Airflow guide plate for spinneret of melt-blown loom

A deflector and spinneret technology, applied in the direction of melt spinning, non-woven fabrics, textiles and papermaking, etc., can solve the problems of no guide tooth design, finished product level restrictions, uneven distribution of melt-blown fabric fibers, etc. To achieve the effect of enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

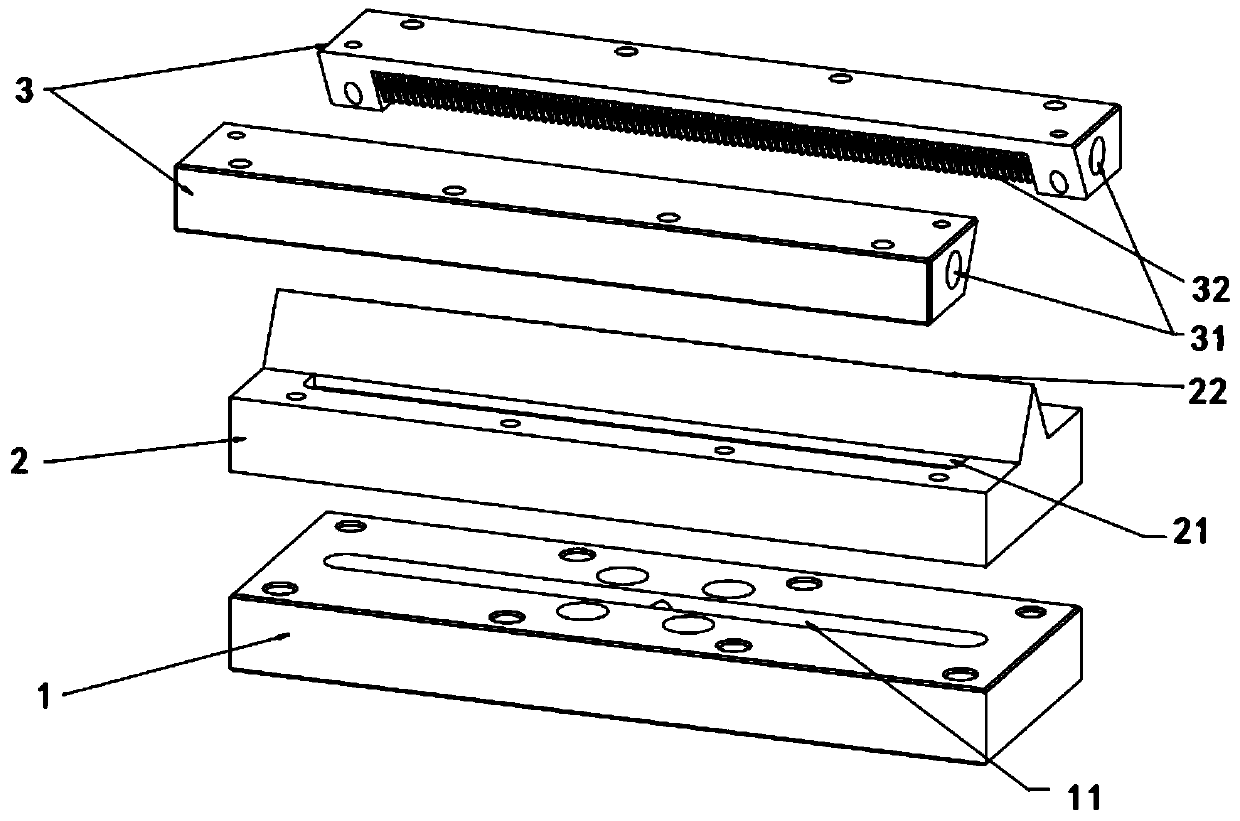

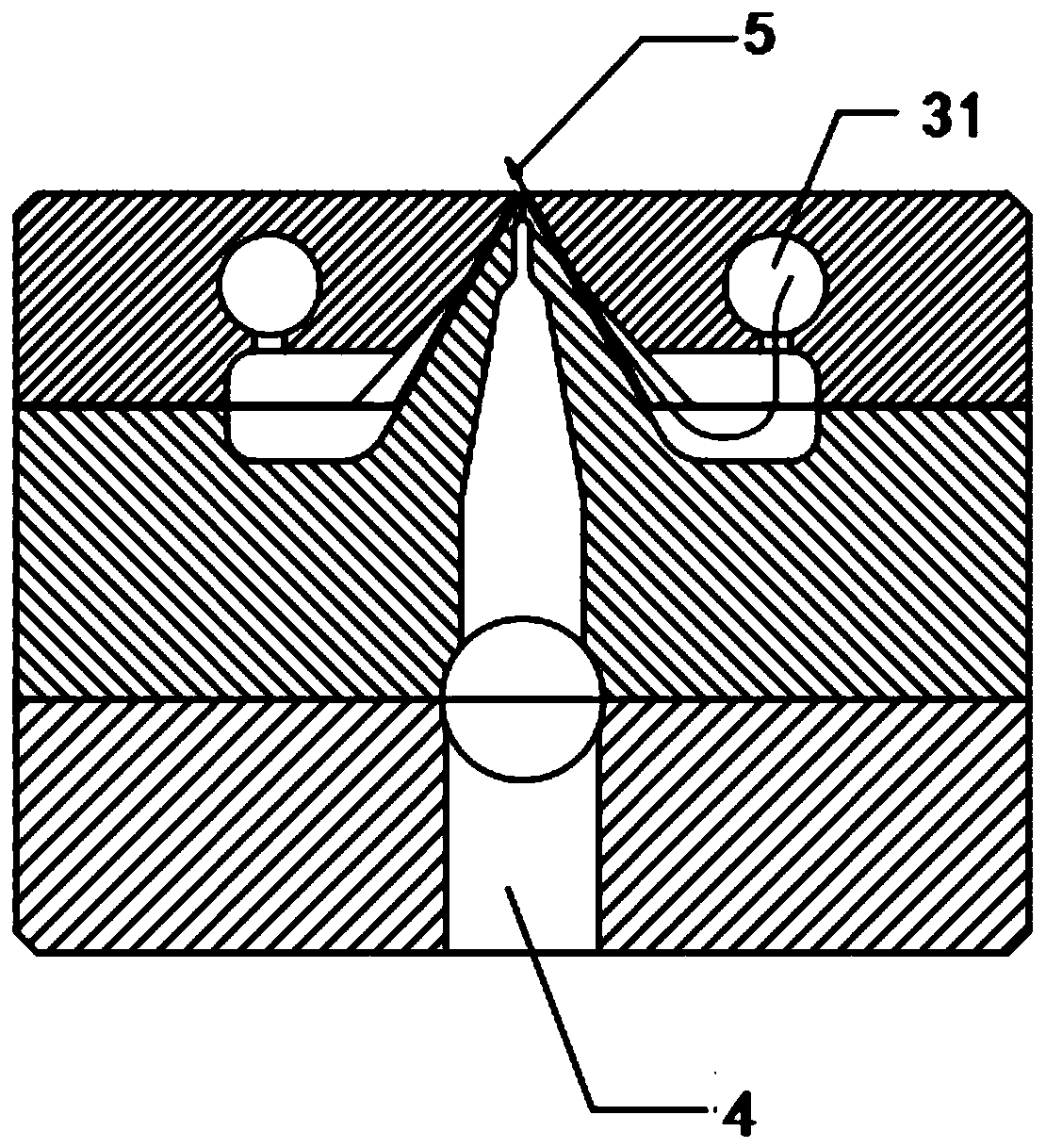

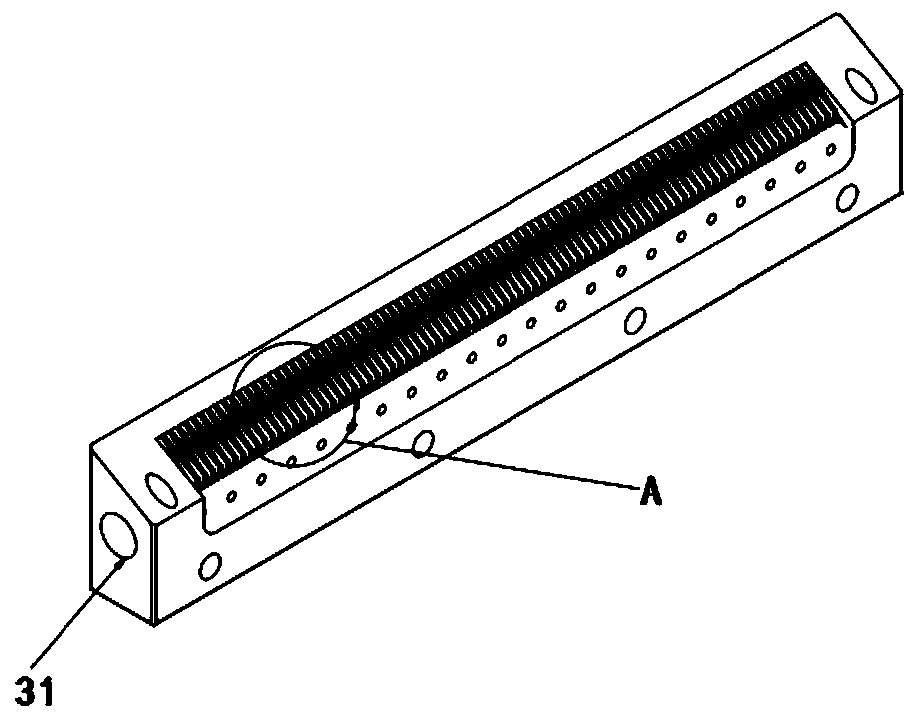

[0016] like figure 1 -As shown in Figure 5, the present invention includes a melt fluid feeding plate, a spinneret main body, and a gas jet flow plate; the melted chemical fiber raw material enters the melt channel of the spinneret main body from the heat flow groove of the melting fluid feeding plate, The spinneret hole of the spinneret main body forms a filamentary outflow; the high-temperature and high-pressure gas enters the air cavity formed by the spinneret main body and the gas jet plate from the air inlet of the gas jet plate; and then flows from the air cavity to the gas jet The diversion groove of the plate moves, and the gas is ejected under pressure to form a symmetrical high-speed airflow with a certain angle with the spinneret hole of the spinneret main body, thereby pulling the chemical fiber melt ejected from the spinneret main spinneret hole to form microfibers.

[0017] A further design is that: the airflow deflector is made of SUS431, SUS630, SUS440C, S136H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com