An integral prefabrication method for the working layer of a refiring kiln

A technology of overall prefabrication and working layer, applied in furnaces, lighting and heating equipment, lining repair, etc., can solve the problems of high ramming material strength, high erosion resistance, affecting the service life of the kiln, brick expansion or kiln skin corrosion, etc. Achieve the effect of improving the repair efficiency, improving the economic benefits of the enterprise, and improving the life of the furnace lining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

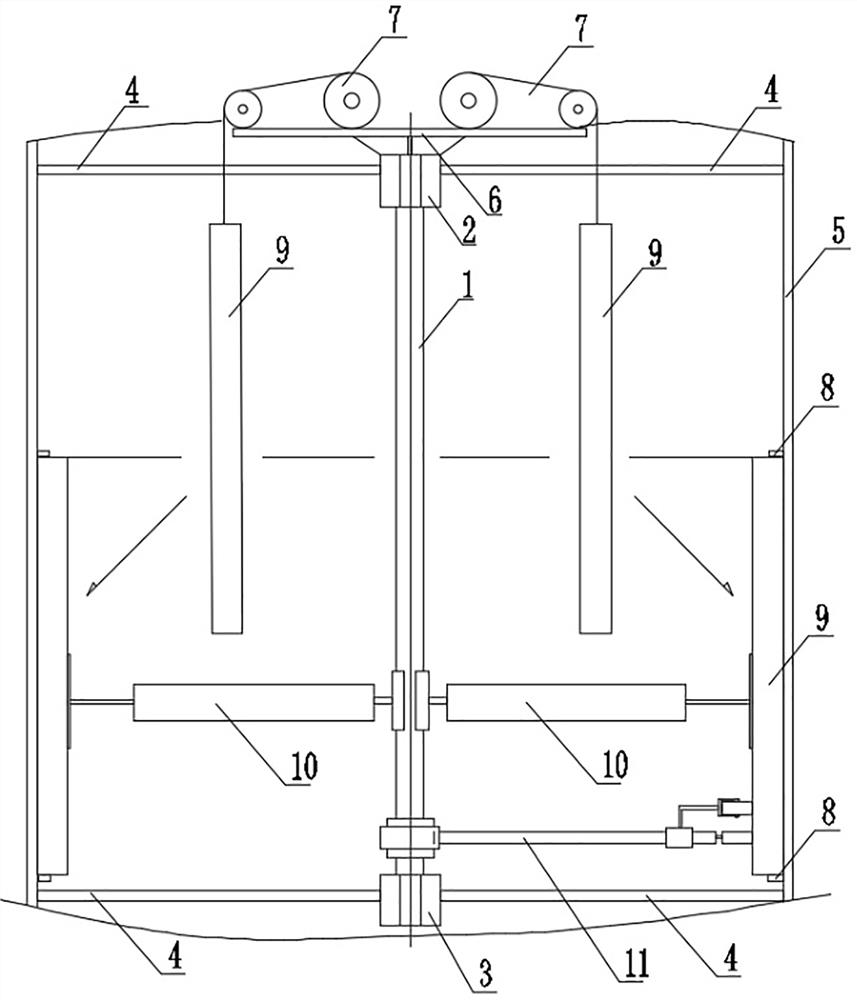

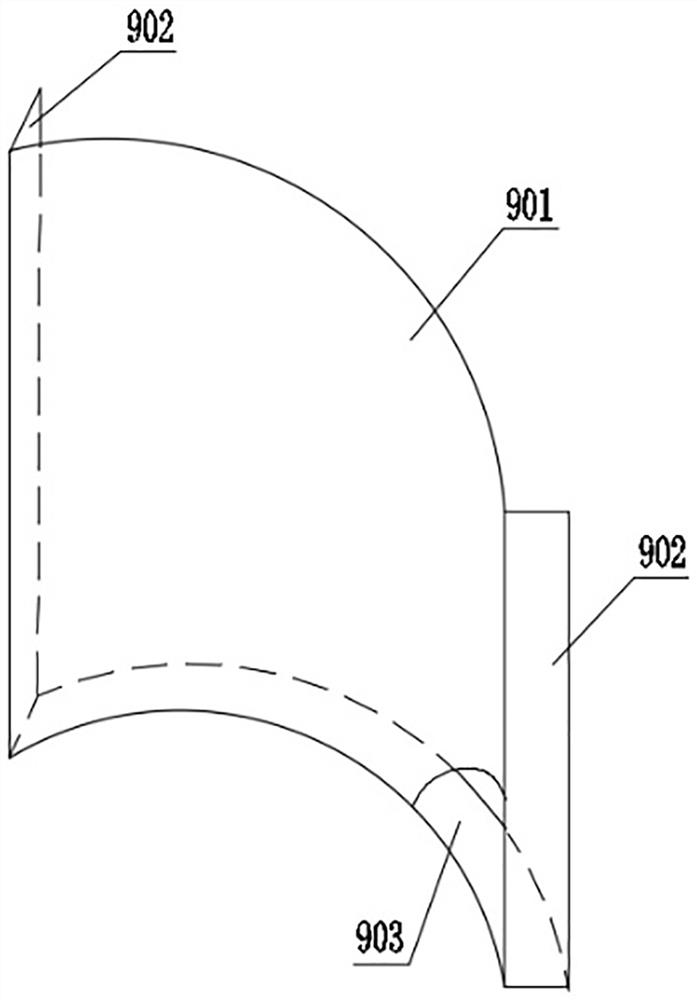

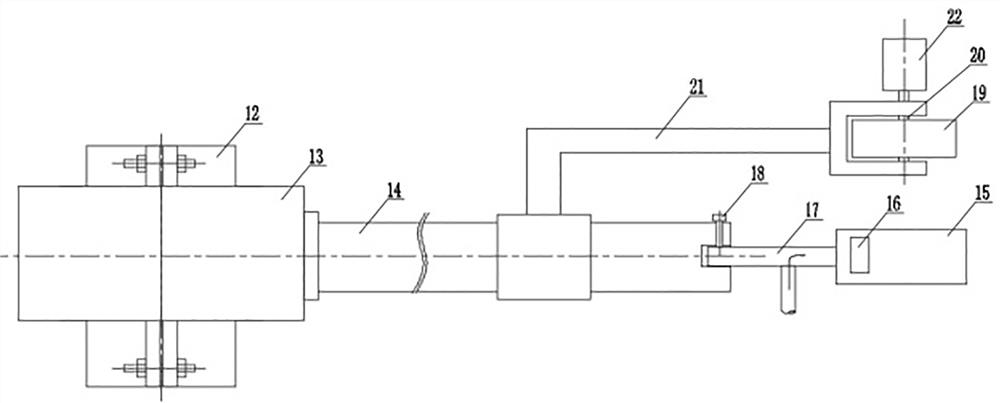

[0025] See Figure 1-Figure 3 , which is a structural schematic diagram of an embodiment of the overall prefabrication method for the working layer of a refiring kiln according to the present invention. The area on the surface of the kiln body that needs to be prefabricated for the working layer is evenly divided according to the circumferential direction to make a partition template. The lining of the kiln body is made of the following The above-mentioned sequence is formed, and the specific operation steps are as follows: 1) Lifting frame positioning, setting the lifting frame 1 in the center of the kiln body, the top column head 2 and the bottom column foot 3 of the lifting frame are fixed by spot welding with multiple cross arms 4 and kiln skin 5, The hoisting frame 6 is arranged on the top of the lifting frame 1, and a plurality of hoisting m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com