High-gloss high-DOI waterborne polyurethane coating as well as preparation method and application thereof

A water-based polyurethane, high-gloss technology, used in polyurea/polyurethane coatings, coatings, etc., can solve the problems of orange peel, poor fullness, and high haze

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

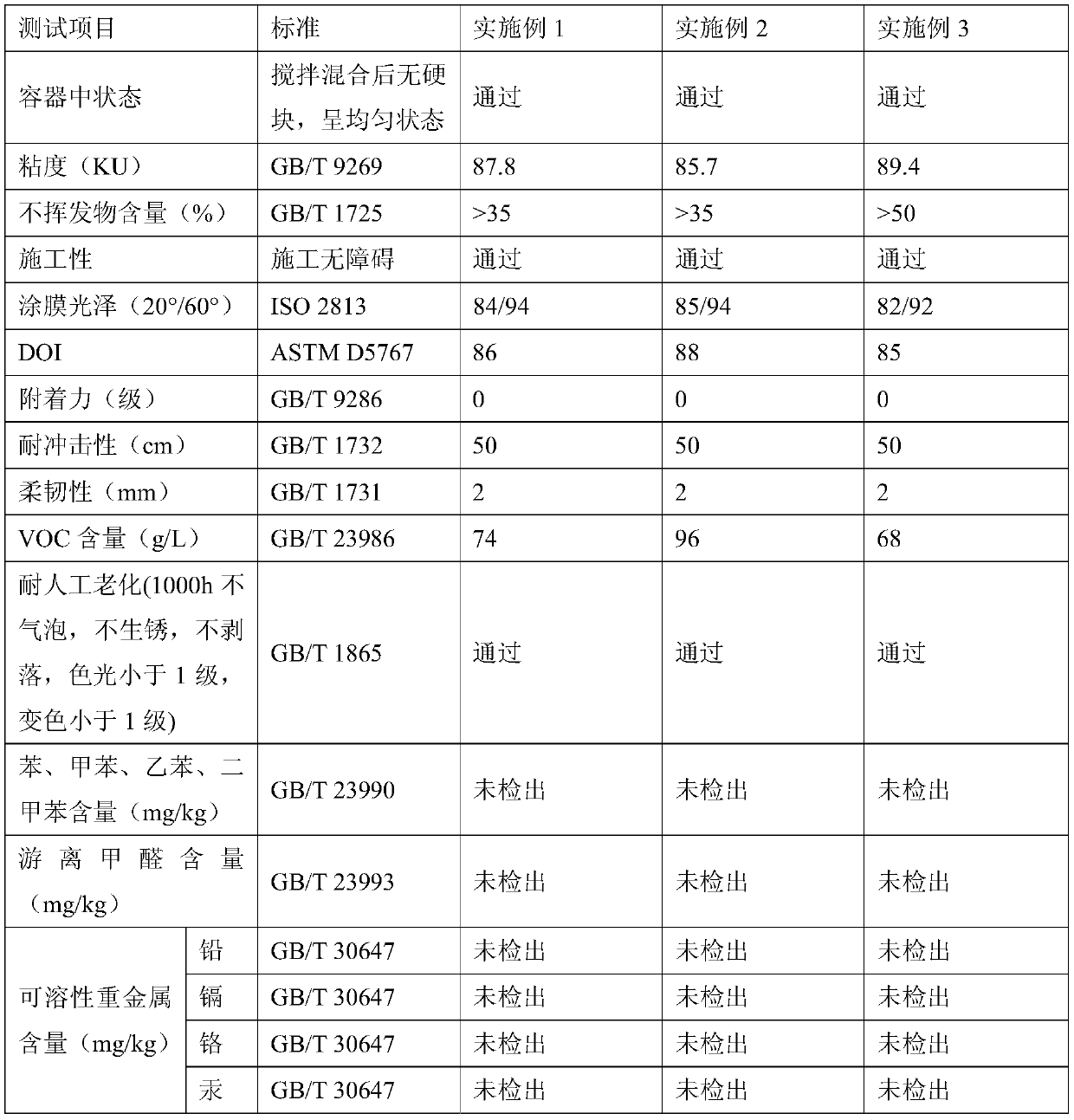

Examples

Embodiment 1

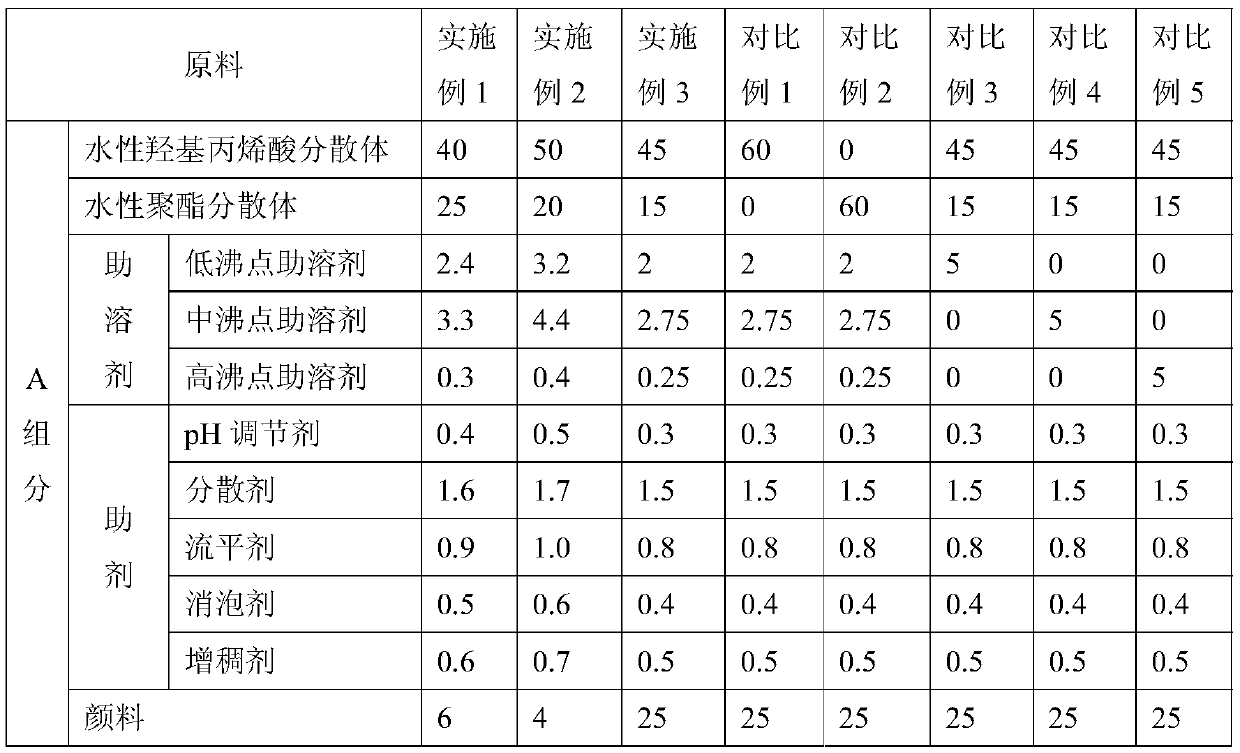

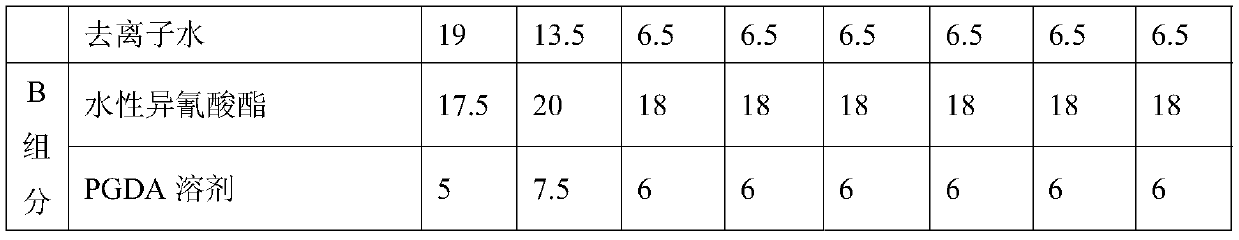

[0038] A high gloss and high DOI polyurethane coating, the coating includes A component and B component,

[0039] Component A consists of the following raw materials: aqueous hydroxyacrylic dispersion (Bayhydrol xp 2470 from Covestro), aqueous polyester dispersion (NECOWEL 720 from ASK Chemicals GmbH), co-solvents, additives, pigments (Clariant) and deionized water,

[0040] Wherein, cosolvent comprises low boiling point cosolvent (BCS), middle boiling point cosolvent (DPM) and high boiling point cosolvent (DPnB),

[0041] Additives include pH adjuster (DMEA), dispersant (BYK 2012), non-silicon leveling agent (wet510 from Tego), defoamer (BYK 011) and thickener (299 from Hemingstec) ;

[0042] Component B includes raw materials: water-based isocyanate and PGDA solvent;

[0043] The dosage of each raw material of component A and component B is shown in Table 1 below;

[0044] The preparation method of present embodiment coating comprises the steps:

[0045] S1: Preparation...

Embodiment 2

[0051] A high gloss and high DOI polyurethane coating, the coating includes A component and B component,

[0052] Component A includes the following raw materials: water-based hydroxyl acrylic dispersion (Bayhydrol xp 2470 from Covestro), water-based polyester dispersion (NECOWEL 720 from ASK Chemicals GmbH), co-solvents, additives, pigments (Yipin) and deionized water ,

