Aluminum paste gas protection ball milling system

A technology of gas protection and aluminum-silver paste, applied in the direction of grain processing, etc., can solve the problems of easy oxidation of aluminum-silver paste, low production efficiency of aluminum-silver paste, low kerosene recovery utilization rate, etc., to avoid blockage, avoid oxidation, and avoid burning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

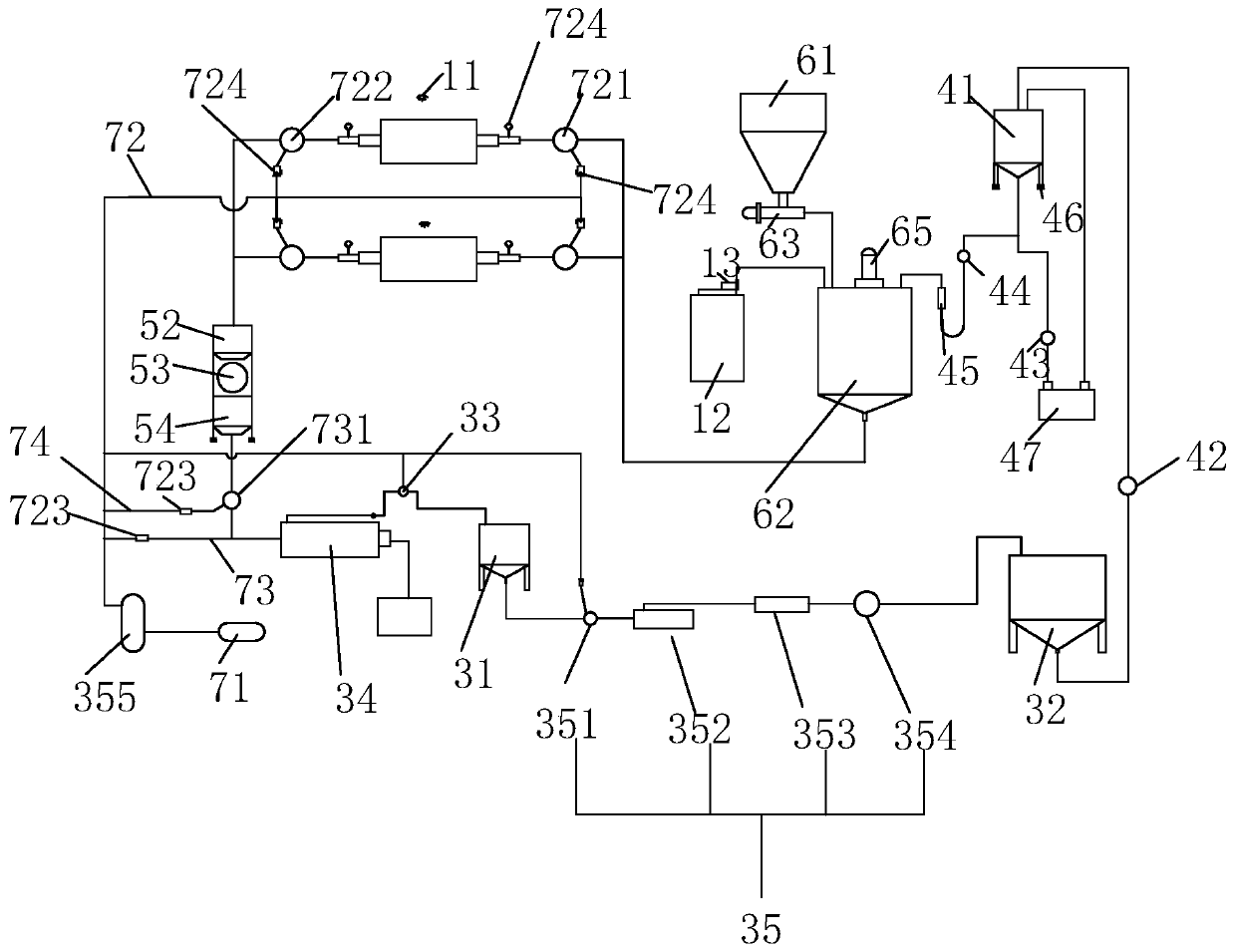

[0118] like figure 1 Shown, a kind of wet grinding metal pigment preparation system, comprises raw material supply part, ball mill part 1 and vibrating feeding part, ball mill part 1 comprises at least two ball mills, and each ball mill is all communicated with raw material supply part, and each ball mill Connected with the vibrating feeding part, each ball mill is provided with a feed pump 721 and a discharge pump 722 at both ends; the ball mill is provided with an infrared temperature detector 11, and a one-way valve 724 is provided between the ball mill and the feed pump 721. To the role of pressure.

