Production method for explosive prevented from being unpacked and repeatedly packed and used

A production method and technology for explosives, applied in the field of explosives production, can solve the problems of inability to track and manage the flow, destroy and remove them, and achieve the effects of preventing unpacking and repacking, low production costs, and preventing evasion of supervision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

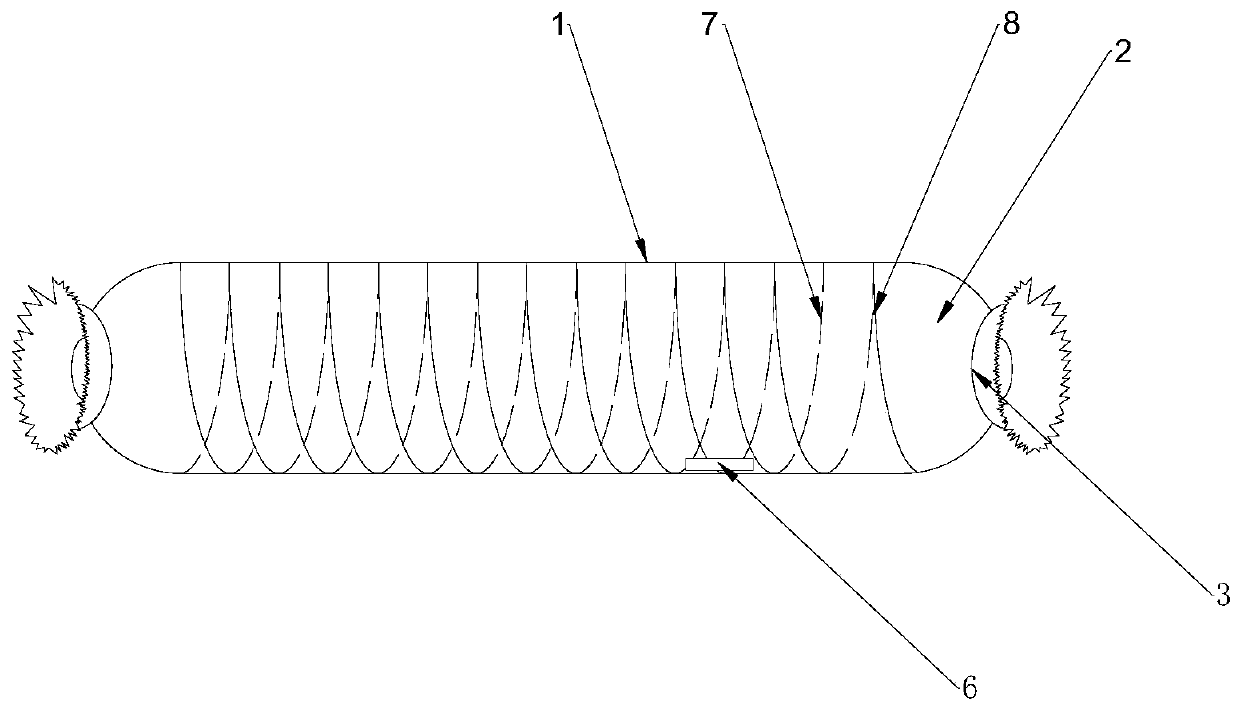

[0021] figure 1 Shown, the explosive in a kind of production method of the explosive that can prevent unpacking and repacking use of the present invention comprises colloidal emulsified explosive, water-gel explosive and powdery explosive, and the operating steps of its production are as follows:

[0022] The first step of charging: the explosive 2, the breaking agent and the built-in tracking supervision mark 6 are loaded into the plastic film 1 according to the process requirements; the breaking agent includes A component 4 and B component 5, and the A component is a double Phenol A-type epoxy resin, B component is diethylene triamine, according to the mass ratio A:B=10:1, it is injected into the plastic film 1 by spiral, so that both A component 4 and B component 5 are Helically distributed and staggered in explosives; once the explosive packaging unit is unpacked and repacked, component A and component B meet and immediately undergo a chemical reaction to form an epoxy res...

Embodiment 2

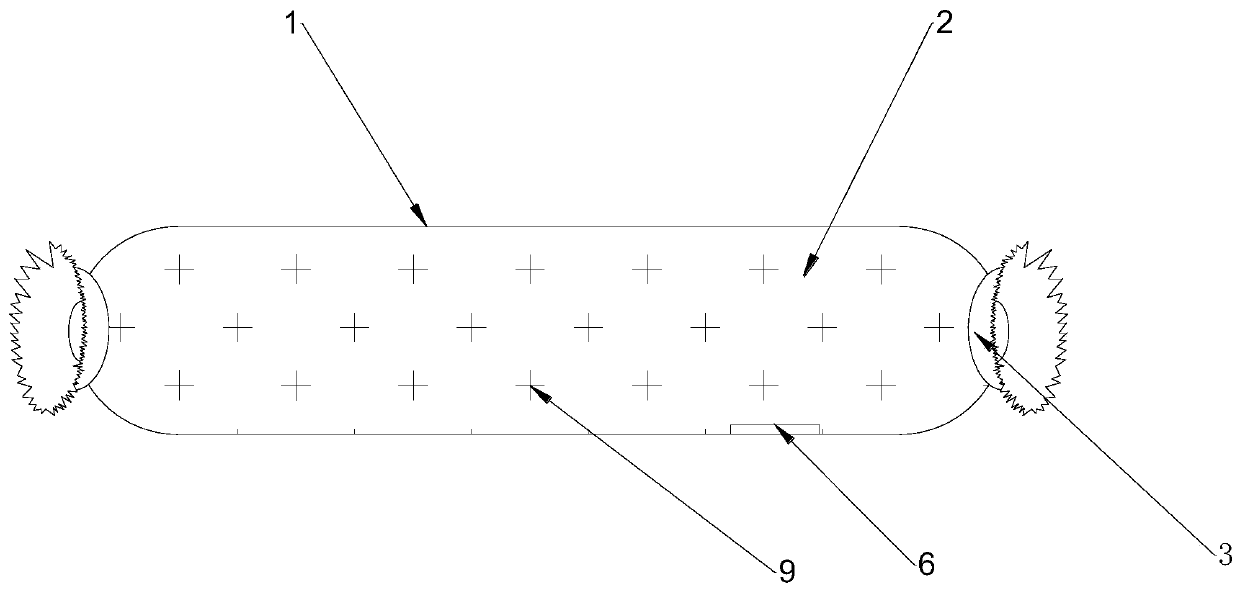

[0027] figure 2 Shown, the explosive in a kind of production method of the explosive that can prevent unpacking and repacking use of the present invention is powdery explosive, and the operating steps of its production are as follows:

[0028] The first step of charging: put the explosive 2, the breaking agent and the built-in tracking supervision mark 6 into the plastic film 1 according to the process requirements; the breaking agent adopts a hygroscopic agent, and the hygroscopic agent is powdered sodium chloride or powdered calcium carbonate One of them is linearly injected into the plastic film 1 by uniformly mixing with powdered explosives; once the explosive packaging unit is unpacked and subpackaged, the hygroscopic agent will contact with the air and be damp, causing the explosive to deteriorate rapidly and become invalid;

[0029] The second part of sealing: immediately after the charging is completed, the two ends of the buckle 3 and the explosive roll are sealed; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com