Device for controlling acidity of electrodeposition solution and method thereof

A control method and electrowinning technology, which is applied in the direction of electrolysis process, electrolysis components, process efficiency improvement, etc., can solve the problems of solution pipe bursting, electrolytic tank bursting, etc., and achieve the effect of reducing the concentration of hydrogen ions and reducing risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

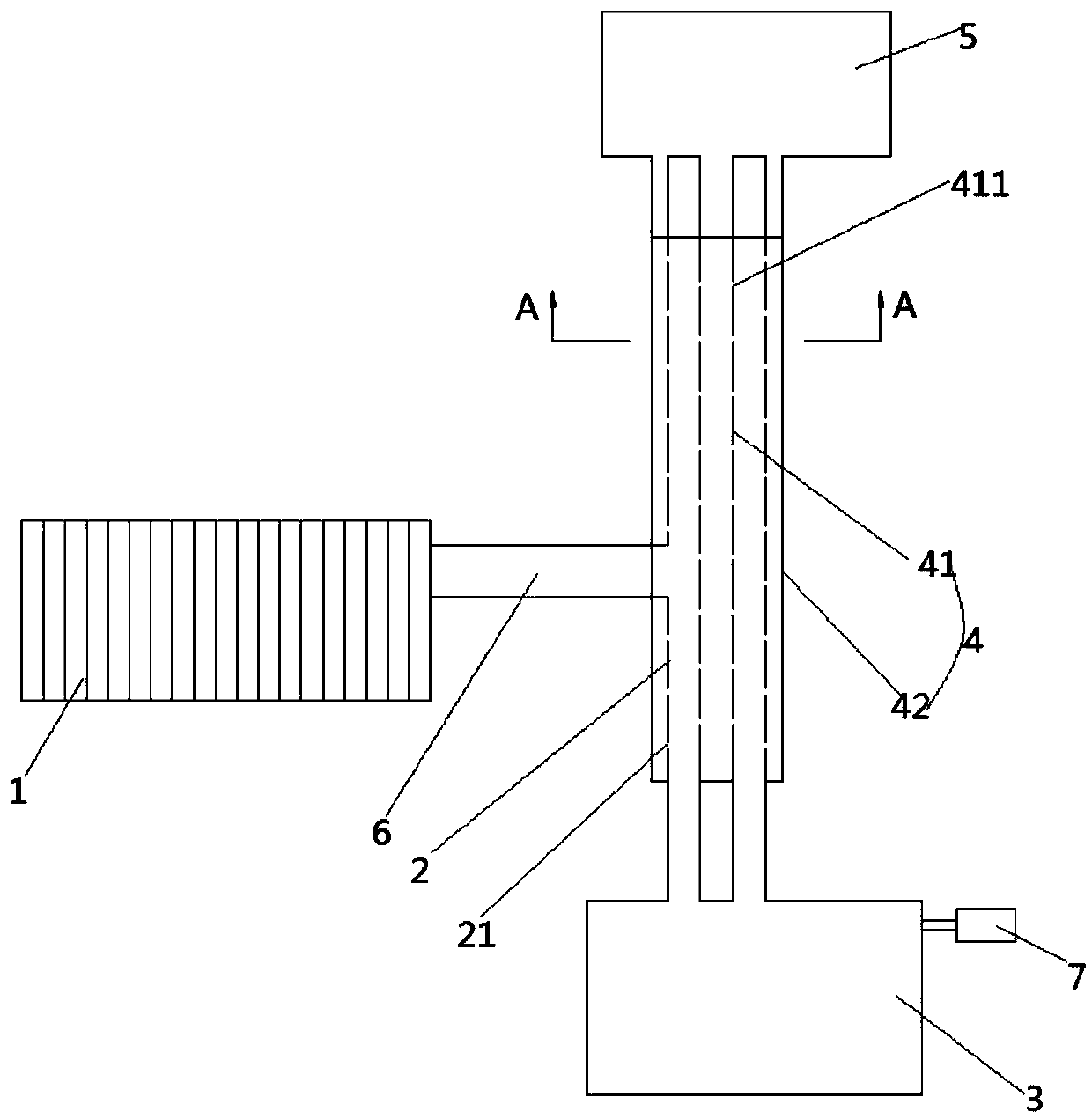

[0024] Embodiment 1 of the present invention provides a device for controlling the acidity of the electrowinning solution, referring to Figure 1-3 , including electrowinning tank 1, raffinate pipeline 2, raffinate tank 3, nitrogen pipeline group 4 and nitrogen storage tank 5, electrowinning tank 1 communicates with raffinate tank 3 through raffinate pipeline 2, and raffinate pipeline 2 also passes nitrogen gas The pipeline group 4 communicates with the nitrogen storage tank 5, and the nitrogen pipeline group 4 is used to feed nitrogen gas into the raffinate pipeline 2 to squeeze out the chlorine gas in the electrowinning residual liquid.