[0053] Wherein, cosolvent comprises low boiling point cosolvent (BCS), medium boiling point cosolvent (PGDA) and high boiling point cosolvent (DPnB),

[0054] Auxiliaries include pH adjuster (DMEA), dispersant (DEGO’s 755W), non-silicon leveling agent (Euca’s 350W), defoamer (BYK 011) and thickener (OMG’s 0434);

[0055] Component B includes raw materials: water-based isocyanate and PGDA solvent;

[0056] The dosage of each raw material of component A and component B is shown in Table 1 below;

[0057] The preparation method of the coating of this embodiment is the same as that of Example 1.

Embodiment 3

[0059] A high gloss and high DOI polyurethane coating, the coating includes A component and B component,

[0060]Component A consists of the following raw materials: aqueous hydroxyacrylic dispersion (Bayhydrol xp 2470 from Covestro), aqueous polyester dispersion (NECOWEL 720 from ASK Chemicals GmbH), co-solvents, additives, pigments (Clariant) and deionized water,

[0061] Wherein, cosolvent comprises low boiling point cosolvent (BCS), middle boiling point cosolvent (DPM) and high boiling point cosolvent (DPnB),

[0062] Additives include pH adjuster (DMEA), dispersant (BYK 2012), non-silicon leveling agent (wet510 from Tego), defoamer (BYK 011) and thickener (299 from Hemingstec) ;

[0063] Component B includes raw materials: water-based isocyanate and PGDA solvent;

[0064] The dosage of each raw material of component A and component B is shown in Table 1 below;

[0065] The preparation method of the coating of this embodiment is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com