Half-cut liquid crystal film and processing method

A processing method and technology of liquid crystal film, applied in nonlinear optics, instruments, optics, etc., can solve the problems of short circuit, electrical performance failure of liquid crystal film, easy short circuit and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

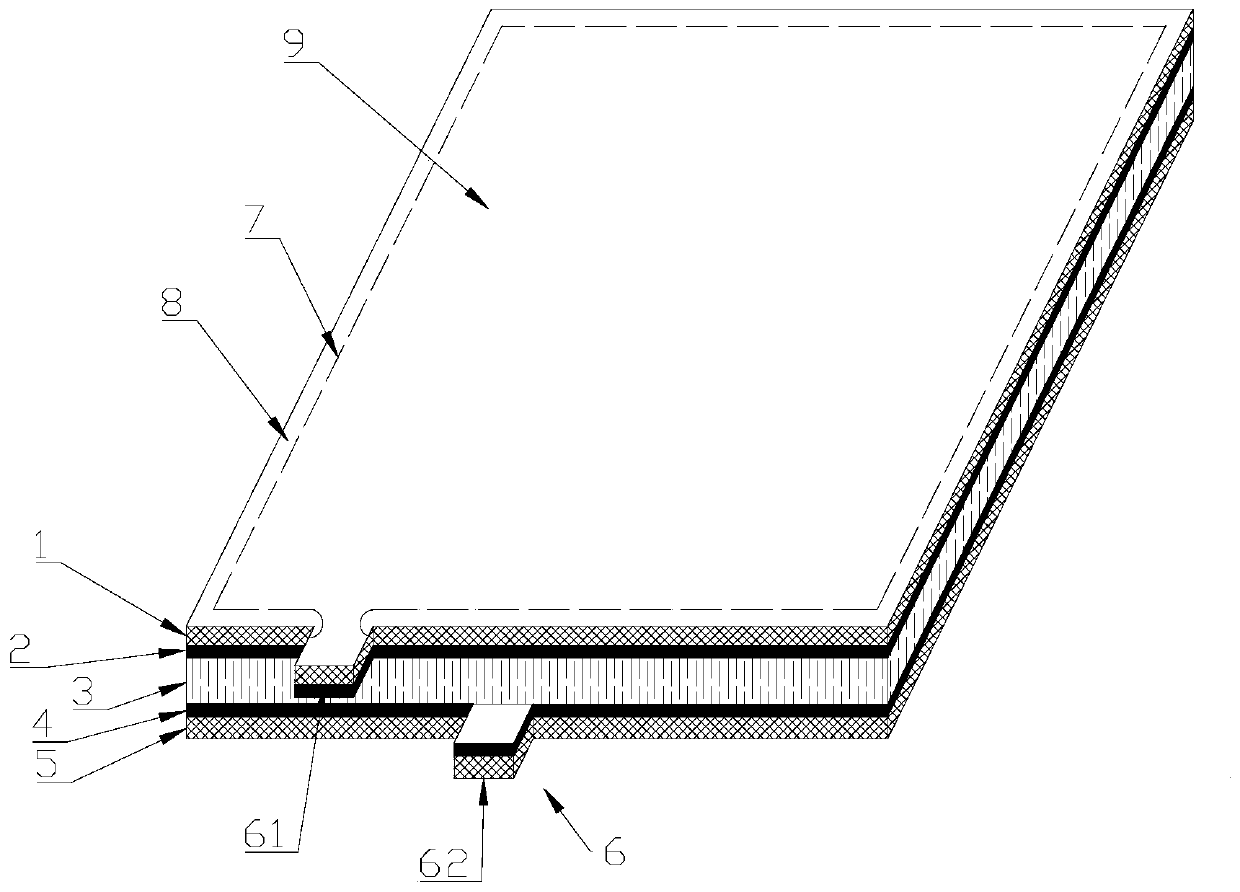

[0051] The half-cut line 7 penetrates vertically from the surface of the first substrate 1 toward the direction of the liquid crystal layer 3 , and its depth reaches at least the surface of the first conductive layer 2 facing away from the first substrate 1 . For example, the half-cut line 7 may go deep into the liquid crystal layer 3 , or the half-cut line 7 may go deep into the joint of the first conductive layer 2 and the liquid crystal layer 3 . In order to control the cutting depth conveniently, the half-cutting line 7 preferably goes deep into the liquid crystal layer 3 , so that it can guarantee cutting the first conductive layer 2 without cutting the second conductive layer 4 . For the convenience of description, in this embodiment, the half cut 7 goes deep into the liquid crystal layer 3 as an example for description. When the depth of the half-cut 7 is different, the same technical effect can be achieved by making adaptive modifications according to the content of t...

