Ethyl cellulose taste-masking microsphere with controllable drug release speed and preparation thereof

A technology of ethyl cellulose and microspheres, applied in the field of pharmacy, to achieve the effects of easy swallowing, high dosage flexibility, and controllable drug release rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

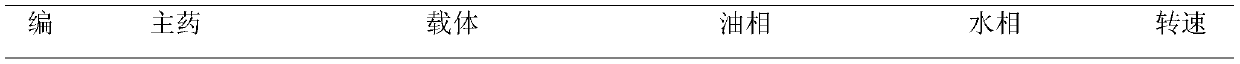

[0036] Example 1: The preparation method of ethyl cellulose microspheres is: take the carrier ethyl cellulose and dissolve it in a corresponding solvent, then add a certain amount of medicine to dissolve completely to obtain an oil phase, and drop the above oil phase into the mixture containing In the surfactant water phase, after emulsification and stirring, suction filtration, washing the product with deionized water, and drying to obtain ethyl cellulose microspheres. The dosage and conditions for the preparation of ethylcellulose microspheres of different drugs are shown in Table 1.

[0037] Table 1 Preparation conditions of ethylcellulose microspheres

[0038]

[0039]

Embodiment 2

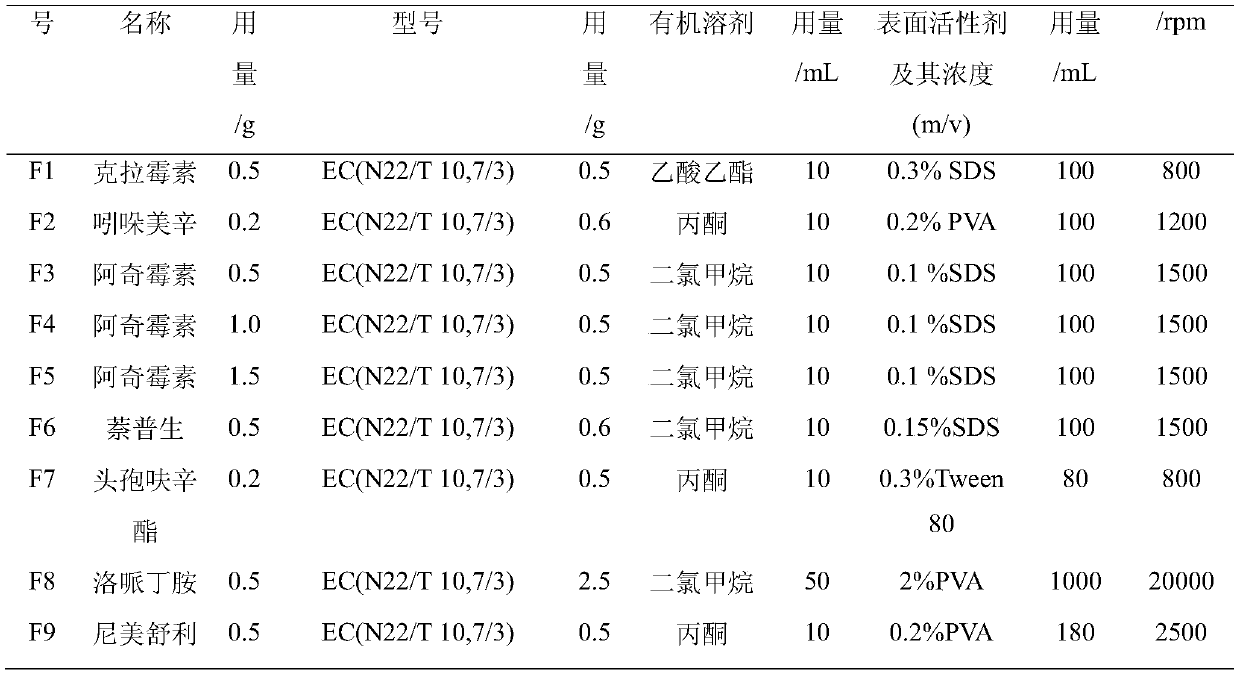

[0040] Example 2: Take the ethylcellulose microspheres in Example 1, and measure their drug loading under corresponding detection methods. The detection methods and results are shown in Table 2, wherein the HPLC flow rate is 1mL / min.

[0041] Table 2 Detection method and drug loading capacity of ethyl cellulose microspheres

[0042]

Embodiment 3

[0043] Embodiment 3: Take the ethyl cellulose microsphere in embodiment 1 and add appropriate amount into drinking water to prepare as a sample that can be tasted. A group of 11 healthy adult volunteers aged 19-25 conducted a bitterness evaluation test, in which the corresponding API was used as a bitterness control. Volunteers were required to rinse their mouths with purified water, take an appropriate amount of samples and put them in their mouths, and turn their tongues back and forth until the solution was in full contact with the tongue coating. After 30 seconds, spit it out and rinsed their mouths with purified water several times. The volunteers’ opinions on the bitterness of AZI solutions with different concentrations were scored according to the bitterness scale, which consisted of four standards: 0=no taste, 1=slightly bitter, 2=medium bitterness and 3=strong bitterness.

[0044] Table 3 Evaluation of the bitterness of ethyl cellulose microspheres

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com