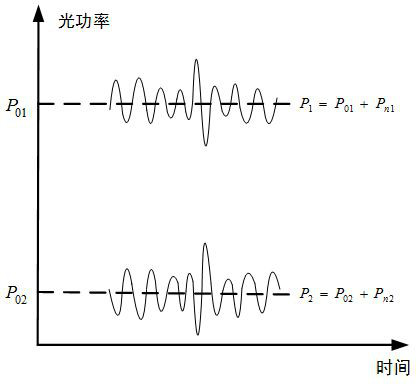

[0025] refer to figure 1 , a device for suppressing light source intensity noise using electro-optical modulator proportional compensation, comprising a light source 1, a first beam splitter 2, a second beam splitter 3, a beam combiner 4, a first reflector 5, an electro-optic modulator 6, a second reflector Mirror 7 , signal processing module 8 and photodetector 9 . The light emitted by the light source 1 is divided into a beam A and a beam B by the first beam splitter. The beam A is stronger than the beam B. The beam B enters the electro-optic modulator 6 through the first reflector 5, and the beam A is divided into beams by the second beam splitter 3. C and D, the light beam C is stronger than the light beam D, the light beam D is connected to the photodetector 9, the electrical signal after photoelectric conversion is connected to the signal processing module 8, and the signal processing module 8 outputs the electrical signal to control the electro-optical modulator 6, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com