A pipe joint rolling connection forming tool and rolling connection process based on high filling rate

A technology for forming tooling and pipe joints, applied in storage devices, feeding devices, manufacturing tools, etc., can solve problems such as broken pipes or oil leakage, failure to seal, oil leakage, etc., to improve rolling quality and ensure Slowness, the effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

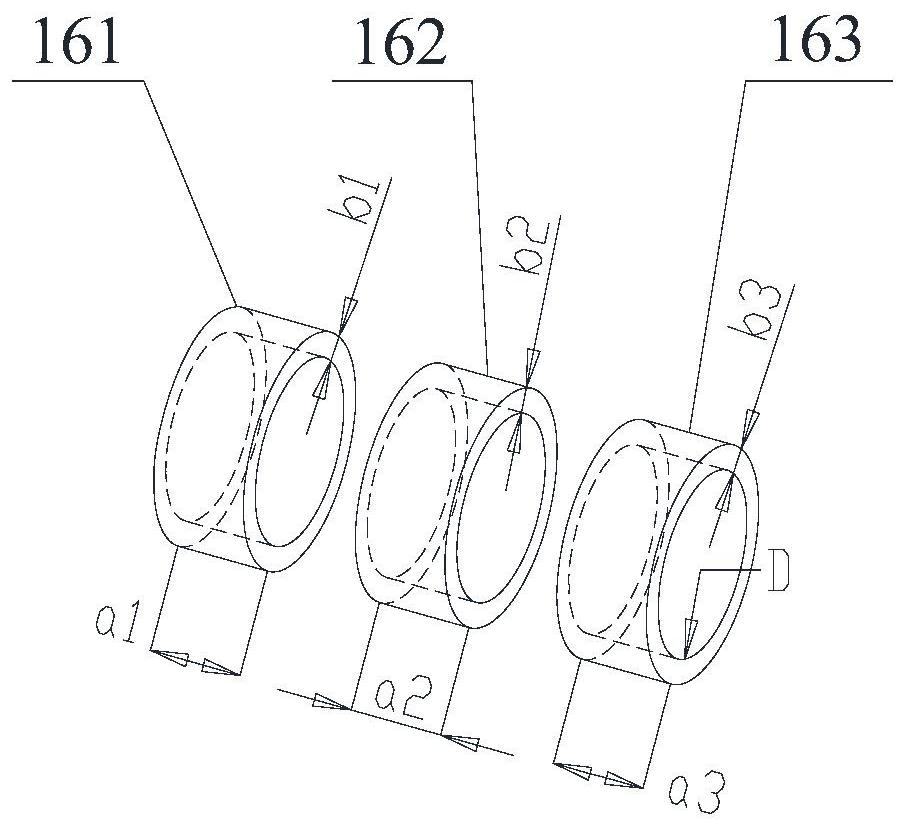

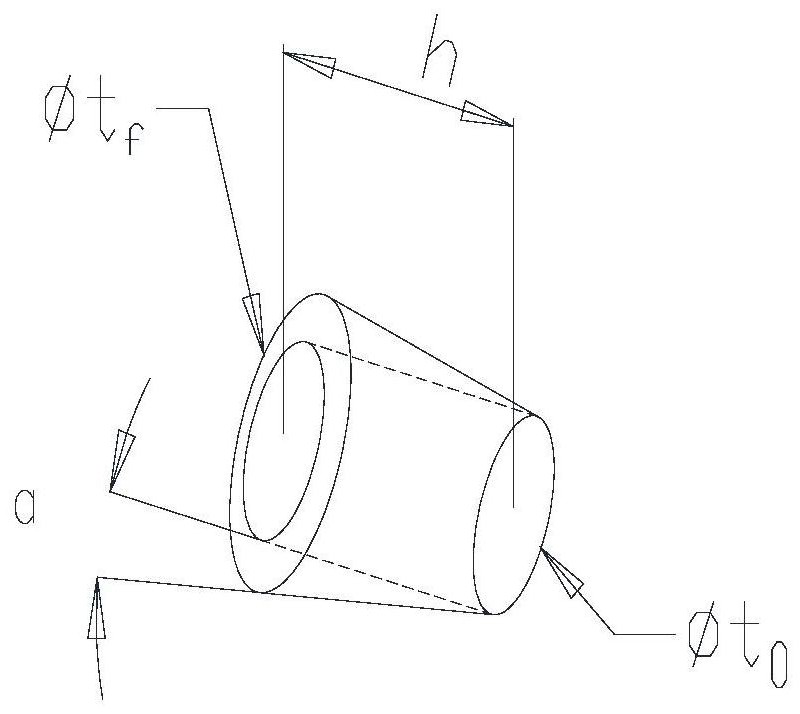

[0091] The filling volume of pipe joint groove material V=π*a1*b1*(D+b1)+π*a2*b2*(D+b2)+π*a3*b3*(D+b3); the pressure of conduit material Inlet volume W=π*D*h*sinα(D+h*sinα) / 2, in accordance with the requirements of the taper and thinning rate of the working end of the mandrel 1, make W>V, select a suitable t f make shear thinning ф t Between 15% and 40%, in order to obtain the maximum rolling area and meet the requirements of high filling rate, h (the effective length of the needle roller) is approximately equal to the length of the pipe joint, and the diameter of the needle roller is approximately equal to t 0 / 3, mandrel taper is 2α. The above rolling forming process can provide a theoretical basis for rolling processing and optimize process parameters.

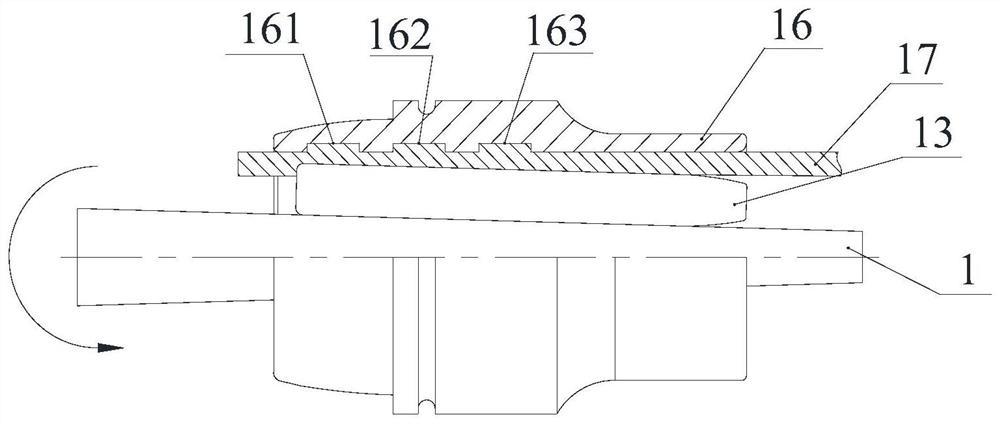

[0092] The material of pipe sleeve 16 is stainless steel 15-5PH, and the material of metal conduit 17 is titanium alloy Ti-3Al-2.5V, which is rolled and formed. The relevant material parameters of pipe sleeve 16 and metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com