Constant temperature box system and its control method

A control method and the technology of the constant temperature box, which are applied to household refrigeration devices, instruments, lighting and heating equipment, etc., can solve the problems of poor internal layout planning of the constant temperature box room, failure to improve the use environment grade, and different power levels, etc., to achieve It is convenient for layout planning, improves the use environment grade, and realizes the effect of collection and recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

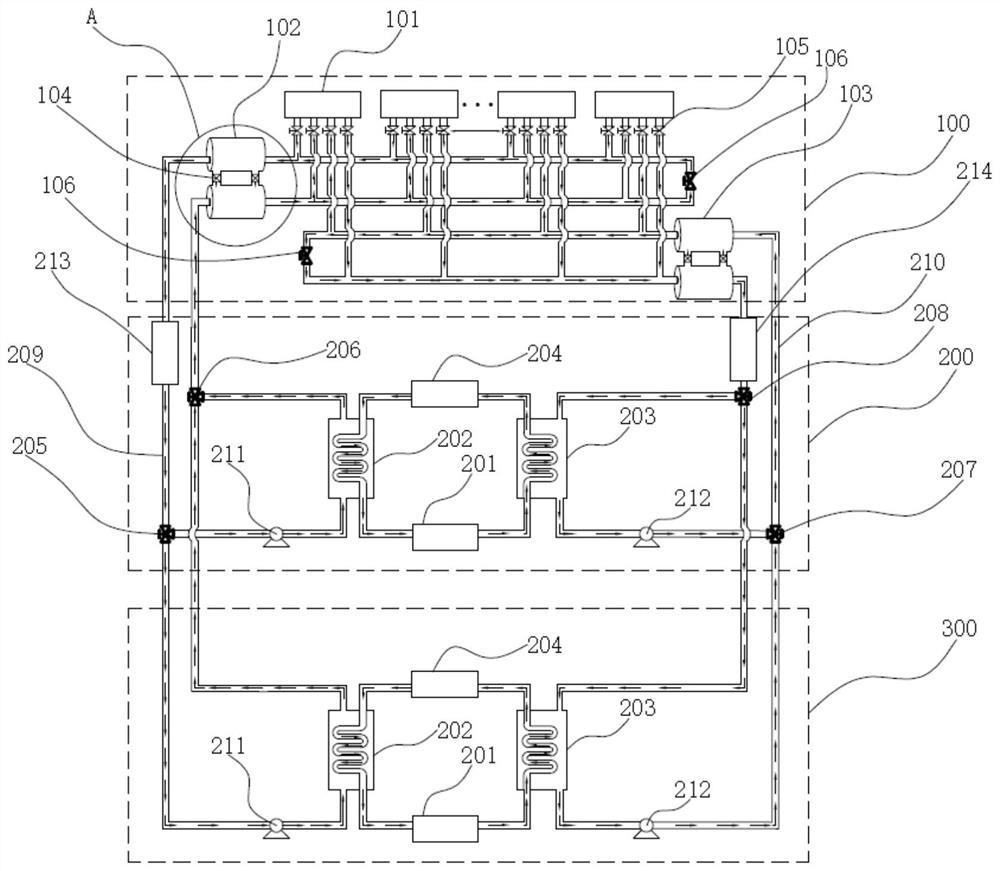

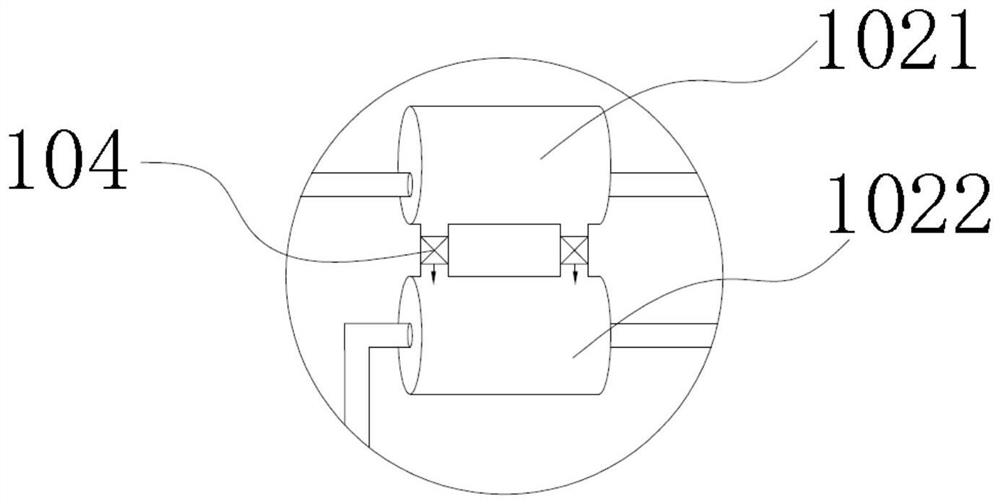

[0039] refer to Figure 1-Figure 2 , shows the structural block diagram and control block diagram of the thermostatic box control system in the embodiment of the present invention, the thermostatic box control system includes the central control system 200, the thermostatic box system 100 and the medium pipeline, and the central control system 200 is connected to the thermostatic box system through the medium pipeline 100. The incubator system 100 includes at least two incubators 101, wherein the central control system 200 is used to provide the temperature-regulating medium to the incubator system 100, and the central control system 200 can provide the incubator System 100 provides a temperature regulating medium.

