Rectangular numerical control cutting device for simultaneously cutting four sides

A cutting equipment and quadrilateral technology, applied in sawing equipment, sawing components, circular saws, etc., can solve the problems of unreasonable recycling of cutting waste, large dust, poor operating environment, etc., achieve outstanding economic benefits and reduce cutting time , The effect of convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

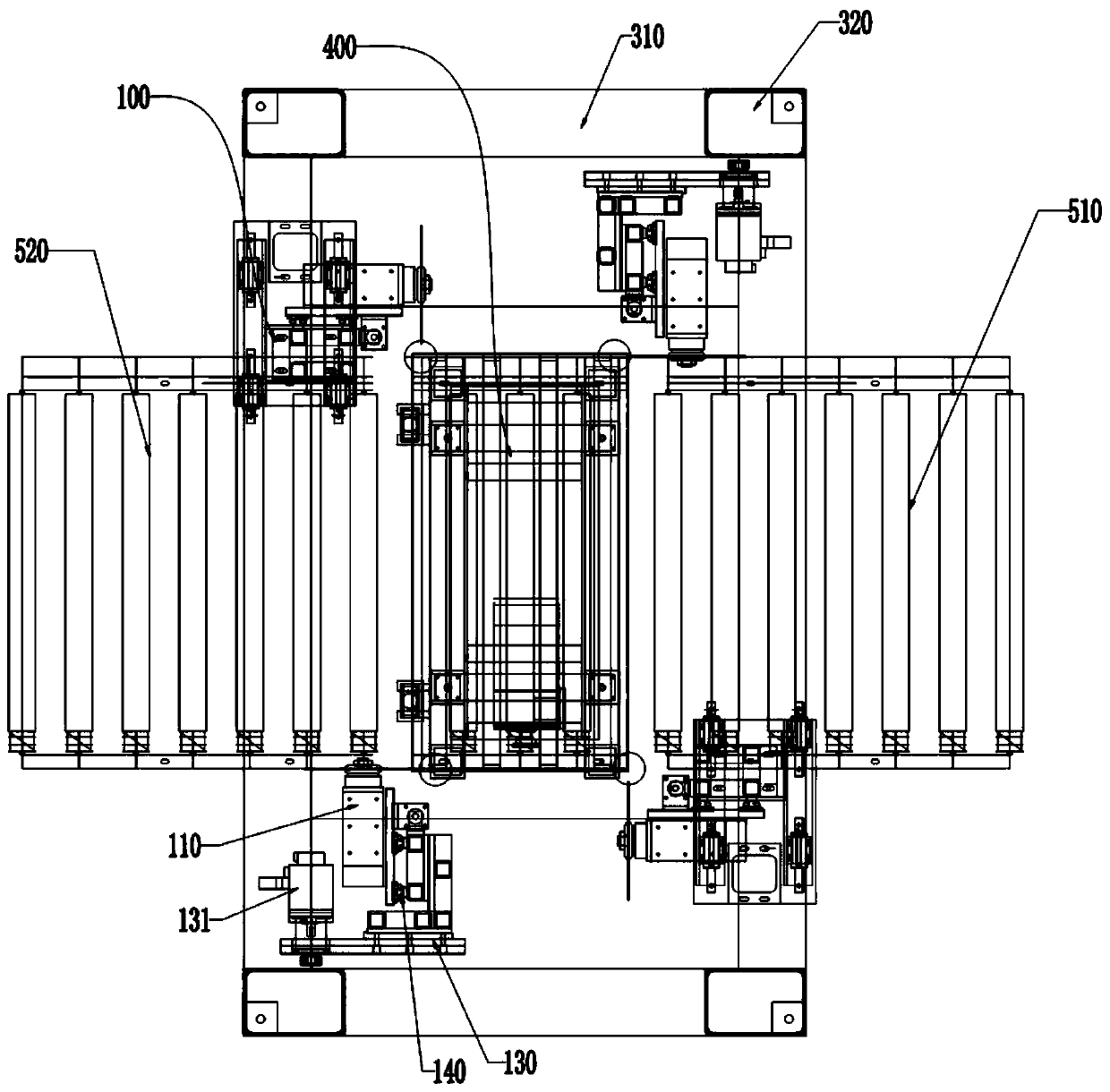

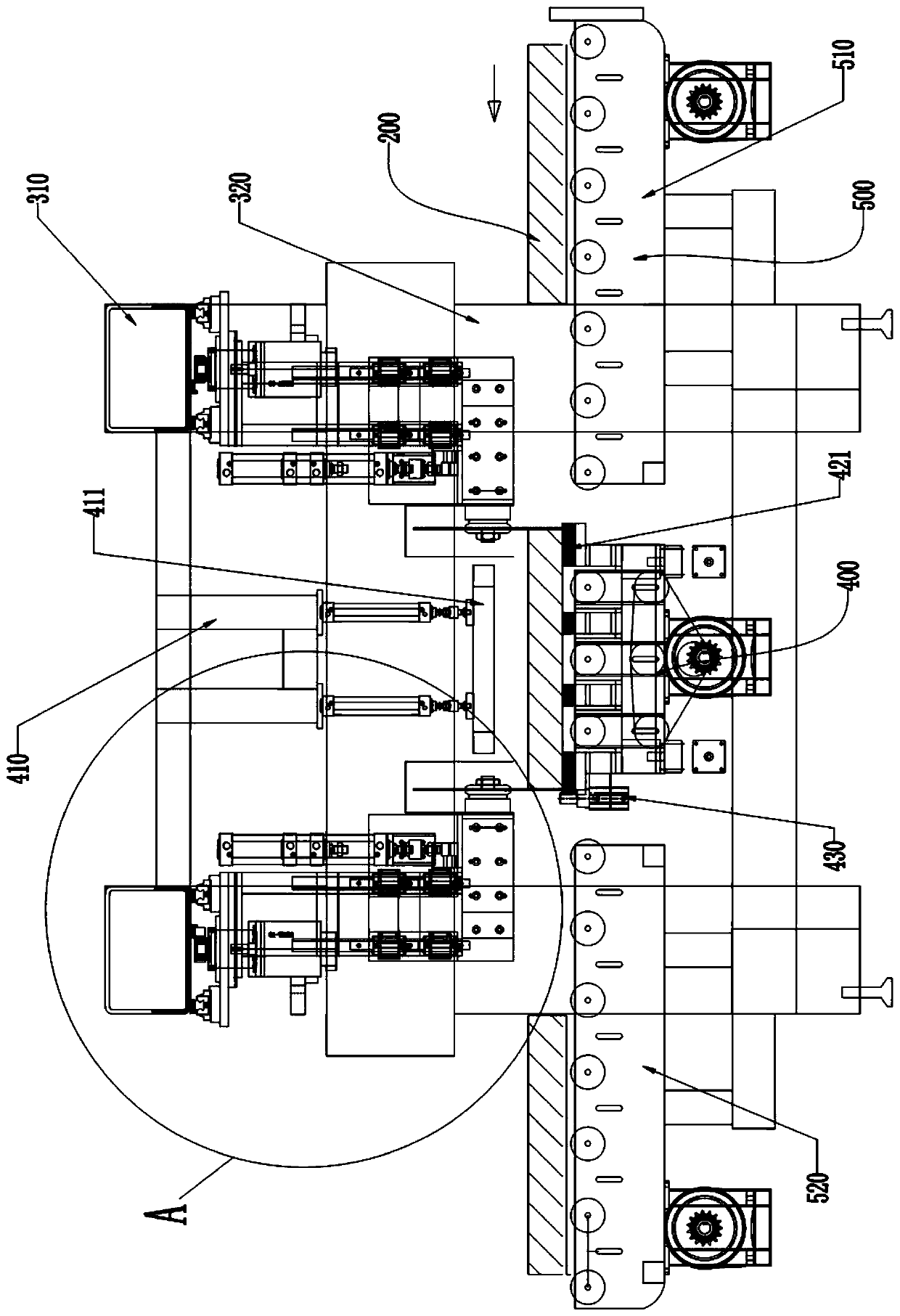

[0018] Such as Figure 1-Figure 4 As shown, a rectangular CNC cutting device with simultaneous cutting on four sides includes a cutting mechanism 100 for matching the working position of the cutting machine body. The cutting mechanism 100 has four knives 110 for cutting the material 200 to be processed. The end point of the quadrilateral is used as the starting point, and moves along the side length direction of the quadrilateral to form a closed cutting path. The cutting path of the material 200 to be processed through the cutter 110 realizes the quadrilateral cutting operation at the working position. Starting from the end point of the machine, it runs clockwise or counterclockwise to form a closed motion path. The cutting path also means the shape of the material to be processed 200 after cutting. The material to be processed 200 generally refers to wood, and the corresponding tool 110 is a saw blade. The consumption of circular saw blade is extremely low, the cutting accur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com