Integrated mobile intelligent pressure test integrated device

A pressure test and mobile intelligent technology, applied in the direction of measuring devices, using stable tension/pressure testing material strength, instruments, etc., can solve the problems of complex pipeline process and difficult pressure test, so as to avoid safety hazards and labor intensity The effect of reducing and maintaining pressure is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

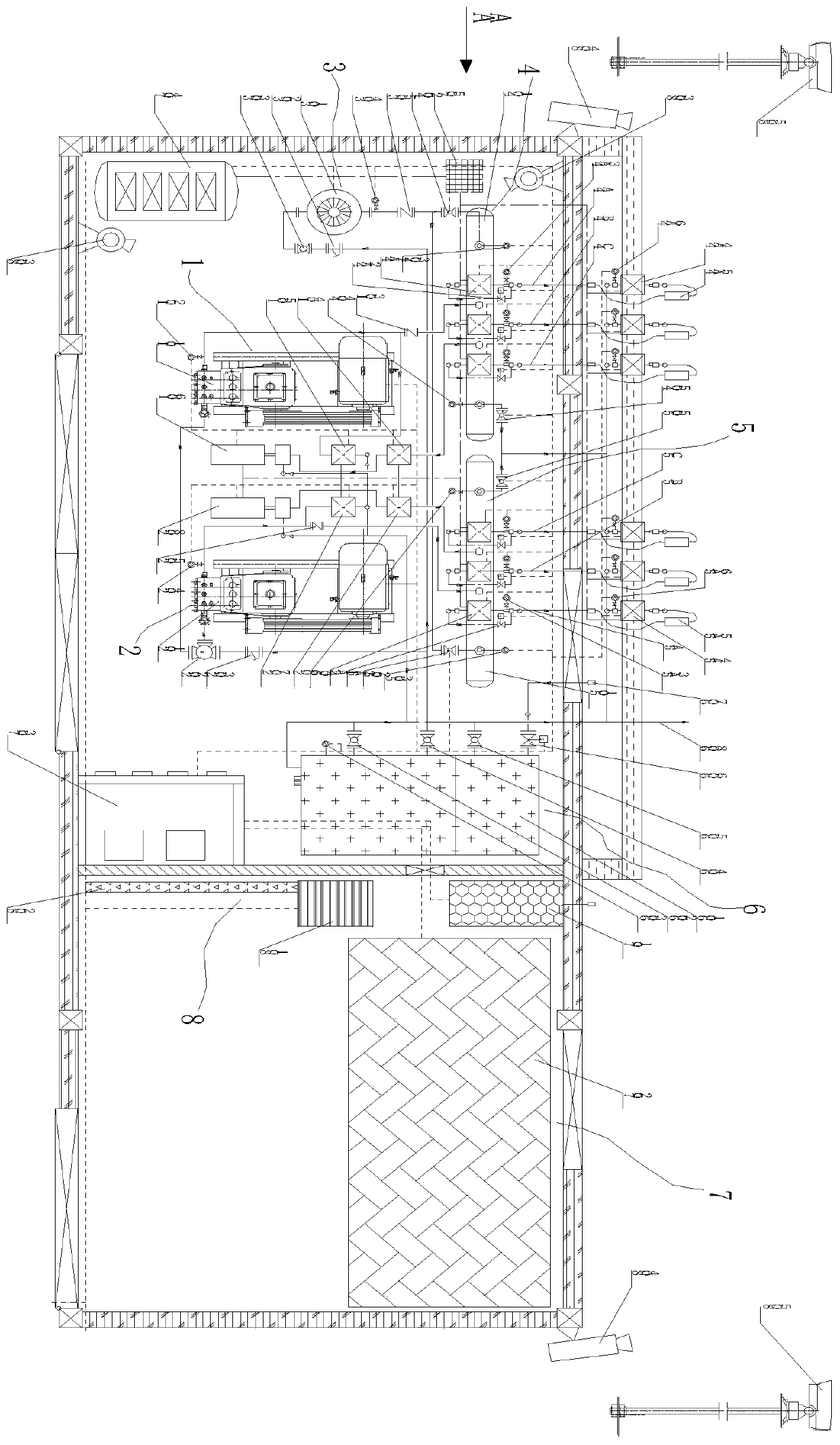

[0026] according to figure 1 An integrated mobile intelligent pressure test integrated device shown, the pressure test water tank unit 6, the injection pump unit 3, the first high pressure pump unit 1, the second high pressure pump unit 2, the first water collector unit 4, the second The water collector unit 5 and the pressure test monitoring and control unit 7; the pressure test water tank unit 6 is provided with a water inlet, a water outlet and a sewage bus 608, and the water outlet of the pressure test water tank unit 6 is respectively connected with the water injection pump unit 3 , The first high-pressure pump unit 1 and the second high-pressure pump unit 2 are connected to supply water for the water injection pump unit 3, the first high-pressure pump unit 1 and the second high-pressure pump unit 2; The water collector unit 4 and the second water collector unit 5 are in communication; the first water collector unit 4 is also communicated with the first high pressure pump...

