A superhydrophobic coating with thermal conductivity and anti-corrosion function and preparation method thereof

A super-hydrophobic coating and anti-corrosion technology, applied in anti-corrosion coatings, coatings, polyurea/polyurethane coatings, etc., can solve problems such as poor thermal conductivity and poor anti-corrosion function, and achieve excellent waterproof performance, good thermal conductivity, and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

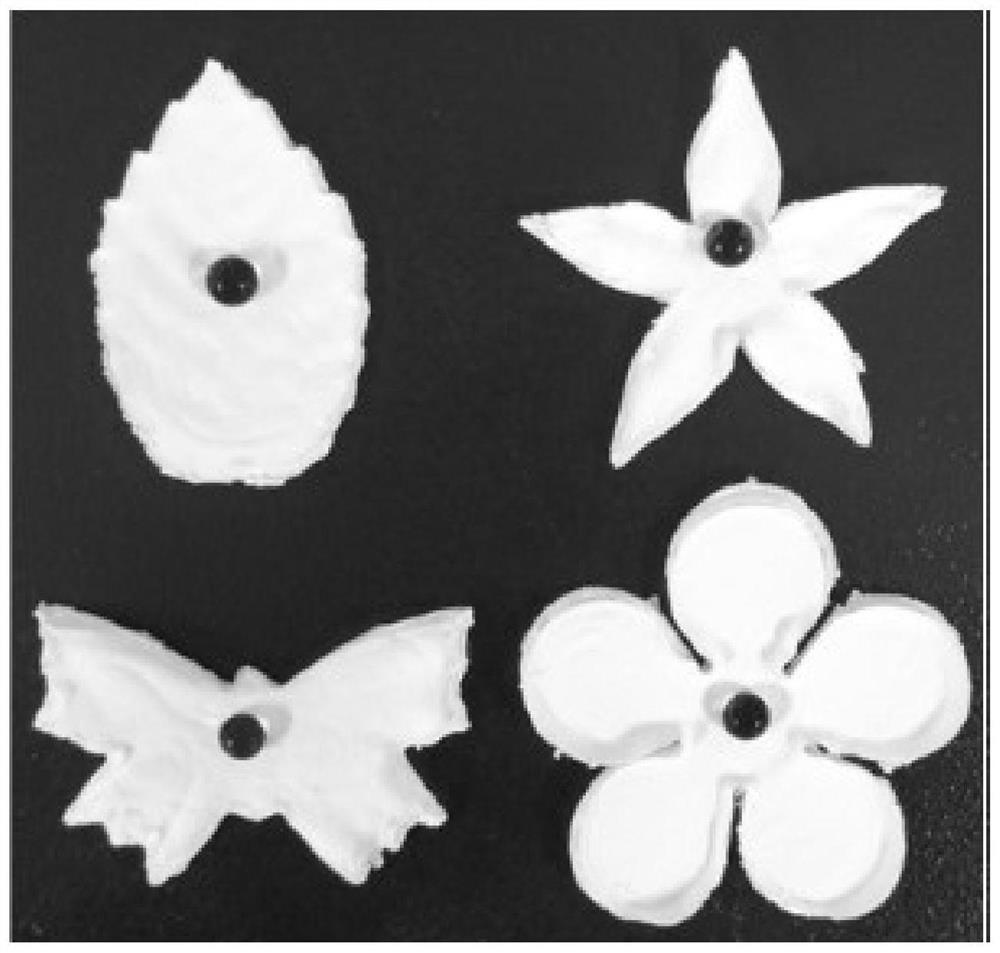

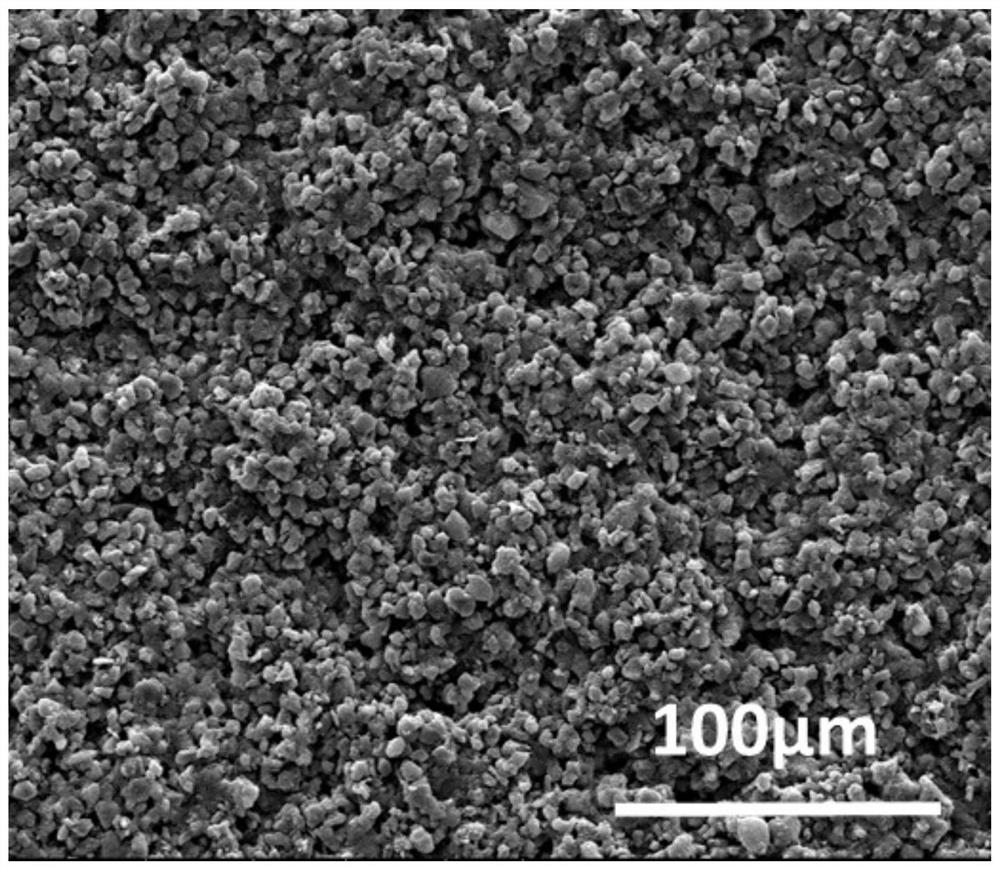

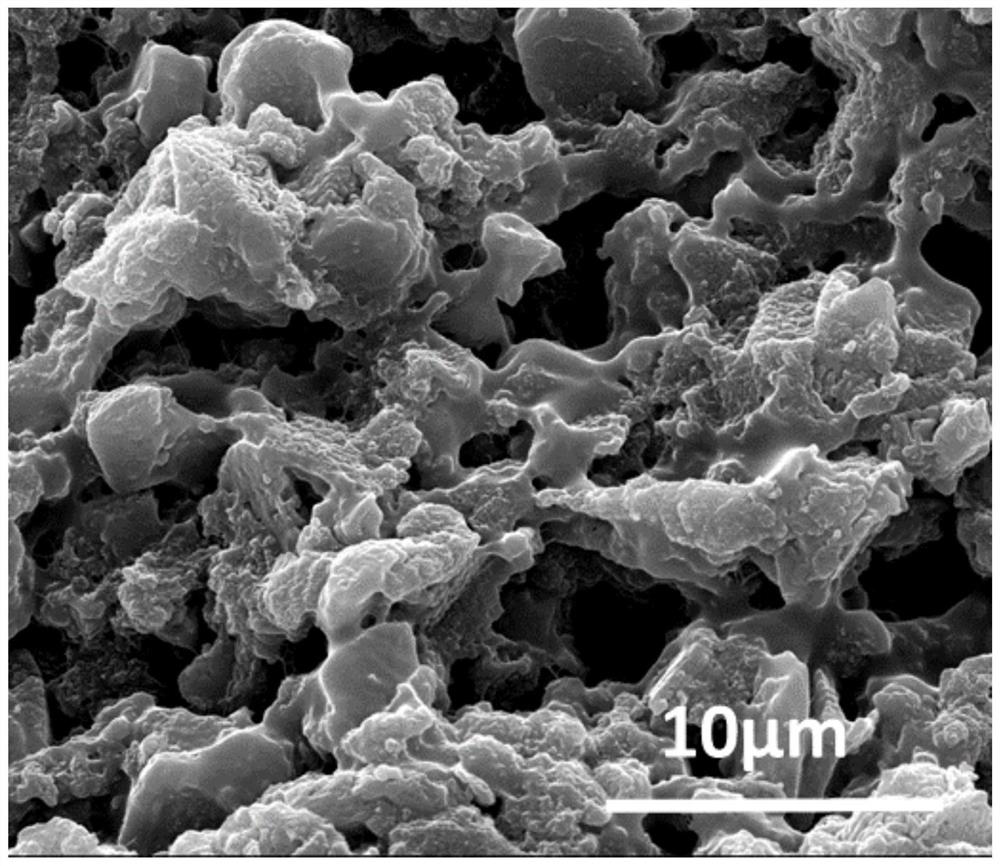

Image

Examples

Embodiment 1

[0044] Add 6g of silicone rubber (component A of 184 silicone rubber), 0.6g curing agent (component B of 184 silicone rubber), and 7g of hydrophobic alumina (nano-alumina:micron-alumina=2:5) to 16g of n-decane, and After ultrasonic dispersion and mixing for 20 minutes, a uniform suspension was obtained, which was then evenly coated on the surface of the iron sheet, and quickly placed in a 110°C oven for heating for 30 minutes.

Embodiment 2

[0046] Add 4.6g of silicone rubber (component A of 184 silicone rubber), 0.46g of curing agent (component B of 184 silicone rubber), and 7.2g of hydrophobic alumina (nano-alumina:micron-alumina=3:5) to 16g of n-decane , After ultrasonic dispersion and mixing for 20 minutes, a uniform suspension was obtained, and then evenly coated on the surface of the iron sheet, and quickly placed in a 110°C oven for heating for 30 minutes.

Embodiment 3

[0048] Add 2.5g of silicone rubber (component A of 184 silicone rubber), 0.25g of curing agent (component B of 184 silicone rubber), and 7.2g of hydrophobic alumina (nano-alumina:micron-alumina=1:5) to 18g of n-decane , After ultrasonic dispersion and mixing for 20 minutes, a uniform suspension was obtained, and then evenly coated on the surface of the iron sheet, and quickly placed in a 110°C oven for heating for 30 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com