Stirring and gluing device with simple structure for double-component quick-drying glue

A simple structure, two-component technology, applied to mixers with rotating stirring devices, devices for coating liquid on the surface, dissolving, etc., can solve the problems of wasting rubber materials, affecting the use of glue, and high cost, and achieve extended use Long life, good mixing effect and wide glue path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

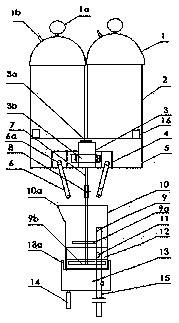

[0067] like figure 1 As shown, the storage barrel 2 containing components A and B is provided with a barometer 1a and a pipeline 1b communicating with the air compressor air storage tank on the barrel cover 1 to maintain a constant pressure so that the glue flow and glue output are stable. , the discharge pipes on the two storage buckets 2 are respectively connected with the inlet ends of the double-pipe feed valve 4, and the outlet end 6a of the double-pipe feed valve 4 passes through the plate surface 5 supported by the support frame 16 and is respectively connected with the two pipes. The conduit 6 is plugged. A micro-motor 3 is arranged between the two conduits 6, which is fixed on the plate surface 5 by the iron sheet 3a and the holding iron 3b, and the rotating shaft 7 at the lower end of the motor 3 is connected to the stirring rod 9 through an adjustable coupling 8, The lower end of the stirring rod has a hinged blade 9a with a smaller rotation radius at a higher posi...

Embodiment 2

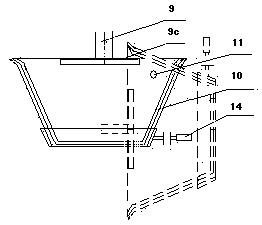

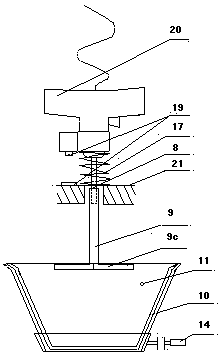

[0069] like figure 2 As shown in the figure, the two-component rubber material that flows out of the self-pressure AB storage tank according to a certain proportion and quantitatively flows through the respective pipelines through the double-pipe feed valve fixed on the operating platform at a lower position, and the double-pipe feed The outlet end of the valve is sleeved with a conduit, and the distance between the two outlets of the conduit is such that it can completely flow into the wide-mouth rubber nozzle. A motor is fixed directly above the wide-mouth rubber nozzle 10 through a support frame, and there is a rotating shaft with a taper at the lower end. The wide-mouth rubber nozzle 10 with the side wall whose mouth diameter is larger than the height and has an inclination of 25~45 degrees can also use its taper to stack several identical wide-mouth rubber nozzles in order to replace the innermost layer if necessary. A shaft pin 11 is set near the opposite side and the ...

Embodiment 3

[0071] The wide-mouth rubber nozzle 10 in the present invention can also be connected with the rotating shaft 11 or other turning mechanisms through the extension structure, so that the wide-mouth rubber nozzle 10 can be easily installed and disassembled; the shaft pin 11 can also be directly or indirectly fixed with the wide-mouth rubber nozzle. Thus, the reversal is realized by controlling the rotation of the rotating shaft 11; the sliding block 13 can also be detachably connected with the wide mouth rubber nozzle 10, and the control part 14 of the sliding block 13 is connected with the inversion mechanism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com