Equipment for automatically picking leaves in advance for preparing high-protein dairy cow feed from hybrid broussonetia papyrifera

A dairy cow feed and high-protein technology, which is applied to harvesting machines, agricultural machinery and tools, and applications, can solve the problems of affecting the economic benefits of tree leaves, high labor intensity, and low picking efficiency, and achieves ingenious structure and high degree of automation , Improve the effect of picking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

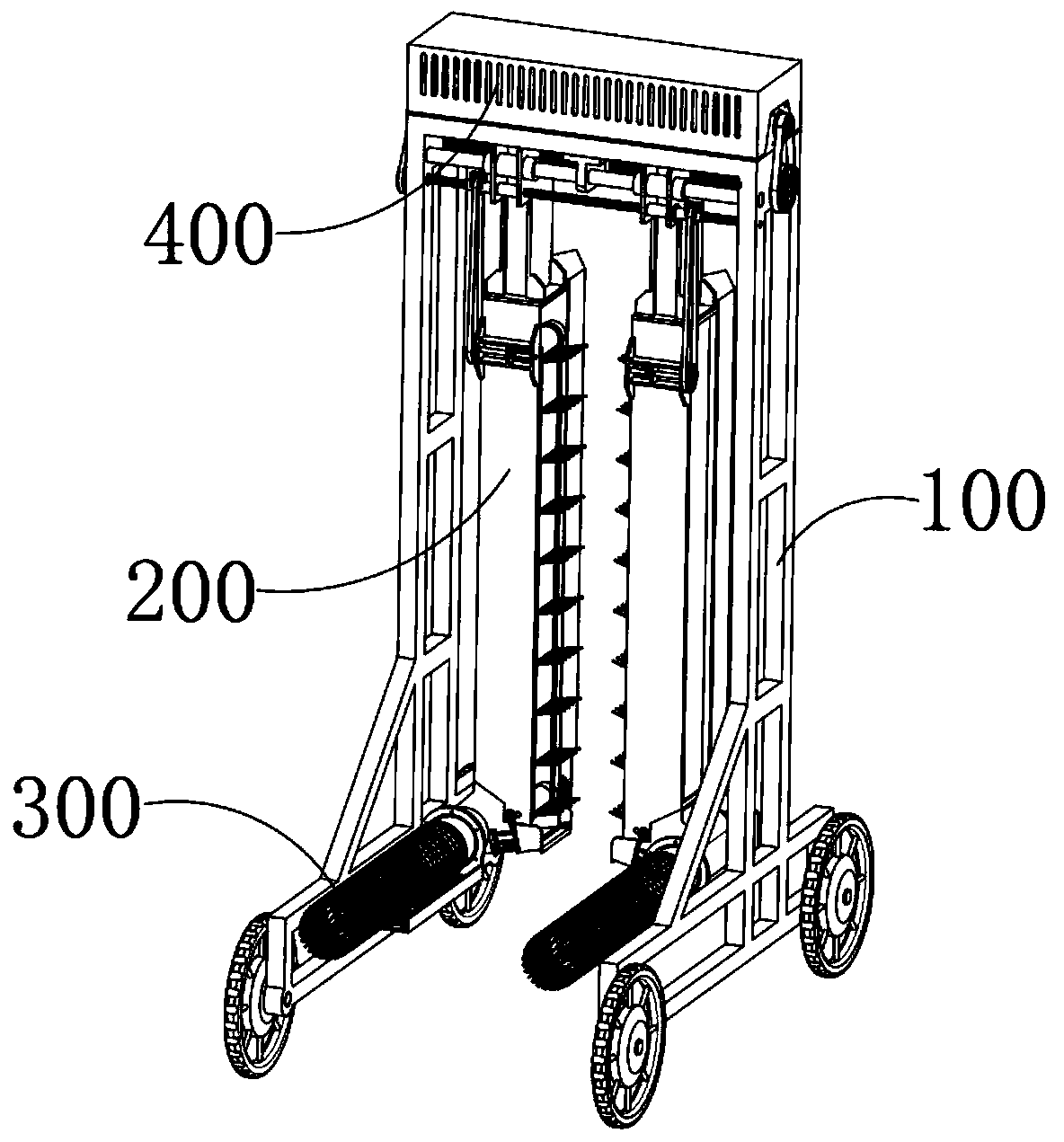