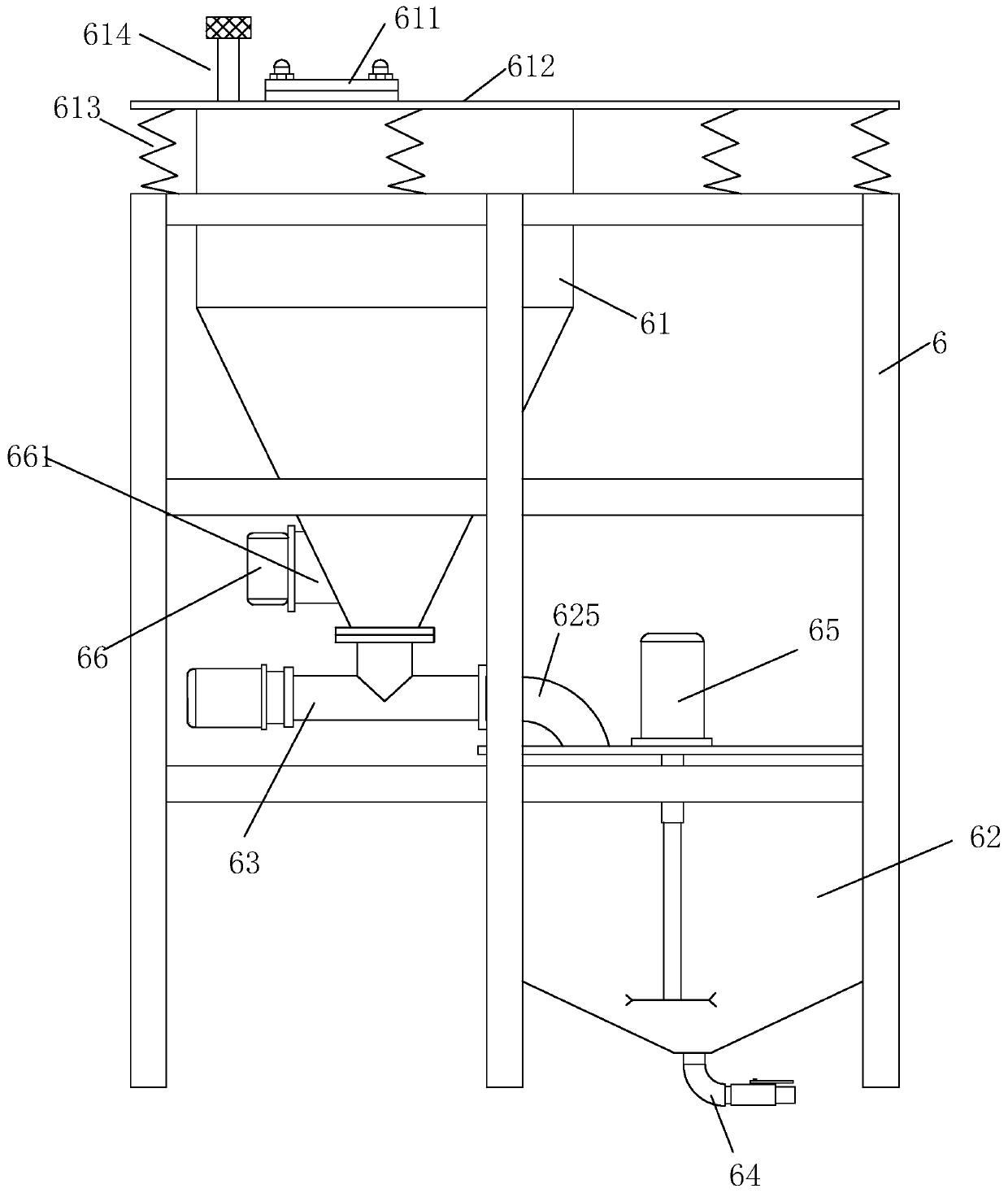

[0119] The raw material supply part includes a raw material tank 61, a mixing tank 62, an auxiliary agent tank 12 and a cold oil storage tank 41, and the mixing tank 62 communicates with each ball mill, and the raw material material tank 61, the auxiliary agent tank 12 and the cold oil storage tank 41 All are communicated with the mixing tank 62, the mixing tank 62 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com