A Real-time Pose Estimation Method for Seam Tracking System

A tracking system and attitude estimation technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of low precision and welding robots can't adapt to various welding conditions, so as to improve efficiency, high degree of automation, easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be further described in detail below with reference to the embodiments and accompanying drawings, but the embodiments of the present invention are not limited thereto.

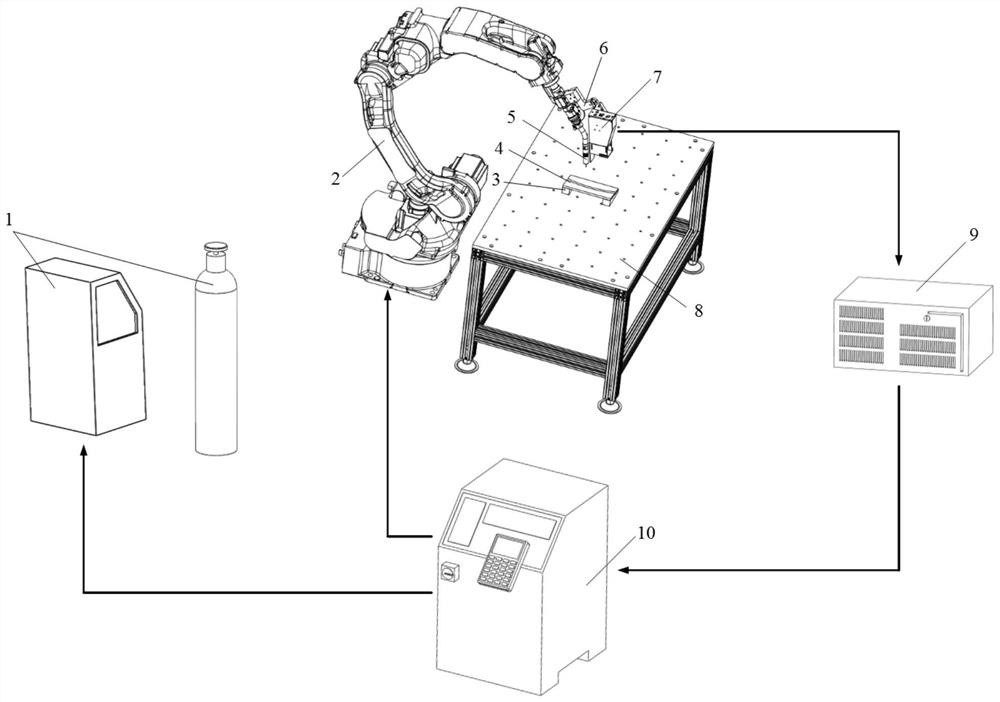

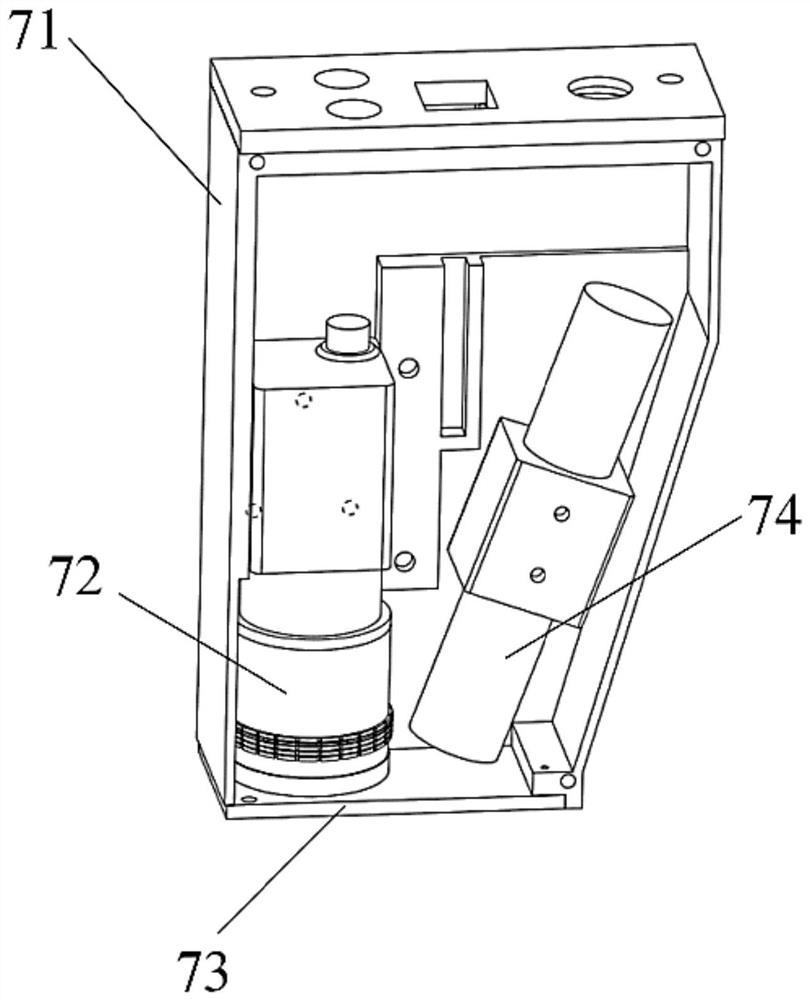

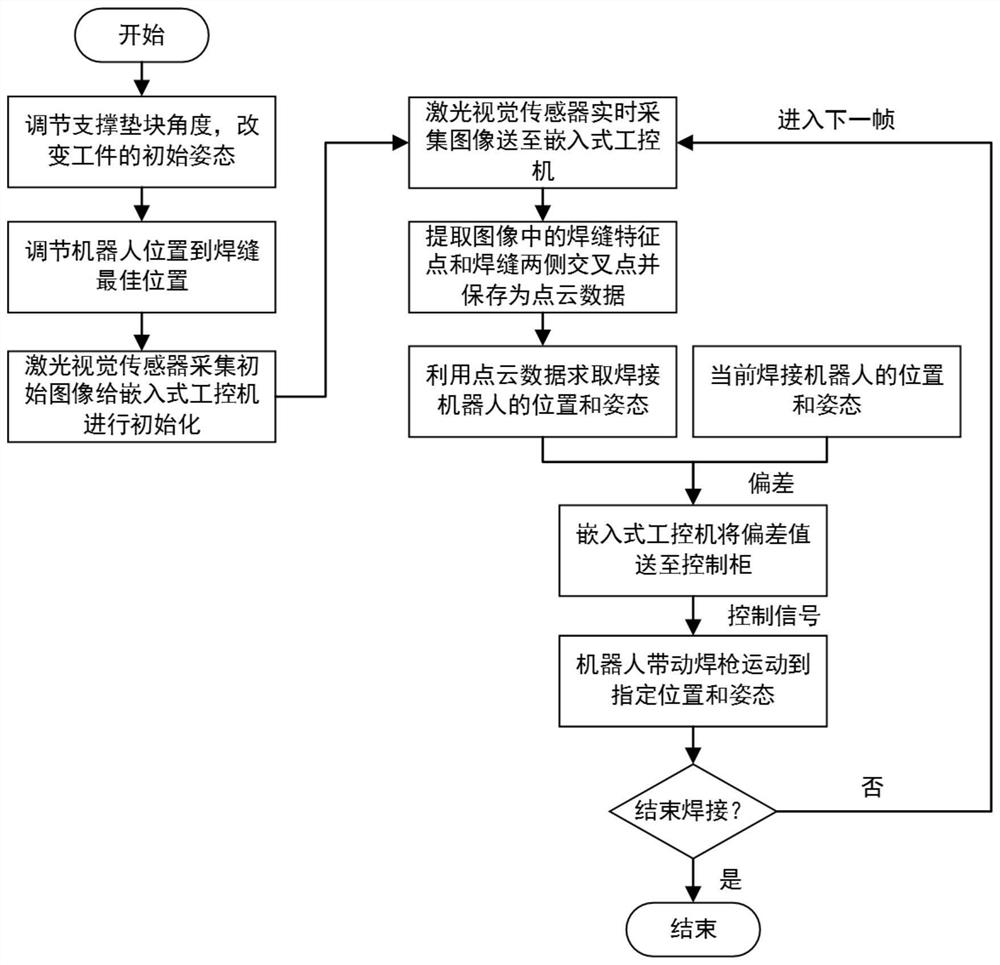

[0069] like figure 1 , figure 2Shown, a kind of real-time pose estimation method of seam tracking system, this method is based on the seam tracking system, and this system comprises welding robot 2, welding torch 5, laser vision sensor 7, laser vision sensor outer connector 6 (outer connector 6 is a bolt and nut connector, which connects and fixes the laser vision sensor 7 and the sensor housing 71), workbench 8, support pad 3, supporting welding equipment 1, embedded industrial computer 9, control cabinet 10 and workpiece 4; workpiece 4 Placed on the support block 3, the support block 3 is placed on the workbench 8, the inclination angle of the workpiece 4 can be adjusted by the support block 3, so that the workpiece 4 has different postures, and also makes the welding robo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com