Control method and device of permanent magnet synchronous motor and related assembly

A technology of permanent magnet synchronous motor and control method, which is applied in the direction of motor control, motor generator control, AC motor control, etc., can solve the problems of increasing hardware cost, burning brake resistance, high hardware cost, etc., and achieve improved stability and robustness performance, inhibit bus voltage rise, and ensure the effect of bus voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

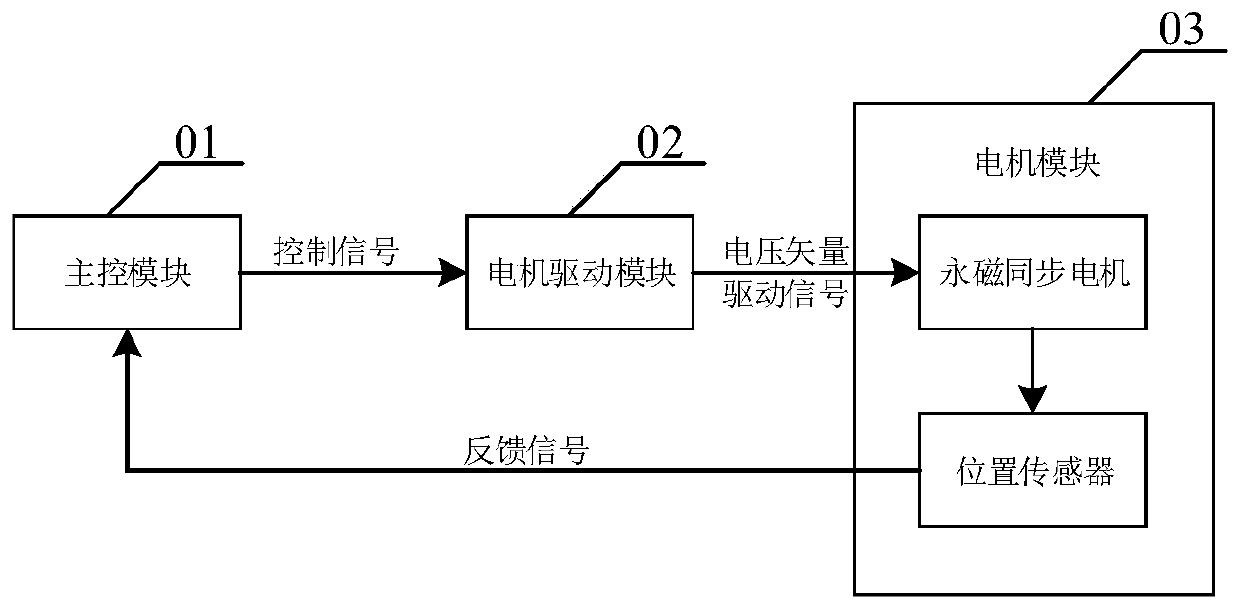

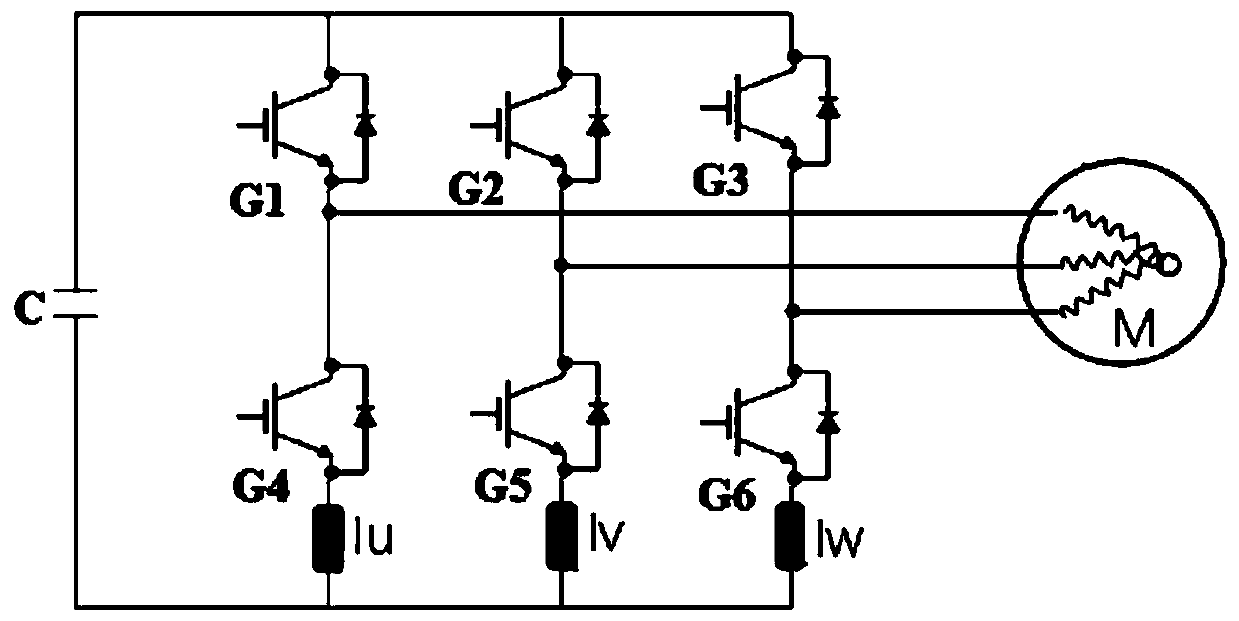

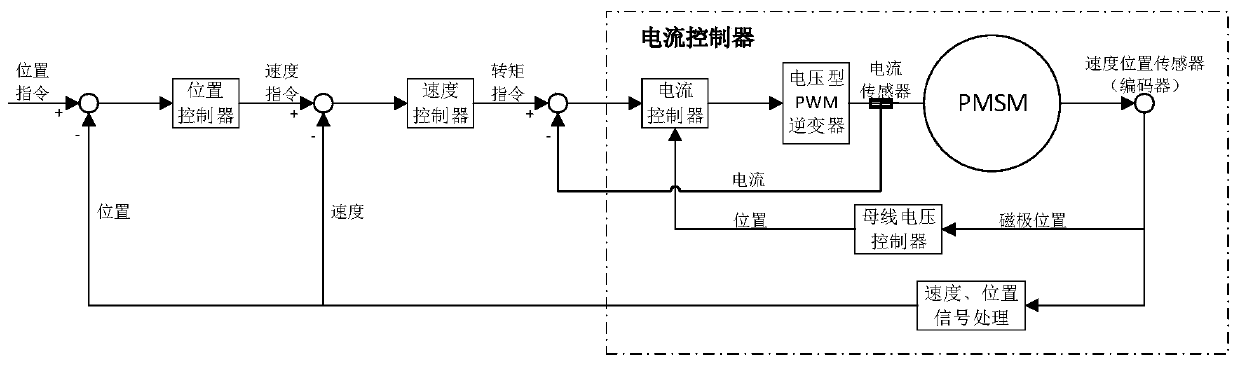

[0042] The core of this application is to provide a control method, device, electronic equipment and computer-readable storage medium for a permanent magnet synchronous motor. The software control scheme can effectively suppress the rise of the bus voltage when the motor is braking, and ensure the stability of the bus voltage. It can avoid the problem of affecting the braking control effect when the moment of inertia is too large, and ensure that fast braking can be achieved under any conditions, improving the stability and robustness of the system.

[0043] In order to make the purposes, technical solutions and advantages of the embodiments of the present application clearer, the technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the drawings in the embodiments of the present application. Obviously, the described embodiments It is a part of the embodiments of this application, not all of them. B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com