Cleaning agent for polishing wax film and preparation method thereof

A cleaning agent and polishing wax technology, which is applied in the direction of detergent composition, chemical instruments and methods, non-surface active cleaning solvents, etc., can solve the problems of low cleaning efficiency and poor cleaning performance of residual wax, and achieve cleaning efficiency Improvement, excellent corrosion inhibition and anti-oxidation effect, and the effect of reducing the residue of polishing agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

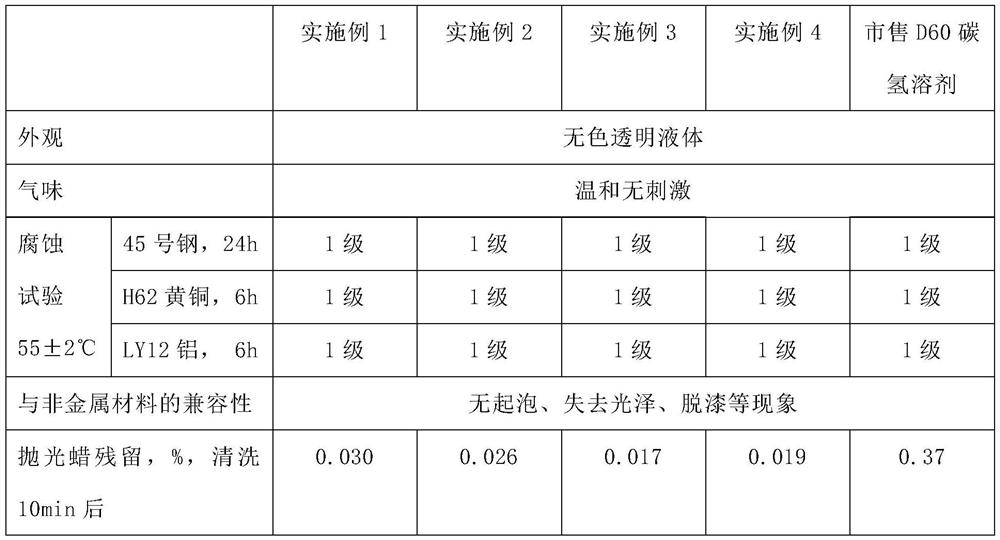

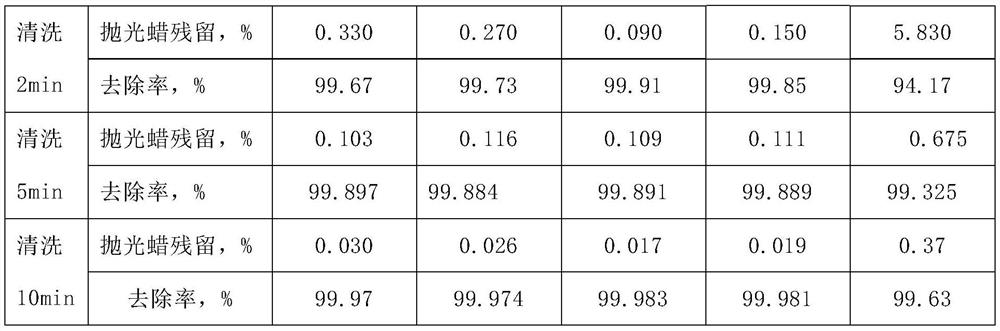

Examples

Embodiment 1

[0036] Among the embodiment 1, a cleaning agent for polishing wax film is provided, calculated by mass percentage, including the following components:

[0037] Hydrocarbon solvent (D60 dearomatized hydrocarbon solvent oil) 74.9%;

[0038] Fatty alcohol (industrial grade 1,3-butanediol) 8%;

[0039] Fatty acid ester (industrial grade dibasic acid dimethyl ester) 16%;

[0040] Benzenetriazole (industrial grade benzotriazole) 0.1%;

[0041] Stabilizer (ethylene glycol tert-butyl ether) 1%.

[0042] Under normal pressure, the benzene triazole and fatty acid ester are stirred and heated to 40-60 °C, and the dissolution is uniform and transparent;

[0043] After cooling down to room temperature, add hydrocarbon solvent, aliphatic alcohol and stabilizer and continue to stir for 10-30min to mix well and filter through 80-100 mesh screen.

Embodiment 2

[0045] Among the embodiment 2, a cleaning agent for polishing wax film is provided, calculated by mass percentage, including the following components:

[0046] Hydrocarbon solvent (D60 dearomatized hydrocarbon solvent oil) 69.9%;

[0047] Fatty alcohol (industrial grade n-butanol) 10%;

[0048] Fatty acid ester (technical grade methyl palmitoleate) 18%;

[0049] Benzenetriazole (industrial grade benzotriazole) 0.1%;

[0050] Stabilizer (diethylene glycol monobutyl ether) 2%.

[0051] Under normal pressure, the benzene triazole and fatty acid ester are stirred and heated to 40-60 °C, and the dissolution is uniform and transparent;

[0052] After cooling down to room temperature, add hydrocarbon solvent, aliphatic alcohol and stabilizer and continue to stir for 10-30min to mix well and filter through 80-100 mesh screen.

Embodiment 3

[0054] Among the embodiment 3, a cleaning agent for polishing wax film is provided, calculated by mass percentage, including the following components:

[0055] Hydrocarbon solvent (IP60 isoparaffin solvent oil) 69.5%;

[0056] Fatty alcohol (industrial grade n-butanol) 8.5%;

[0057] Fatty acid ester (industrial grade dimethyl adipate) 17%;

[0058] Benzenetriazole (industrial grade benzotriazole) 0.5%;

[0059] Stabilizer (diethylene glycol monobutyl ether) 4.5%.

[0060] Under normal pressure, the benzene triazole and fatty acid ester are stirred and heated to 40-60 °C, and the dissolution is uniform and transparent;

[0061] After cooling down to room temperature, add hydrocarbon solvent, aliphatic alcohol and stabilizer and continue to stir for 10-30min to mix well and filter through 80-100 mesh screen.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com