Embodiment 2

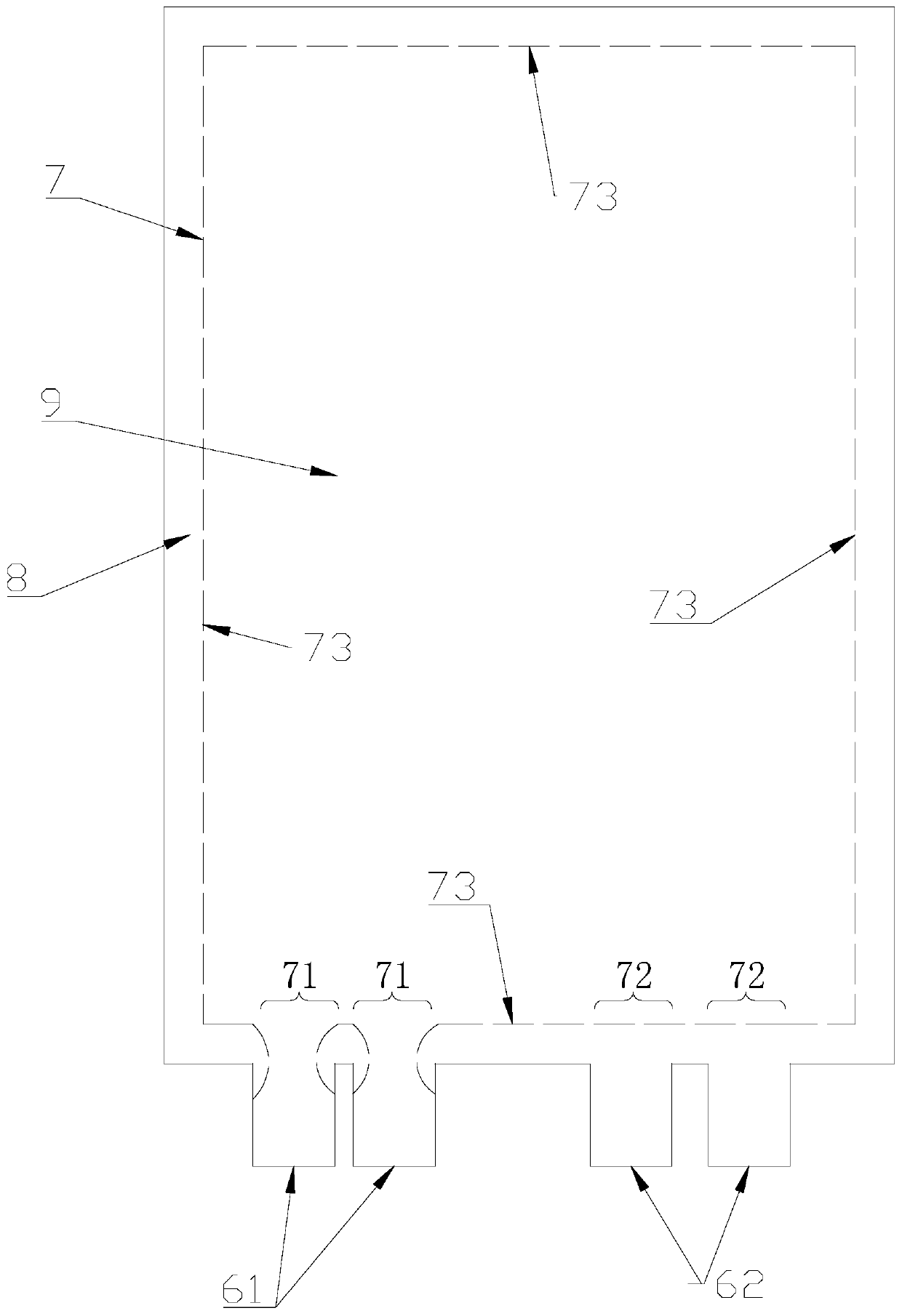

[0066] The half-cut line 7 penetrates vertically from the surface of the second substrate 5 toward the direction of the liquid crystal layer 3 , and its depth reaches at least the surface of the second conductive layer 4 facing away from the second substrate 5 . For example, the half-cut line 7 may go deep into the liquid crystal layer 3 , or the half-cut line 7 may go deep into the joint of the second conductive layer 4 and the liquid crystal layer 3 . In order to control the cutting depth conveniently, the half-cutting line 7 preferably goes deep into the liquid crystal layer 3 , so that it can guarantee cutting the second conductive layer 4 without cutting the first conductive layer 2 .

[0067] Such as Figure 4 , Figure 5 As shown, the half cut line 7 divides the liquid crystal film into an outer ring portion 8 and an inner ring portion 9 . Among them, what is located inside the half-cut line 7 is the inner ring portion 9 , and what is located outside the half-cut lin...