[0025] A liquid inlet pipe 6 is also included, and the liquid inlet pipe 6 is arranged on one side of the residual liquid pipeline 2 for communicating with the electrowinning tank 1 and the residual liquid pipeline 2 .

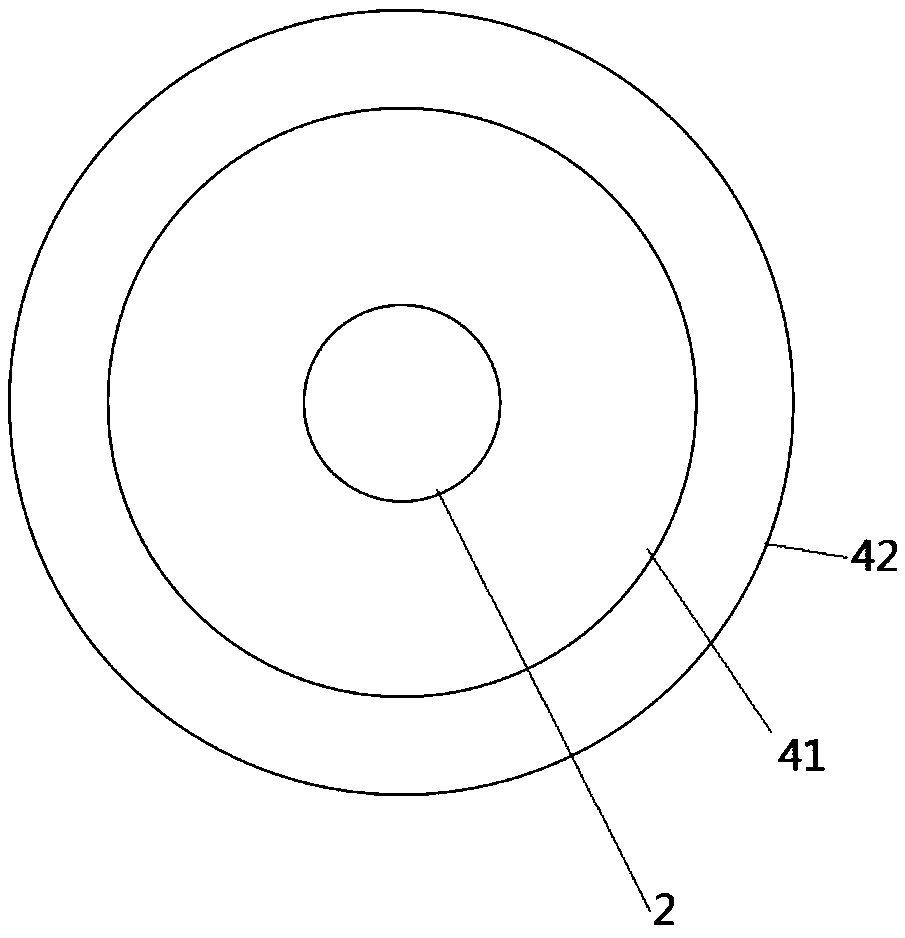

[0026] The nitrogen pipe group 4 includes an inner nitrogen pipe 41 and an outer nitrogen pipe 42, the inner nitrogen pip...

