Liquid nitrogen nail gun device

A nail gun and liquid nitrogen technology, applied in nailing tools, U-shaped nail tools, manufacturing tools, etc., can solve the problems of high power consumption, unsafe nail guns, etc., achieve simple structure and eliminate potential safety hazards , Solve the effect of large power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

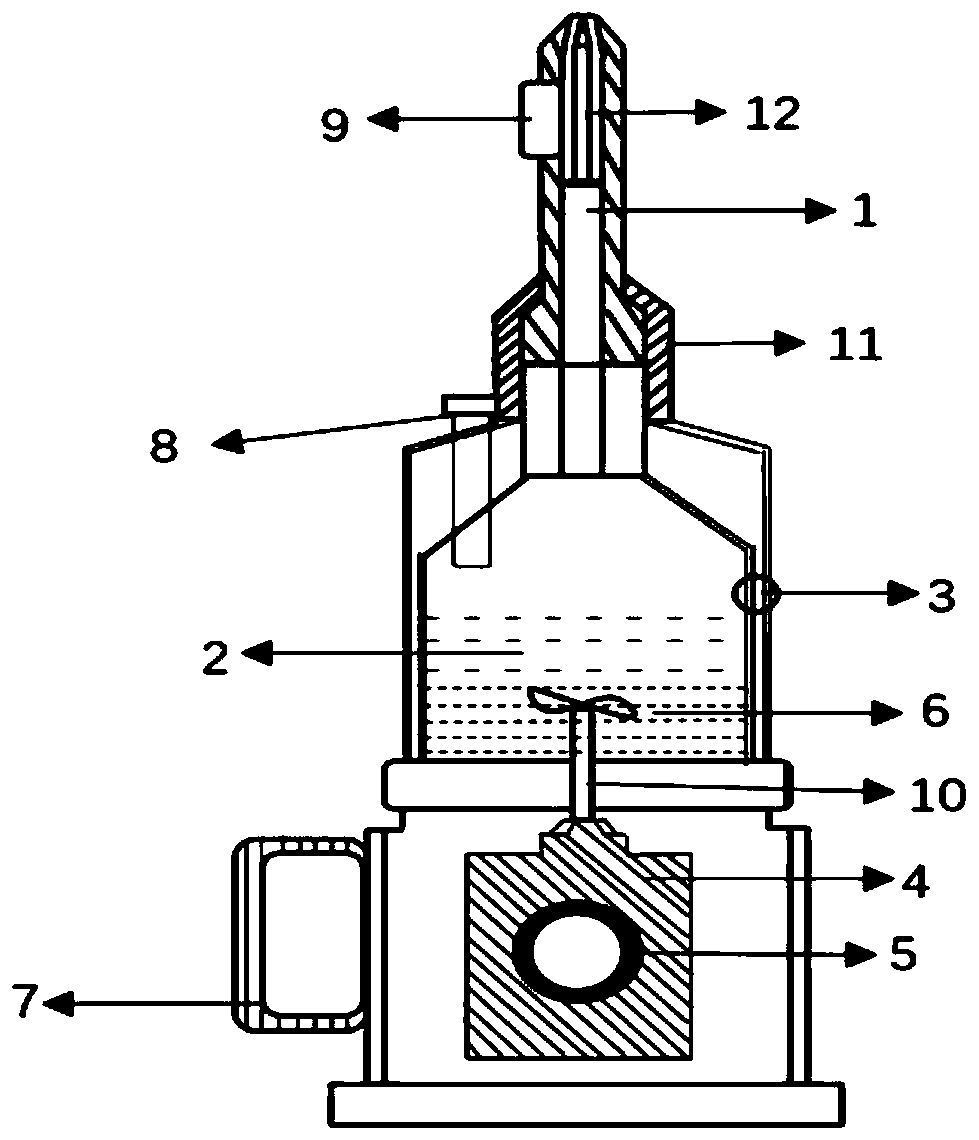

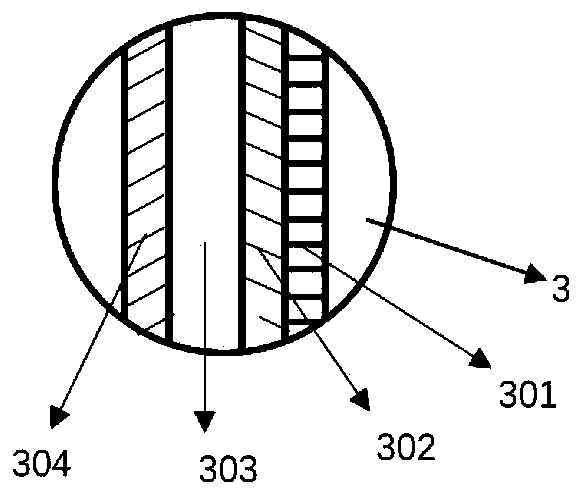

[0030] Please refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , Embodiment 1 of the present invention provides a liquid nitrogen nail gun. The gun body itself includes a barrel 1, a gasification chamber 2, a gasification chamber wall 3, a motor 4, a motor switch 5, a fan blade 6, a handle 7, a liquid inlet Port 8 and magnet 9, metal bearing 10, axle sleeve 11 and nail 12. The gun barrel 1 is arranged above the gasification chamber 2, and the lower end of the gun barrel 1 is connected to the upper port of the gasification chamber 2 through a shaft sleeve 11. The matching stepped card slot has an internal thread structure at the other end, through which the internal thread mechanism is connected with the external thread on the upper port of the gasification chamber. The entire barrel structure is simple and easy to disassemble. The nail 12 is placed in the gun barrel, and the nail is absorbed by the magnet 9 installed on one side of the gun barrel to prev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com