A method for using refining slag for converter smelting

A technology of refining slag and converter smelting, which is applied in the field of iron and steel smelting, and can solve problems such as inability to realize recycling, unsatisfactory recycling rate, and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

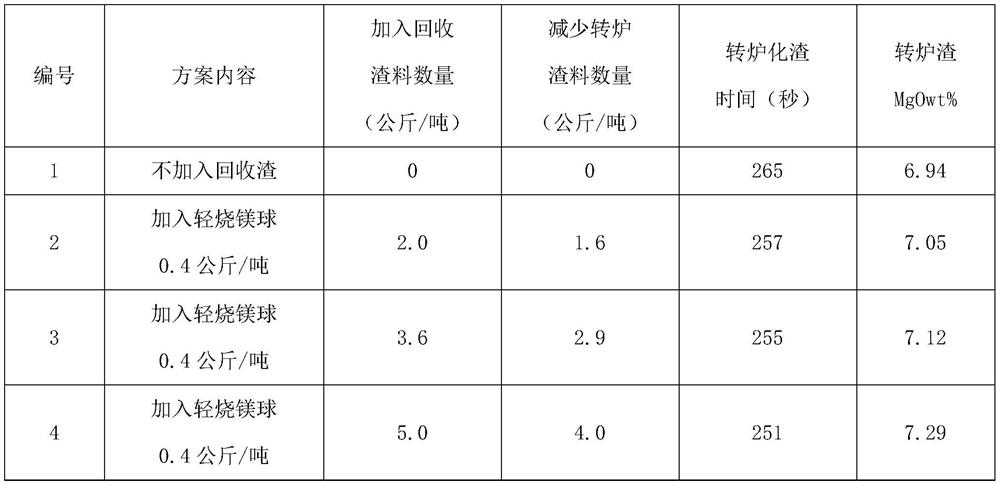

Embodiment 1

[0019] The operation method of the above-mentioned refining slag in converter smelting comprises the following steps:

[0020] Step 1. Adjusting the composition of refining slag: After the continuous casting pouring is completed, a certain amount of lightly burned magnesium balls are manually added into the ladle from the continuous casting platform. The content of MgO in the lightly burned magnesium balls is 60wt%, and the quantity is 0.4 kg / tons, thereby increasing the MgO content of the slag to meet the requirement that the MgO content during converter smelting be 7-8wt%;

[0021] Step 2. Refining slag cooling: Pour the hot refining slag into the slag basin using a crane, and transport it to the slag storage workshop by car to cool the slag naturally;

[0022] Step 3. Screening of refining slag: The cooled refining slag presents two forms of block and powder, and is screened. The screening specifications are 80*80mm and 30*30mm, and the screening specifications are between...

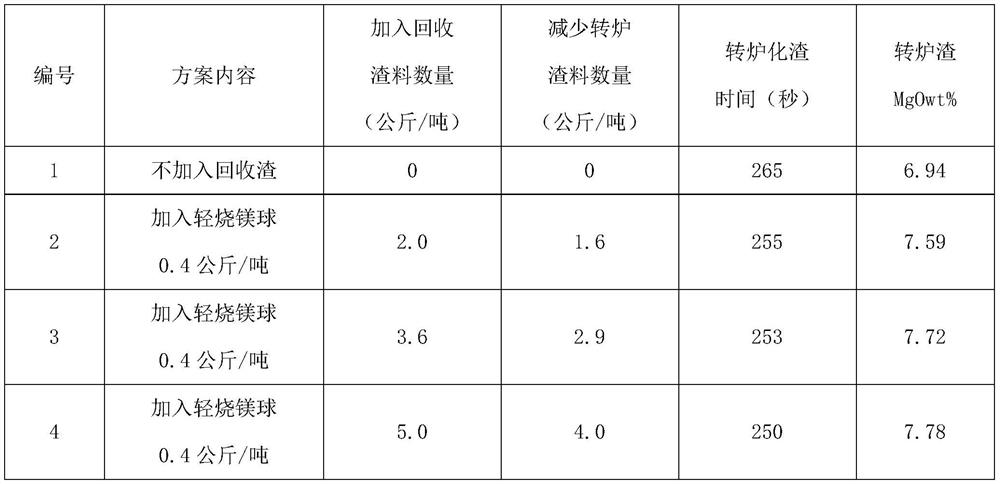

Embodiment 2

[0036] The operation method of the above-mentioned refining slag in converter smelting comprises the following steps:

[0037] Step 1. Adjusting the composition of refining slag: After the continuous casting pouring is completed, a certain amount of light-burned magnesium balls are manually added into the ladle from the continuous casting platform. The MgO content in the light-burned magnesium balls is 61wt%, and the quantity is 0.6 kg / tons, so as to increase the MgO content of the slag and meet the requirement that the MgO content of the converter smelting be 7-8wt%;

[0038] Step 2. Refining slag cooling: Pour the hot refining slag into the slag basin using a crane, and transport it to the slag storage workshop by car to cool the slag naturally;

[0039] Step 3. Screening of refining slag: The cooled refining slag presents two forms of block and powder, and is screened. The screening specifications are 80*80mm and 30*30mm, and the screening specifications are between 30-80m...

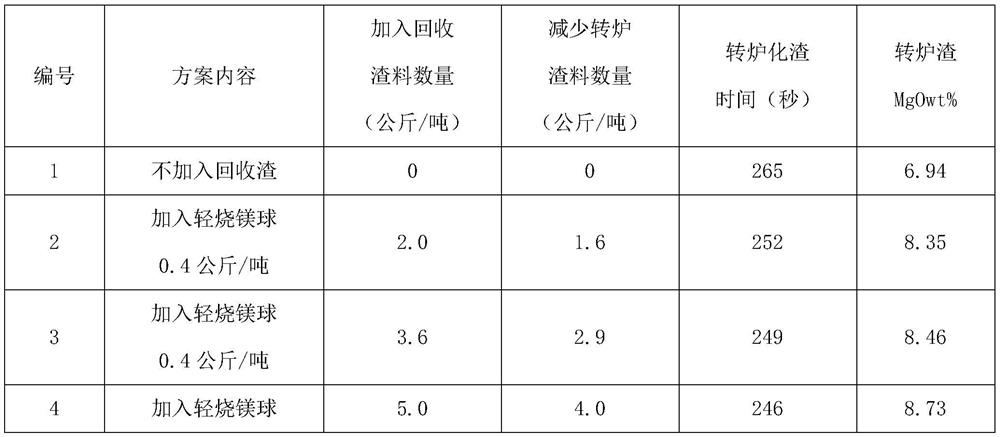

Embodiment 3

[0053] The operation method of the above-mentioned refining slag in converter smelting comprises the following steps:

[0054] Step 1. Adjusting the composition of refining slag: After the continuous casting pouring is completed, a certain amount of lightly burned magnesium balls are manually added into the ladle from the continuous casting platform. The MgO content in the lightly burned magnesium balls is 62wt%, and the quantity is 0.8 kg / tons, thereby increasing the MgO content of the slag and meeting the requirement that the MgO content of the converter smelting be 8-9 wt%;

[0055] Step 2. Refining slag cooling: Pour the hot refining slag into the slag basin using a crane, and transport it to the slag storage workshop by car to cool the slag naturally;

[0056] Step 3. Screening of refining slag: The cooled refining slag presents two forms of block and powder, and is screened. The screening specifications are 80*80mm and 30*30mm, and the screening specifications are betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com