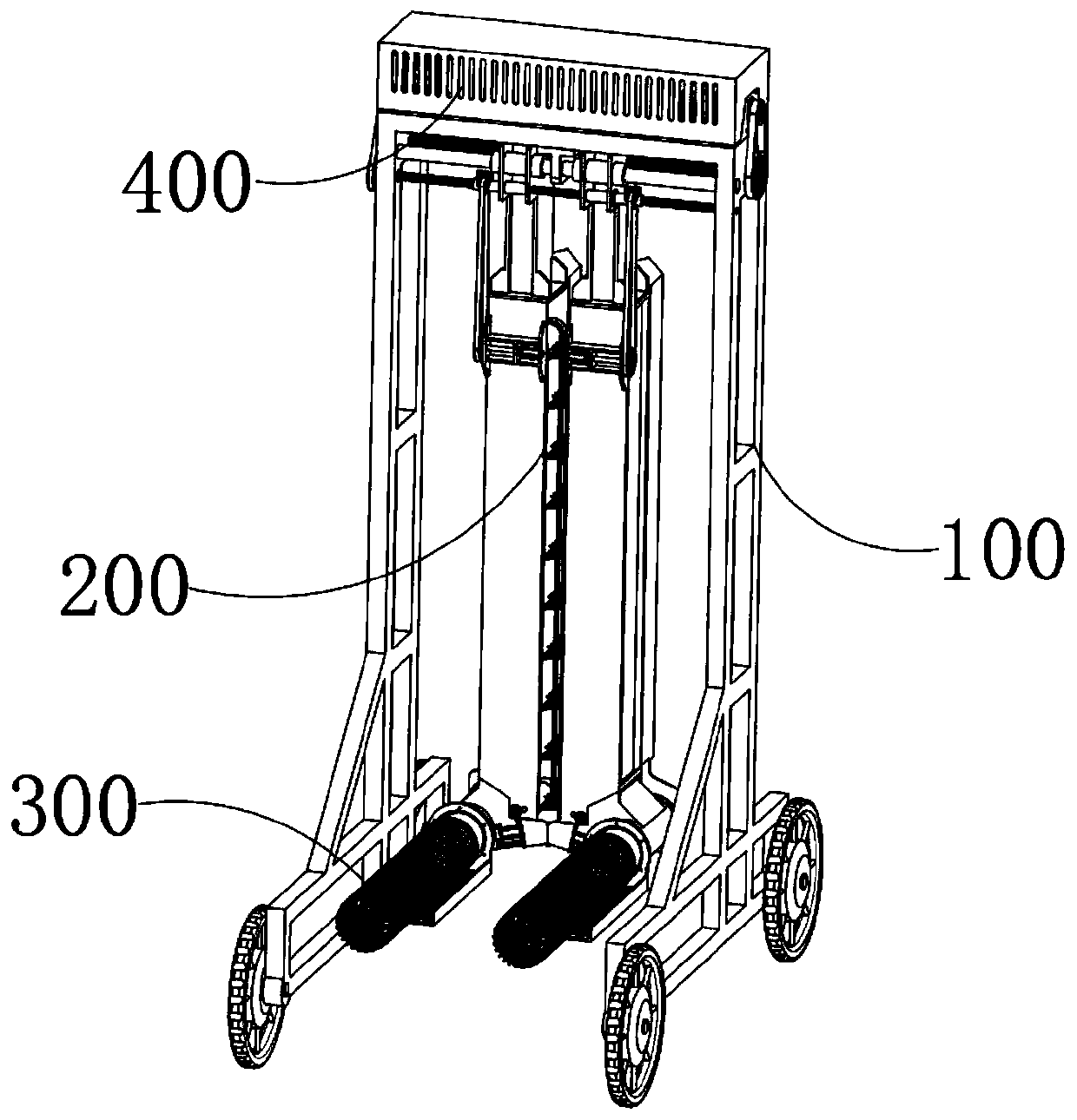

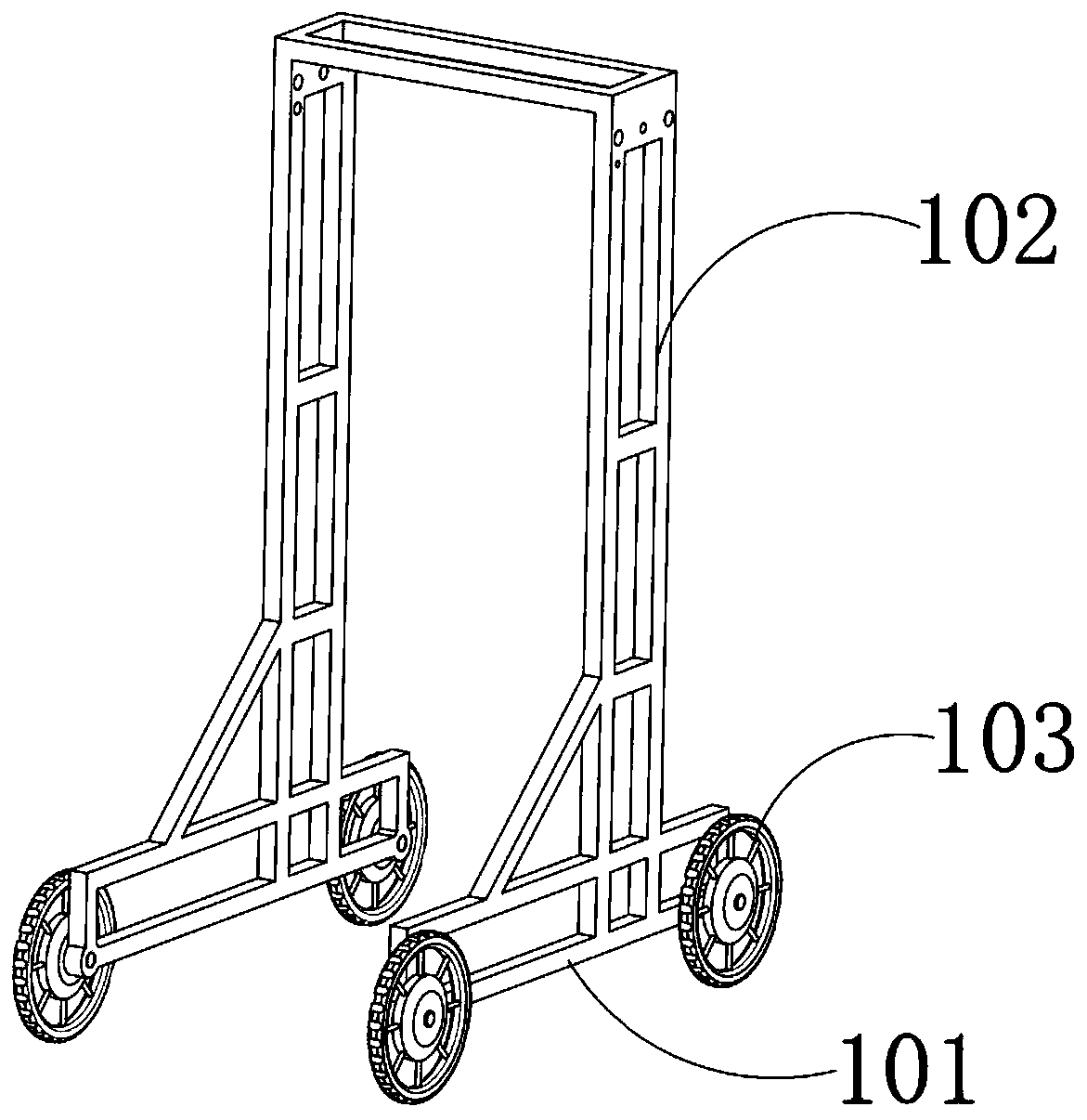

[0051] see Figure 1-19 , the equipment for automatically picking leaves in advance by hybridizing the tree to produce high-protein dairy cow feed, which includes a mounting frame 100, a picking device 200, a collecting device 300 and a power drive device 400, and the picking device 200 is used for picking the leaves of the tree, collecting The device 300 is used to collect the leaves picked by the picking device 200. The power drive device 400 can transmit power to the picking device 200 and drive the picking device 200 to operate normally. The picking device 200 can transmit power to the collecting device 300 And drive collection device 300 normal operation, described installation frame 100 comprises two rectangular horizontal frames 101 that are arranged at intervals, two rectangular vertical frames 102 that are arranged at intervals, vertical frame 102 corresponds to horizontal frame 101 one by one and its lower end Fixedly connected to the middle position of the horizonta...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap