Hybrid sensor based on vernier effect of parallel structure and manufacturing method thereof

A technology of vernier effect and manufacturing method, which is applied in the direction of converting sensor output, using optical devices to transmit sensing components, instruments, etc., can solve problems such as temperature cross sensitivity and complex structure manufacturing, and achieve improved sensitivity and stability, improved sensitivity, Highly stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below through examples, and the following examples are explanations of the present invention and the present invention is not limited to the following examples.

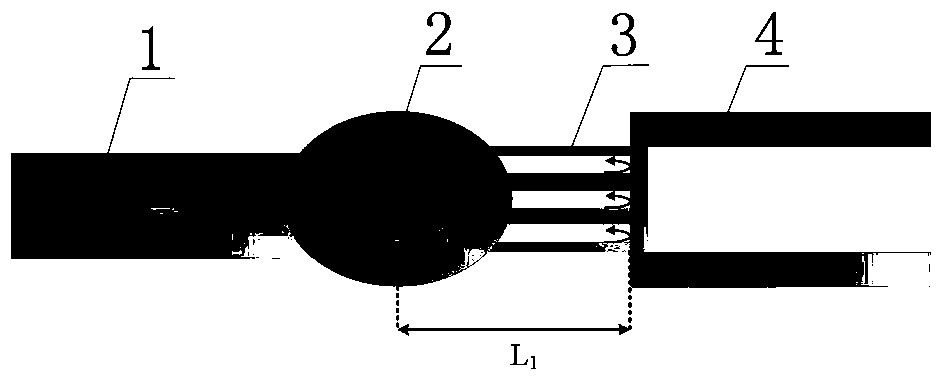

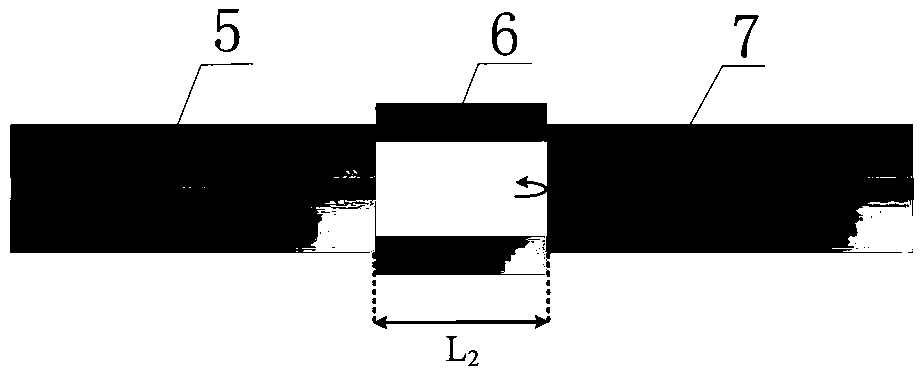

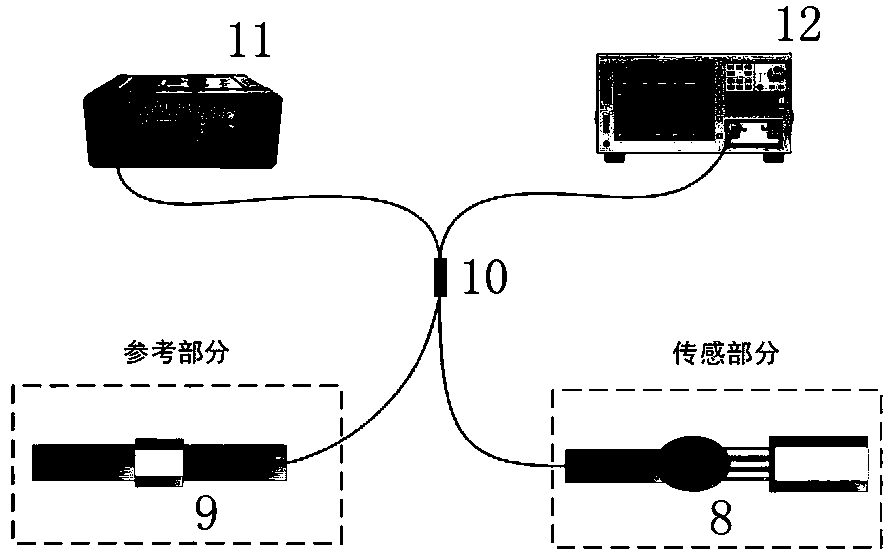

[0036] like figure 1 and figure 2 As shown, a kind of hybrid sensor based on parallel structure vernier effect of the present invention comprises Michelson interferometer and Fabry-Perot interferometer arranged in parallel, and Michelson interferometer comprises single-mode optical fiber a1, spherical structure arranged in sequence along the optical fiber transmission direction 2. Special optical fiber PCF3 and silica microtube a4, one end of single-mode optical fiber a1 is fixedly connected to one side of spherical structure 2, the other side of spherical structure 2 is fixedly connected to one end of special optical fiber PCF3, silica microtube One end of the tube a4 is sheathed outside the other end of the special optical fiber PCF3 and is fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com