Polyurethane transparent primer as well as preparation method and construction method thereof

A transparent primer and polyurethane technology, applied in polyurea/polyurethane coatings, primers, coatings, etc., can solve the problems of affecting the appearance of furniture, poor filling, furniture sinking, etc., to maintain aesthetics, reduce the use of paint, The effect of reducing the number of spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

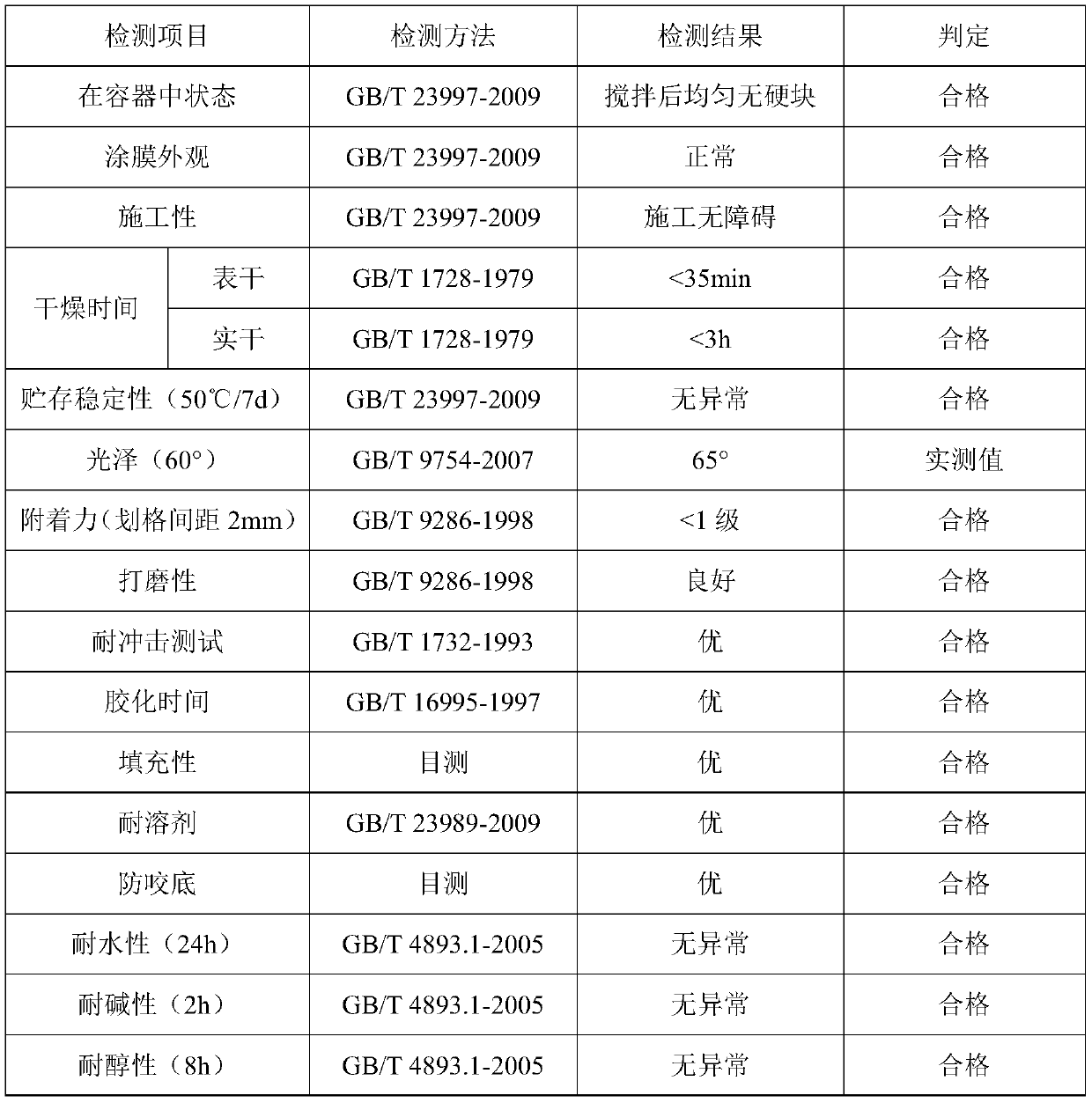

Examples

preparation example Construction

[0050] The second aspect of the present invention provides a preparation method of the polyurethane transparent primer, the steps at least include: mixing the base resin, additives, fillers, particle powder, and the first solvent to obtain component A; Mix the isocyanate curing agent and the second solvent to obtain component B.

[0051] In some preferred embodiments, (1) mix the base resin and additives evenly, continue to add fillers and mix evenly, then add particle powder to disperse evenly, and finally add the first solvent and mix evenly to obtain component A; Add the curing agent to the second solvent, add it while stirring, and mix evenly to obtain component B.

[0052] The third aspect of the present invention provides a construction method of the polyurethane transparent primer, the steps include: adding component A and component B into the container according to the proportion and stirring evenly, and then adding an appropriate amount of diluent to dilute , adjuste...

Embodiment 1

[0055] A polyurethane transparent primer, comprising A component and B component; the weight ratio between the A component and the B component is 1:0.5; wherein, the A component, by weight percentage, is made of : 60% base resin, 5% particle powder, 5% first solvent, 2% additives, and fillers to make up the balance; the raw materials of the B component are: isocyanate curing agent and second solvent; the isocyanate curing The weight ratio between solvent and second solvent is 5:1.

[0056] The base resin is an alkyd resin selected from TP3870.

[0057] The particle powder is Spanger sand flour L-40; the material of the filler is silicon micropowder, and the average particle diameter of the filler is 1250 mesh.

[0058] The first solvent is ethyl acetate.

[0059] The auxiliary agent is a combination of defoamer and dispersant, and the weight ratio of the defoamer and dispersant is 1:1.

[0060] The isocyanate curing agent is a combination of TDI adducts and TDI trimers. Th...

Embodiment 2

[0066] A polyurethane transparent primer, comprising A component and B component; the weight ratio between the A component and the B component is 1:0.4; wherein, the A component, by weight percentage, is made of : 55% base resin, 2% granule powder, 2% first solvent, 1% additives, fillers to make up the balance; the raw materials of the B component are: isocyanate curing agent, the second solvent; the isocyanate curing The weight ratio between solvent and second solvent is 4:1.

[0067] The base resin is an alkyd resin selected from TP3180.

[0068] The particle powder is Spanger sand flour L-30; the material of the filler is silicon micropowder, and the average particle diameter of the filler is 600 mesh.

[0069] The first solvent is butyl acetate.

[0070] The auxiliary agent is a combination of defoamer and dispersant, and the weight ratio of the defoamer and dispersant is 1:0.5.

[0071] The isocyanate curing agent is a combination of TDI adducts and TDI trimers. The w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com