Embodiment 2

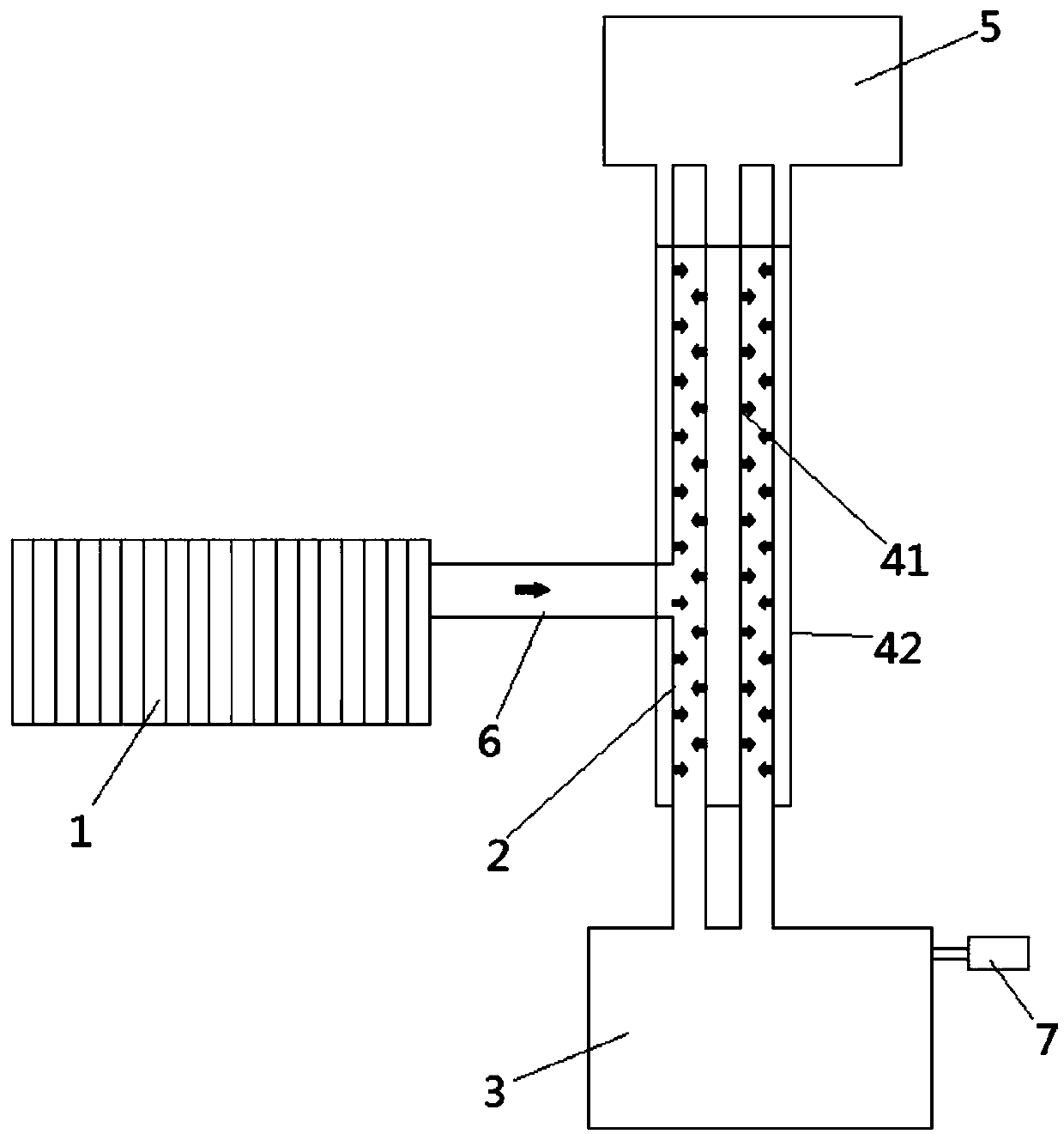

[0037] Embodiment 2 of the present invention provides a control method for controlling the acidity of the electrowinning solution. The method adopts a device for controlling the acidity of the electrowinning solution as described in Embodiment 1. The method is: along the nitrogen pipeline group 4 to the residual Nitrogen gas is fed into the liquid pipeline 2; the content of chloride ions in the electrowinning residual liquid is controlled by controlling the amount of nitrogen gas; the residual liquid in the residual liquid pipeline 2 and the residual liquid tank 3 is controlled according to the content of the chloride acidity.

[0038] Specifically: the nitrogen gas in the inner nitrogen pipe 41 and the outer nitrogen pipe 42 blows nitrogen gas into the residual liquid in the residual liquid pipeline 2 along the nitrogen gas outlet hole 411 and the nitrogen gas inlet hole 21 on the pipe surface respectively, so that the residual liquid in the residual liquid is " Boiling", so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com