Catalytic ozonation catalyst for treating wastewater, and preparation method thereof

A technology for ozone catalytic oxidation and wastewater treatment, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc. Catalytic efficiency and other issues to achieve the effect of enhancing adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

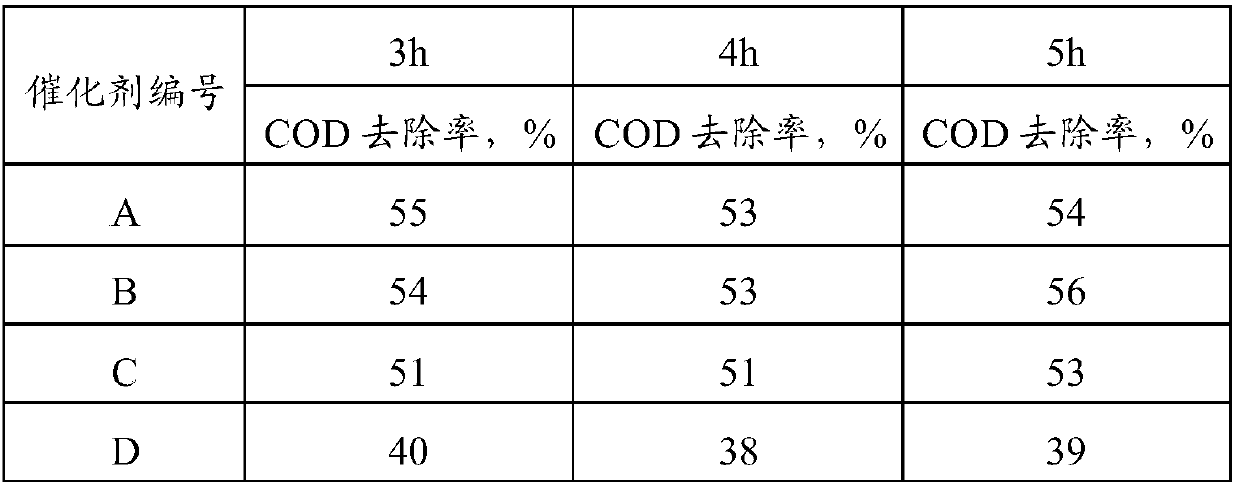

Examples

Embodiment 1

[0038] The first step of impregnation: put the columnar activated carbon carrier with a diameter of 3mm-4mm into the aqueous solution of ethylene glycol, then stir evenly, impregnate for 3 hours, and obtain the intermediate product after filtration. Here, the amount of ethylene glycol added is 0.1 times the sum of the moles of the active components used in the second step of impregnation.

[0039] The second step of impregnation: put the intermediate product impregnated in the first step into a mixed solution (active component precursor solution) composed of Mn metal elements and Cu metal elements with a mass ratio of 1:1, and according to 1kg activated carbon can load The ratio of 1g of Mn metal element and 1g of Cu metal element is used to mix and impregnate the activated carbon carrier and the mixed solution for 3h, and then filter to obtain a pre-product. Here, the manganese precursor used in the second immersion solution is commercially available 50% manganese nitrate sol...

Embodiment 2

[0042] The first step of impregnation: put the columnar activated carbon carrier with a diameter of 3mm-4mm into the aqueous solution of ethylene glycol, then stir evenly and impregnate for 4 hours to obtain an intermediate product. Here, the amount of ethylene glycol added is 10 times the sum of the moles of the active components used in the second step of impregnation.

[0043] The second step of impregnation: put the intermediate product impregnated in the first step into a mixed solution (active component solution) composed of Mn metal elements and Cu metal elements with a mass ratio of 10:1, and according to the fact that 1kg of activated carbon can load 100g of Mn The ratio of the metal element and 10g Cu metal element is used to mix and impregnate the activated carbon carrier and the mixed solution for 24h, and then filter to obtain the pre-product. Here, the manganese precursor used in the second immersion solution is commercially available 50% manganese nitrate soluti...

Embodiment 3

[0046] The first step of impregnation: put the columnar activated carbon carrier with a diameter of 3mm-4mm into the aqueous solution of ethylene glycol, then stir evenly, impregnate for 4 hours, and obtain the intermediate product after filtration. Here, the amount of ethylene glycol added is twice the sum of the moles of the active components used in the second step of impregnation.

[0047] The second step of impregnation: put the intermediate product impregnated in the first step into the mixed solution (active component solution) composed of Mn metal element and Cu metal element with a mass ratio of 5:1, and according to the fact that 1kg of activated carbon can load 50g of Mn The ratio of the metal element and 10g Cu metal element is used to mix and impregnate the activated carbon carrier and the mixed solution for 4h, and then filter to obtain a pre-product. Here, the manganese precursor used in the second immersion solution is commercially available 50% manganese nitra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com