Method and device for restraining light source intensity noise through electro-optical modulator proportional compensation

A technology of electro-optic modulator and light source intensity, which is applied in the direction of optical device exploration, etc., can solve the problems of limitation, low response bandwidth of acousto-optic modulator, and limited suppression effect of low-frequency band intensity noise, and achieve low cost, easy application and implementation, and realization Effect of Intensity Noise Suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

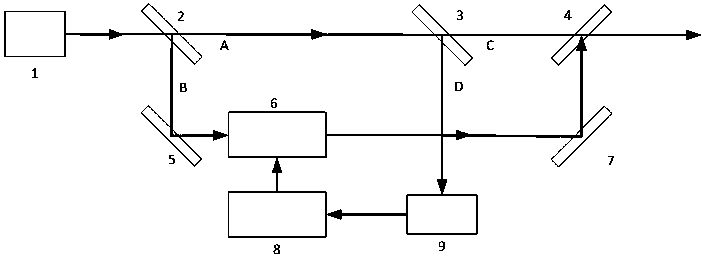

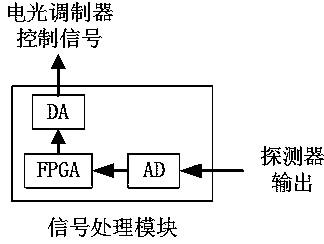

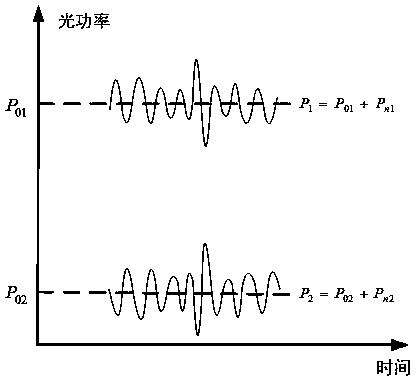

[0025] refer to figure 1 , a device that uses electro-optic modulator proportional compensation to suppress light source intensity noise, comprising a light source 1, a first beam splitter 2, a second beam splitter 3, a beam combiner 4, a first reflector 5, an electro-optic modulator 6, a second reflector Mirror 7, signal processing module 8 and photodetector 9. The light emitted by the light source 1 is divided into beam A and beam B by the first beam splitter, beam A is stronger than beam B, beam B enters the electro-optic modulator 6 through the first reflector 5, and beam A is divided into beams by the second beam splitter 3 C and D, the light beam C is stronger than the light beam D, the light beam D is connected to the photodetector 9, and the electrical signal after photoelectric conversion is connected to the signal processing module 8, and the signal processing module 8 outputs an electric signal to control the electro-optic modulator 6, and the electro-optic modulato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com