Embodiment 3

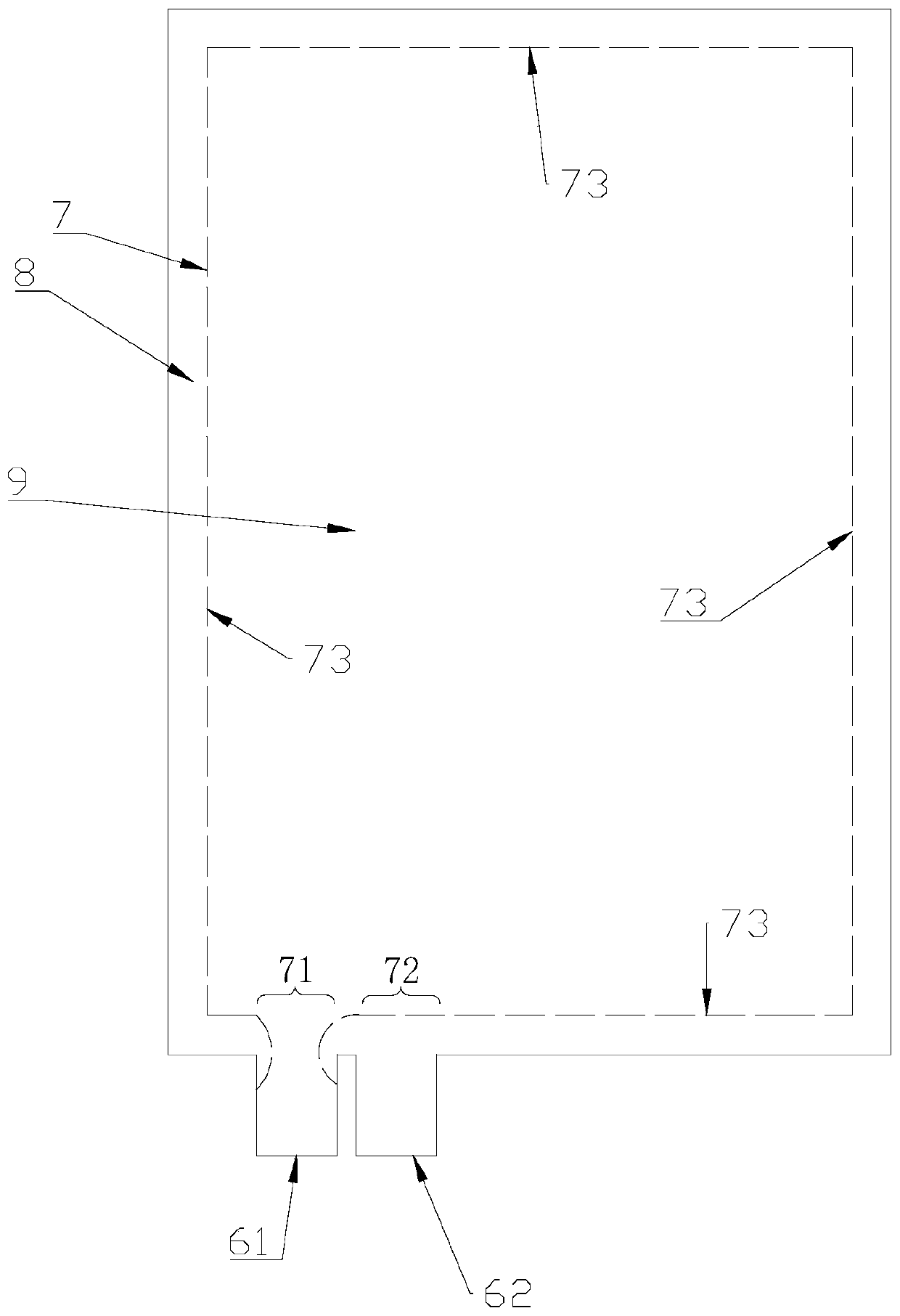

[0081] The half-cutting line 7 penetrates vertically from the surface of the first substrate 1 or the second substrate 5 to the direction of the liquid crystal layer 3, and its deep depth needs to ensure that at least one conductive layer is cut, and that the entire liquid crystal film does not was cut off. For example, the half-cut line 7 can go deep into the liquid crystal layer 3, or the half-cut line 7 can go deep into the joint position of the second conductive layer 4 and the liquid crystal layer 3, or the half-cut line 7 can go deep into the liquid crystal layer 3. The part where the liquid crystal layer 3 is combined with the first conductive layer 2, or the half-cut line 7 can go deep into the second substrate 5 from the direction of the first substrate 1 without cutting the second substrate 5, or the half-cut line 7 can be formed by The direction of the second substrate 5 penetrates into the first substrate 1 without cutting the first substrate 1 .

[0082] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com