Multifunctional laser marking machine

A laser marking machine and multi-functional technology, applied in the field of laser applications, can solve the problems of increasing user equipment costs, idle waste of equipment resources, etc., and achieve the effect of solving idle waste and reducing equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

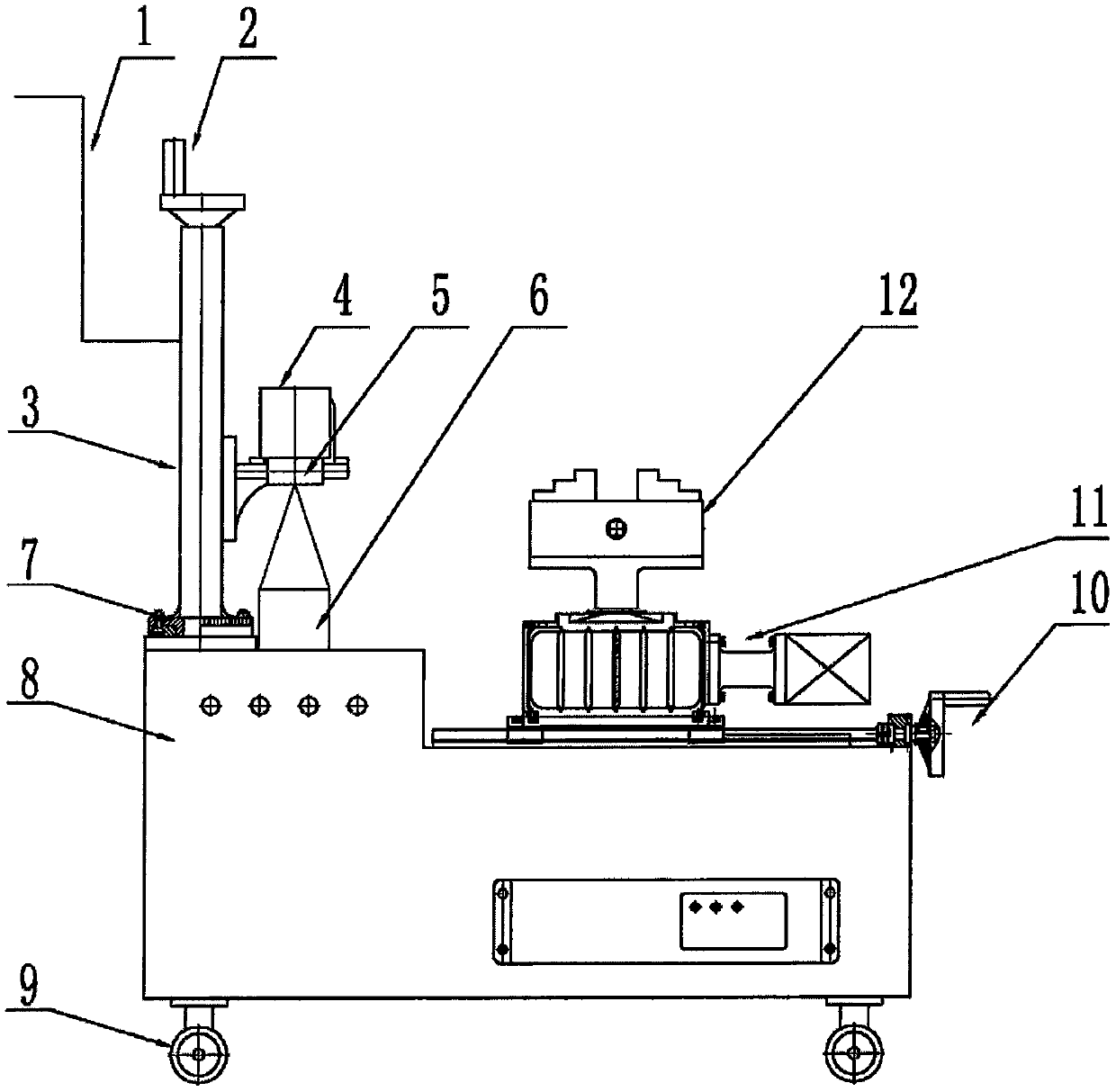

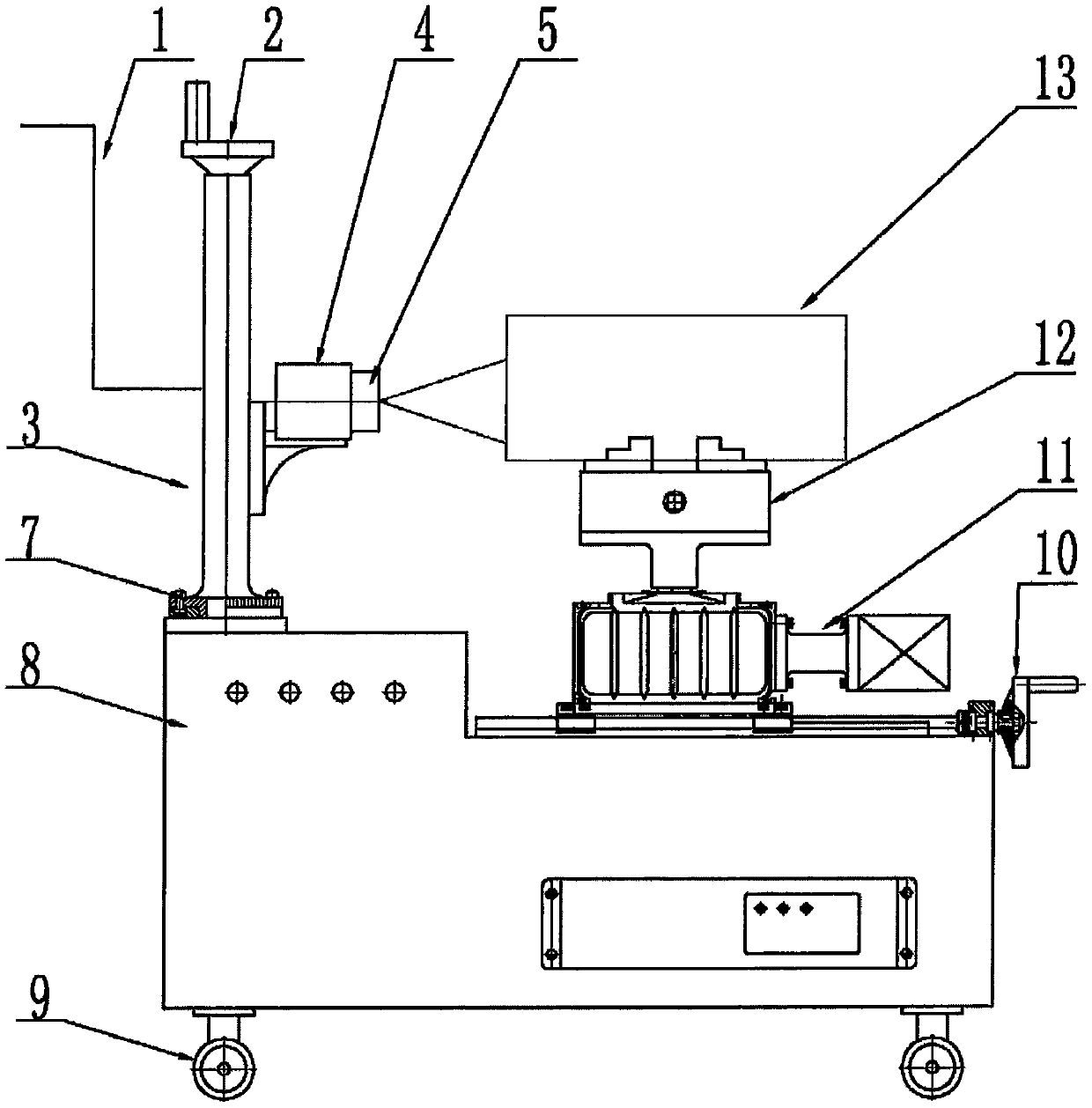

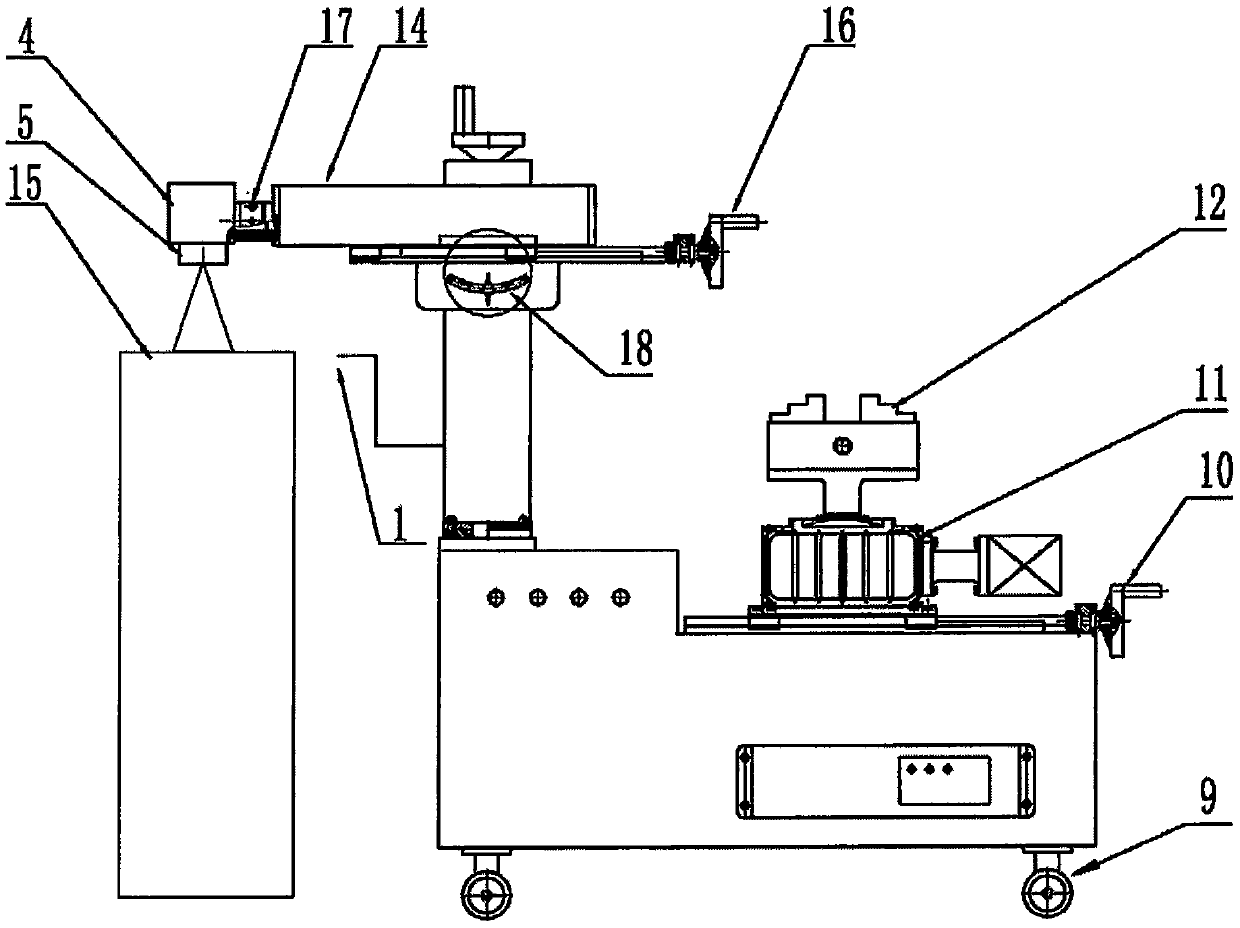

[0015] As a specific embodiment of the multifunctional laser marking machine, the multifunctional laser marking machine includes a column 3, a laser optical path component 14 installed on the column 3, and the column 3 is installed on the left side of the workbench 8 at the bottom. The transmission line 1 for the control of the middle position on the top 3 is externally connected to the computer control system, the laser optical path component 14 and the reader proximal end are equipped with a laser vibrating mirror 4 and a laser field mirror 5, and a column is designed at the connection between the column 3 and the lower workbench 8 The rotating mechanism 7; the galvanometer rotating mechanism 17 is designed at the connection between the vibrating mirror 4 and the laser optical path part 14; the laser optical path part 14 and the column 3 are connected by a mounting frame, and a rotating mechanism 18 is designed between the mounting frame and the column 3 to allow it Rotate on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com