Method for Separating Starches with Different Particle Sizes by Gravity Suspension in Polyethylene Glycol 200 Solution

A technology of polyethylene glycol and starch, which is applied in the field of food processing, can solve the problems of long separation time or poor separation effect, unfavorable water resource conservation, waste of a lot of time, etc., achieve good compatibility and excellent lubricity, and save production cost, effect of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] This embodiment is an example of the method for separating starches with different particle sizes by gravity suspension of polyethylene glycol 200 solution according to the present invention, comprising the following steps:

[0023] (1) Mix sugar palm powder with 0.25% sodium hydroxide solution to make 10% starch milk, stir it magnetically for 24 hours, wash with water three times to remove lye, and dry to obtain pure starch.

[0024] (2) Mix the pure starch obtained in step (1) with 0.25% polyethylene glycol suspension to obtain a sample suspension with a concentration of 1%.

[0025] (3) Stir the sample suspension prepared in (2) evenly, and use the gravity suspension method to separate the particles with different gravity. Separation of small particles is to be sampled once every 40 minutes. Each time, 10% volume solution of the upper layer is taken, and the suspension is filled with 2000mL, stirred evenly, naturally precipitated, and sampled, and repeated 40 times; ...

Embodiment 2

[0029] This embodiment is another example of the method for separating starches with different particle sizes by gravity suspension of polyethylene glycol 200 solution according to the present invention, which includes the following steps:

[0030] (1) Mix cornstarch with 0.25% sodium hydroxide solution to make 10% starch milk, stir magnetically for 24 hours, wash with water three times to remove lye, and dry to obtain pure starch.

[0031] (2) Take the pure starch obtained in step (1) and 0.25% polyethylene glycol suspension to obtain a 1% sample suspension.

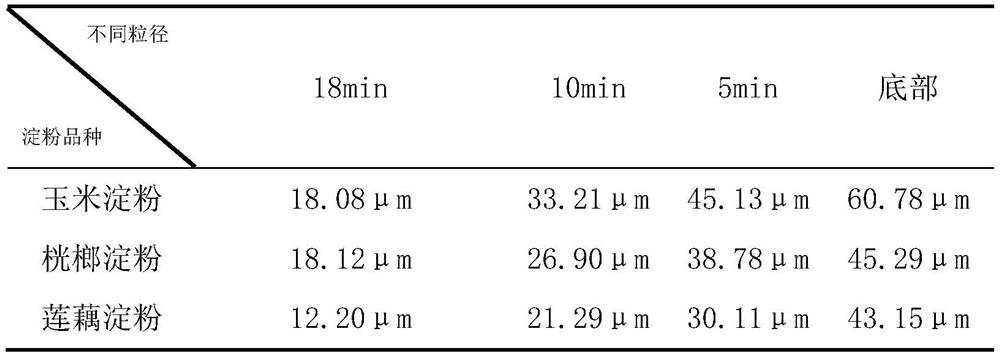

[0032] (3) Stir the sample suspension prepared in (2) evenly, and use the gravity suspension method to separate the particles with different gravity. Small particles are separated by sampling once every 40 minutes, taking 10% volume solution of the upper layer each time, filling 2000mL, stirring evenly, naturally precipitating, sampling, and repeating this 40 times; large particles are sampled once every 18 minutes, rep...

Embodiment 3

[0036] This embodiment is another example of the method for separating starches with different particle sizes by using polyethylene glycol 200 solution gravity suspension according to the present invention, comprising the following steps:

[0037] (1) Mix lotus root starch with 0.25% sodium hydroxide solution to make 10% starch milk, stir magnetically for 24 hours, wash with water three times to remove lye, and dry to obtain pure starch.

[0038] (2) Mix the pure starch obtained in step (1) with 0.25% polyethylene glycol 200 solution to obtain a sample suspension with a concentration of 1%.

[0039] (3) Stir the sample suspension prepared in (2) evenly, and use gravity suspension to separate particles of different sizes. Small particles are separated by sampling once every 40 minutes, taking 10% volume solution of the upper layer each time, filling 2000mL, stirring evenly, naturally precipitating, sampling, and repeating this 40 times; large particles are sampled once every 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com