Ester base oil with copper corrosion inhibition performance

A technology of ester base oil and copper corrosion, applied in the field of ester base oil, can solve the problems of poor solubility, achieve good technical value and application value, enhance copper corrosion inhibition performance, and excellent corrosion inhibition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

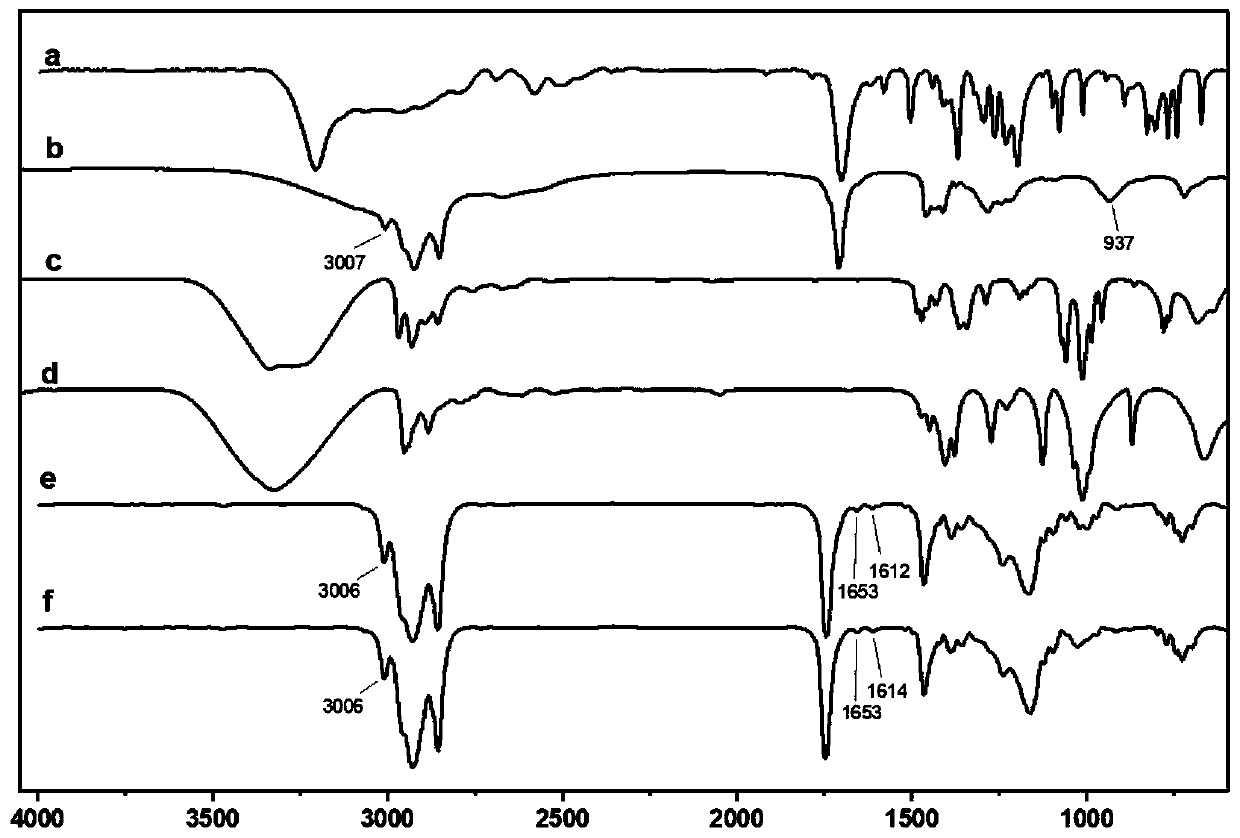

Image

Examples

Embodiment 1

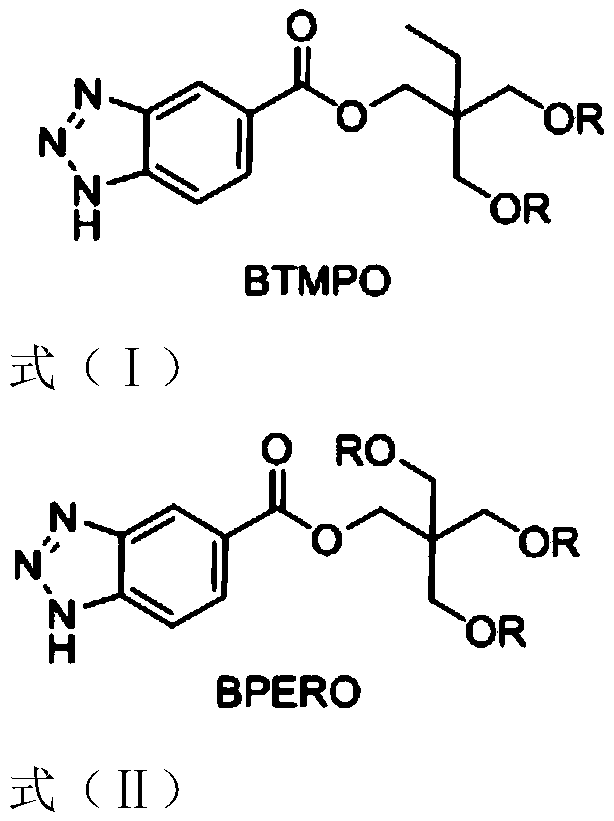

[0022] (1) 5-carboxybenzotriazole, trimethylolpropane, oleic acid are joined in the there-necked flask according to the molar ratio 0.1:1:2.9, add 2wt‰ stannous oxide as catalyst, add 20wt% xylene as With water agent, react at 210°C for 9 hours to obtain ester base oil;

[0023] (2) Add 1 wt% magnesium silicate to the ester base oil, stir at 70° C. for 1 h, then add 2 wt % diatomaceous earth, continue stirring for 1 h, and suction filter to obtain BTMPO base oil.

Embodiment 2

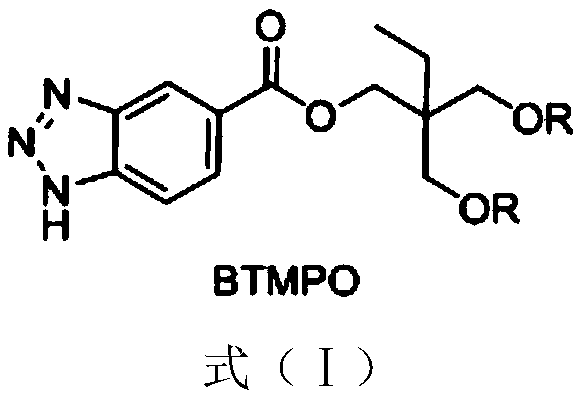

[0025] (1) 5-carboxybenzotriazole, pentaerythritol, and oleic acid are added in a three-necked flask according to a molar ratio of 0.1:1:3.9, 2wt‰ stannous oxide is added as a catalyst, and 20wt% xylene is added as a water-carrying agent, React at 210°C for 9 hours to obtain ester base oil;

[0026] (2) Add 1 wt% magnesium silicate to the crude base oil, stir at 70°C for 1 h, then add 2 wt% diatomaceous earth, continue stirring for 1 h, and suction filter to obtain BPERO base oil.

Embodiment 3

[0028] (1) 5-carboxybenzotriazole, trimethylolpropane, oleic acid are added in the there-necked flask according to the molar ratio of 0.05:1:2, 2wt‰ stannous oxide is added as a catalyst, and 20wt% xylene is added as With water agent, react at 210°C for 9 hours to obtain ester base oil;

[0029] (2) Add 1 wt% magnesium silicate to the crude base oil, stir at 70°C for 1 h, then add 2 wt% diatomaceous earth, continue stirring for 1 h, and suction filter to obtain BTMPO base oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com