Embodiment 2

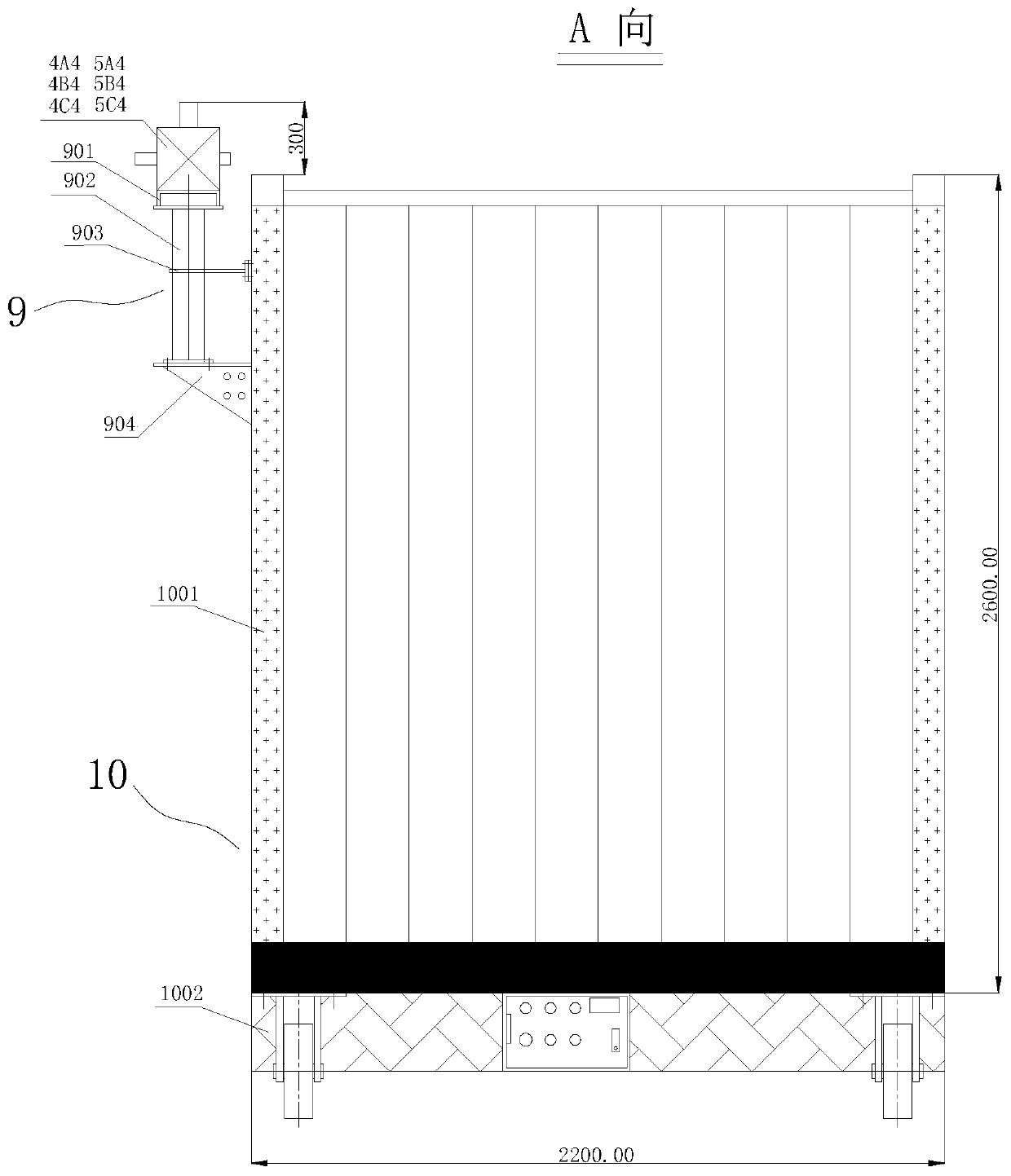

[0030] according to figure 1 and figure 2 The shown integrated mobile intelligent pressure test integrated device is different from the first embodiment in that it also includes a container-type mobile platform 10; the container-type mobile platform 10 includes a multi-functional container 1001 and a trackless electric mobile platform 1002 ; The multifunctional container 1001 is connected to the trackless electric mobile platform 1002; the multifunctional container 1001 is provided with an equipment room and a monitoring operation room, and the equipment room and the monitoring operation room are respectively provided with doors; the first high-pressure pump unit 1. The second high pressure pump unit 2, the injection pump unit 3, the first water collector unit 4, the second water collector unit 5 and the pressure test water tank unit 6 are all arranged in the equipment room, and the pressure test monitoring The control unit 7 is arranged in the equipment room or the monitori...

Embodiment 3

[0037] according to figure 1 The shown integrated mobile intelligent pressure test integrated device is different from the first embodiment in that: the first high-pressure pump unit 1 includes a first high-pressure pump 101, a first pump-end pressure transmitter 102, a first high-pressure pump A one-way valve 103, a first container valve 104, a first pump-end valve 105 and a first servo relief valve 106; the outlet of the first high-pressure pump 101 is connected to the first one-way valve 103 and the first pump-end valve respectively 105 is connected to the inlet, the inlet of the first high-pressure pump 101 is connected to the inlet of the second high-pressure pump unit 2; the outlet of the first one-way valve 103 is connected to the first water collector unit 4; the first pump end pressure The transmitter 102 is arranged at the outlet end of the first high pressure pump 101; the outlet of the first pump end valve 105 is connected to the drain bus 608 of the pressure test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com