Large component rotary welding mould

A technology of spin welding and large-scale components, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of workers wasting working hours, unable to weld components, and affecting processing efficiency, so as to avoid wasting working hours and facilitate operation , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

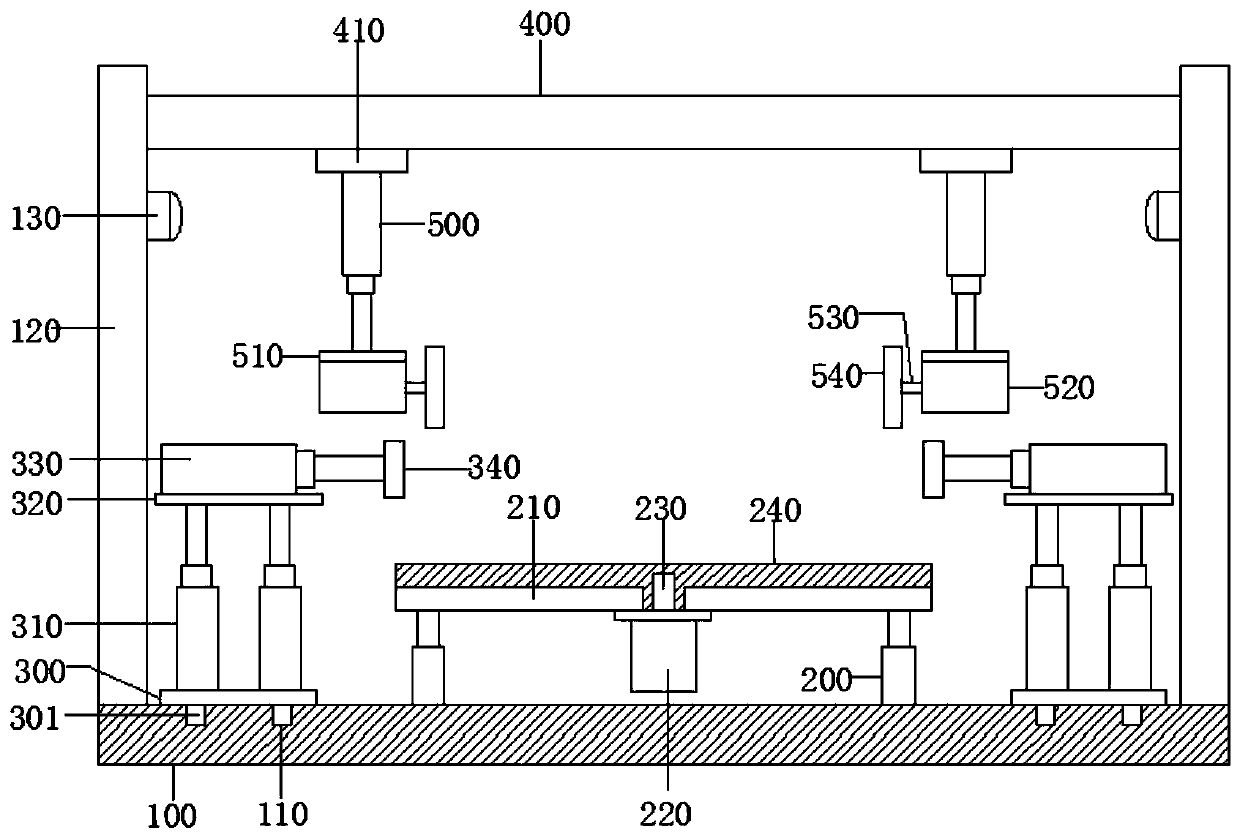

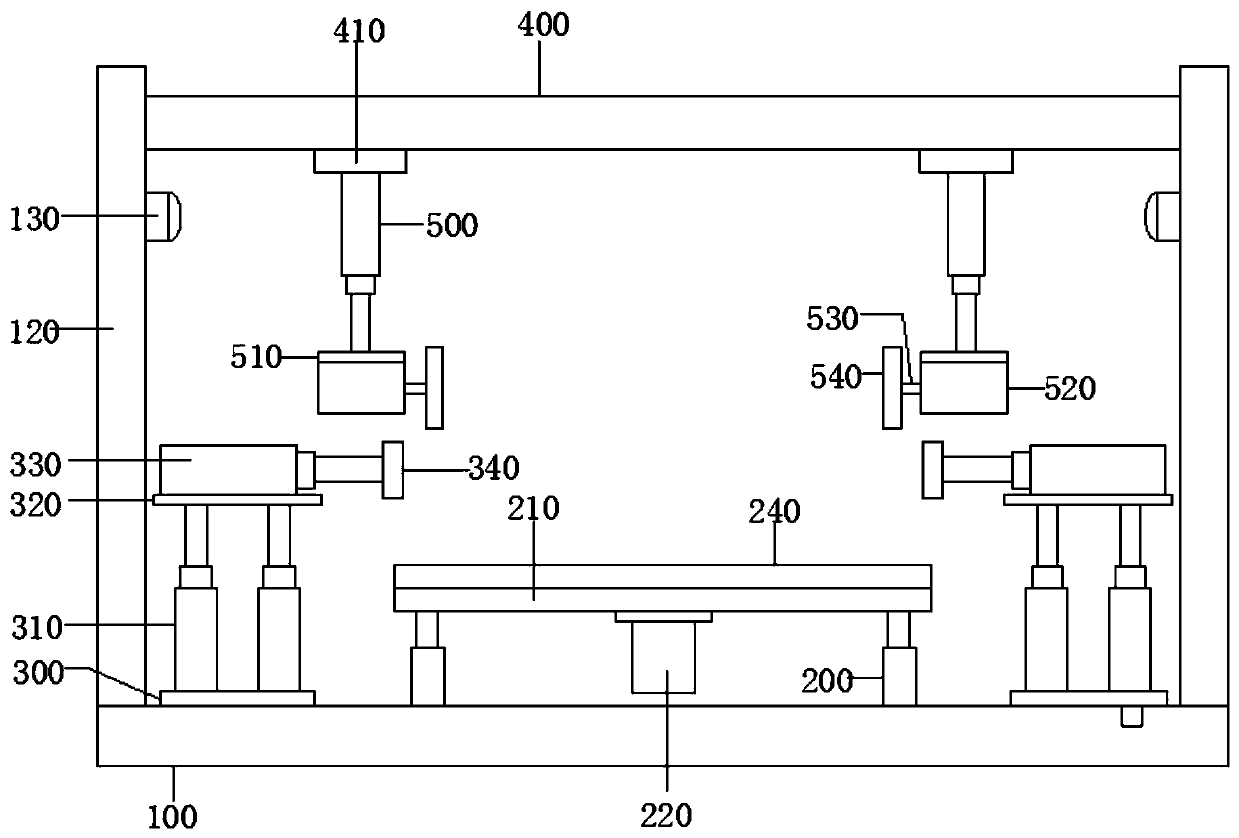

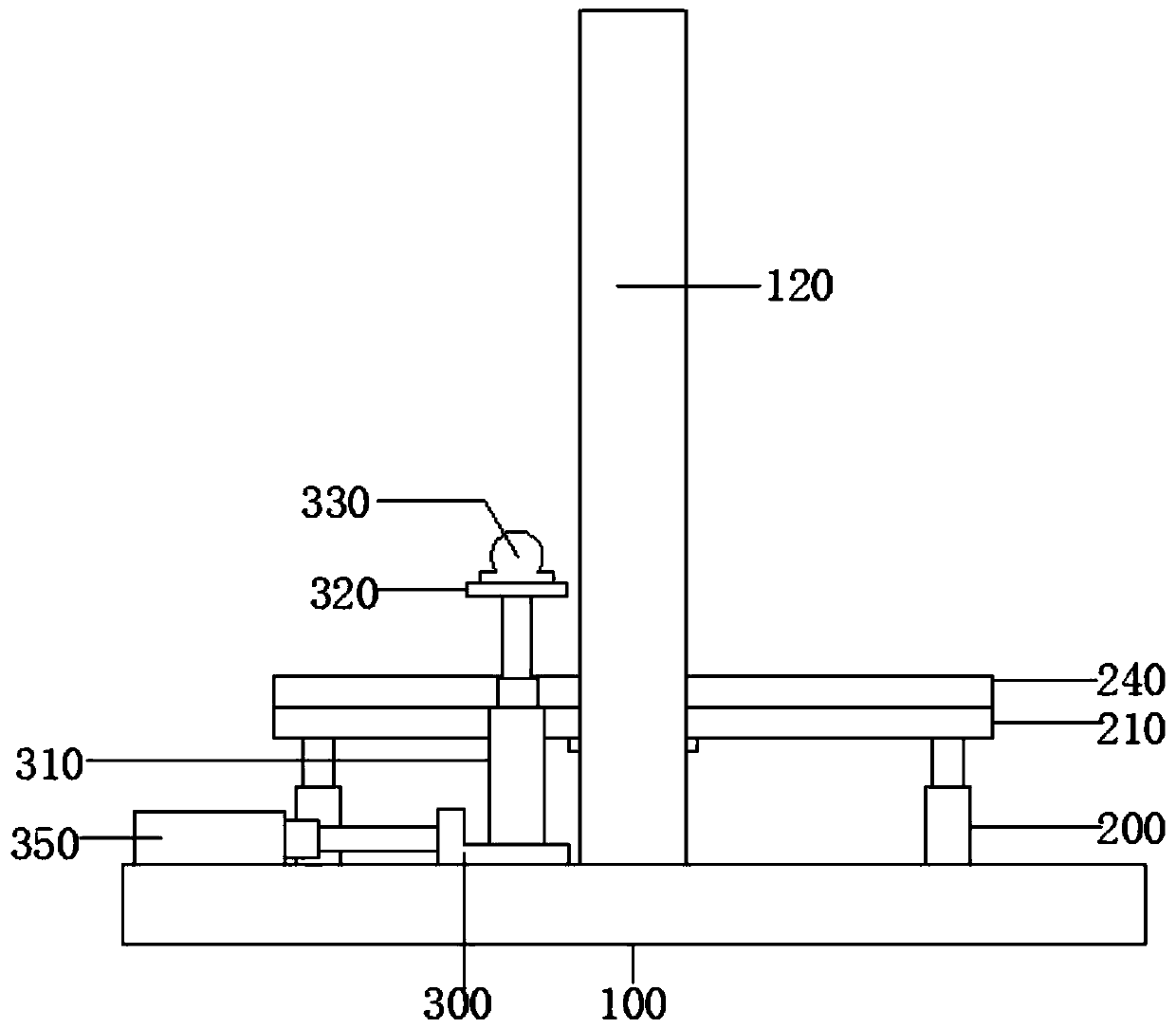

[0021] The invention provides a large-scale component rotation welding membrane, which can make the component rotate in a plane for welding, and can meet the requirements of welding processing for components of different sizes. The welding process of column members of different sizes is convenient for workers to operate, and avoids the waste of man-hours when workers walk back and forth during welding. Please refer to figure 1 , figure 2 , image 3 with Figure 4 , including: base 100, turntable hydraulic cylinder 200, slide plate 300, electric slide rail 400 and lifting hydraulic cylinder 500;

[0022] see figure 1 , figure 2 , image 3 with Figure 4 , the base 100 includes a chute 110 and a column 120. Specifically, the top left and right sides of the base 100 are provided with a chute 110, and the left and right sides of the top of the base 100 are welded with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com