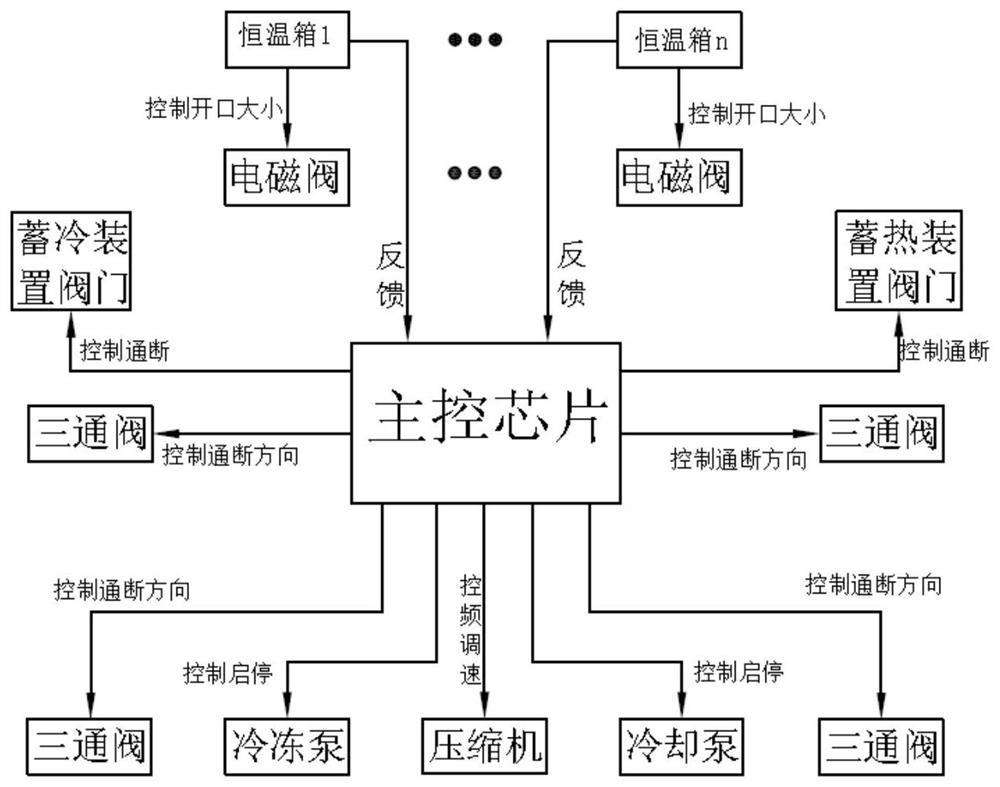

[0040] In a specific implementation, the central control system 200 includes a main control system, which includes control elements such as a main control device, a temperature controller, a humidity controller, and a valve controller. Parts of the work, to achie...

Embodiment 2

[0054] Embodiment 2 is provided based on Embodiment 1. Embodiment 2 specifically describes the structure of the central control system 200. The central control system 200 includes a refrigeration device, a condensation device, an evaporation device and an expansion valve 204. Optionally, the refrigeration device is a compressor 201. , the condensing device is a condenser 203, and the evaporating device is an evaporator 202; wherein, the compressor 201 is connected to the evaporator 202 through a medium pipeline, the evaporator 202 is connected to the expansion valve 204, and the expansion valve 204 is connected to the condenser 203, and the condenser 203 is connected with the compressor The machine 201 is connected, and a refrigeration cycle is formed through the above connection, and the circuit is used to generate cooling medium and heating medium.

[0055] In a specific implementation mode, the compressor 201 uses the refrigerant in the medium pipeline to perform high-pressu...

Embodiment 3

[0060] Embodiment 3 is provided on the basis of Embodiment 2. Embodiment 3 further provides a backup control system 300. It can be understood that the configuration of the backup control system 300 is consistent with that of the central control system 200. The cooling medium pipeline of the backup control system 300 209 and the heating medium pipeline 210 are respectively connected to the incubator system 100 through the first breaking device 205, the second breaking device 206, the third breaking device 207 and the fourth breaking device 208, so that the incubator 101 of the present invention The control system has two sets of control systems. When the central control system 200 fails or the temperature adjustment medium supplied by the central control system 200 is insufficient, the main control device controls the opening and closing of each three-way valve and connects to the backup control system 300. At this time, the backup control The system 300 can supplement the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com