Operation method of multistage oil-water separation tank of intelligent pulse electrostatic coalescence electrode

An oil-water separation tank and electrostatic coalescence technology, applied in the direction of electric/magnetic refining, etc., can solve the problems of increased operation and maintenance costs, poor properties, and increased floor space, so as to reduce sewage treatment costs and environmental protection pressure, Reduce the number of equipment stages and equipment, and reduce the effect of operation and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

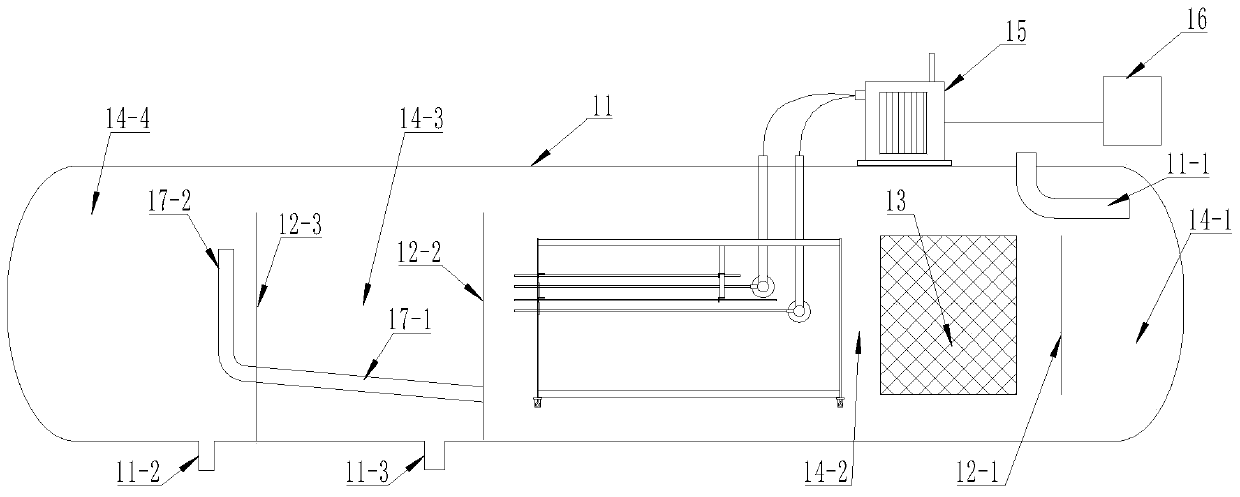

[0036] A transformer 15 is installed on the upper side of the tank body 11, and there is a wire between the transformer 15 and the controller 16. The steady flow orifice plate 12-1, the oil weir plate 12-2, and the water weir plate 12 are arranged in the tank body 11 from right to left. -3, there is a gap between the steady flow orifice 12-1 and the top and bottom of the tank body 11, and there is a gap between the oil weir plate 12-2 and the water weir plate 12-3 and the top of the tank body 11, A steady flow chamber 14-1 is formed between the steady flow orifice 12-1 and the right end of the tank body 11, the top of the tank body 11 corresponds to the steady flow chamber 14-1, and a crude oil inlet pipe 11-1 is arranged, and the steady flow orifice 12-1 and the oil An oil-water separation chamber 14-2 is formed between the weir plates 12-2, an oil chamber 14-3 is formed between the oil weir plate 12-2 and the water weir plate 12-3, and an oil discharge pipe is provided at the...

Embodiment 2

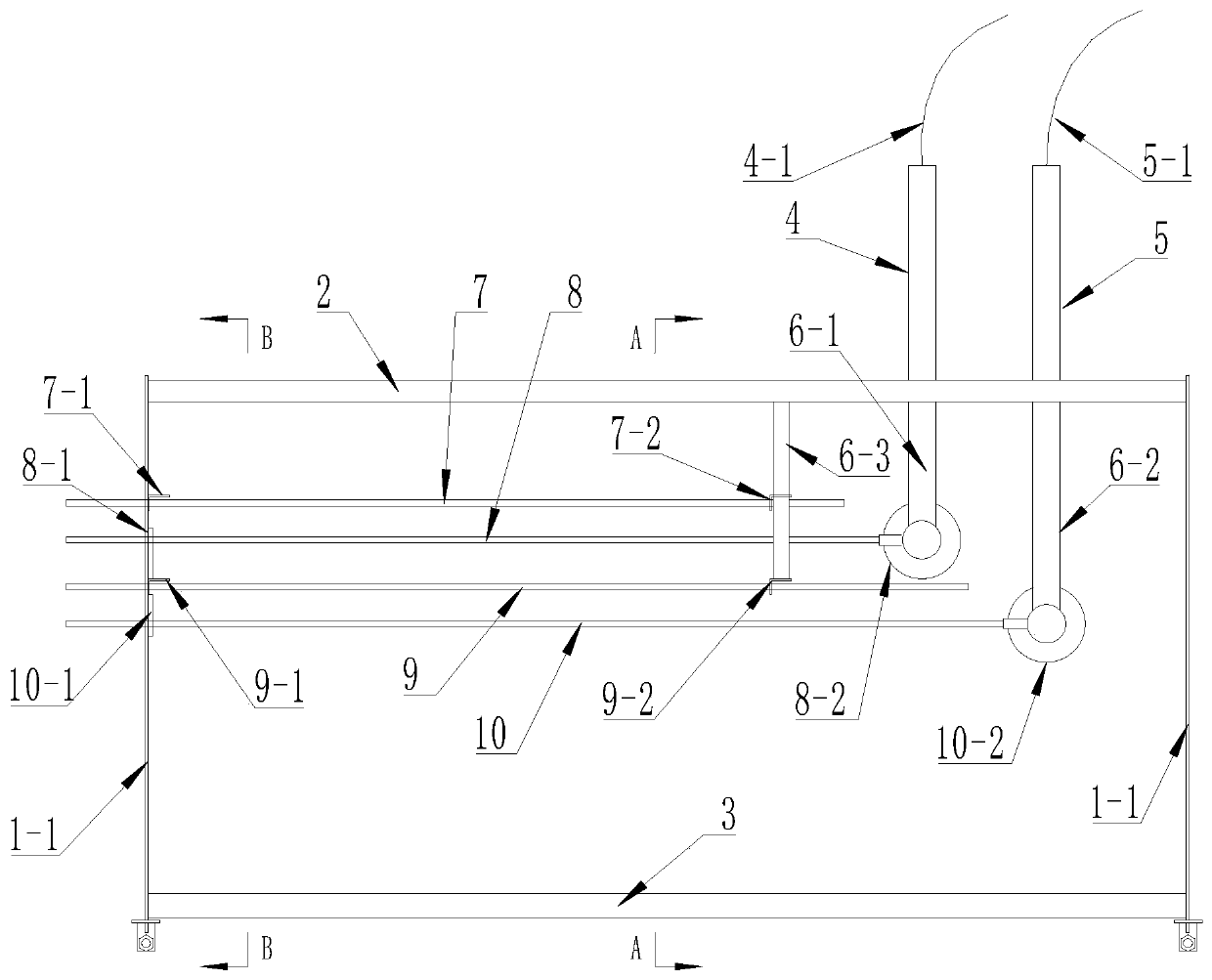

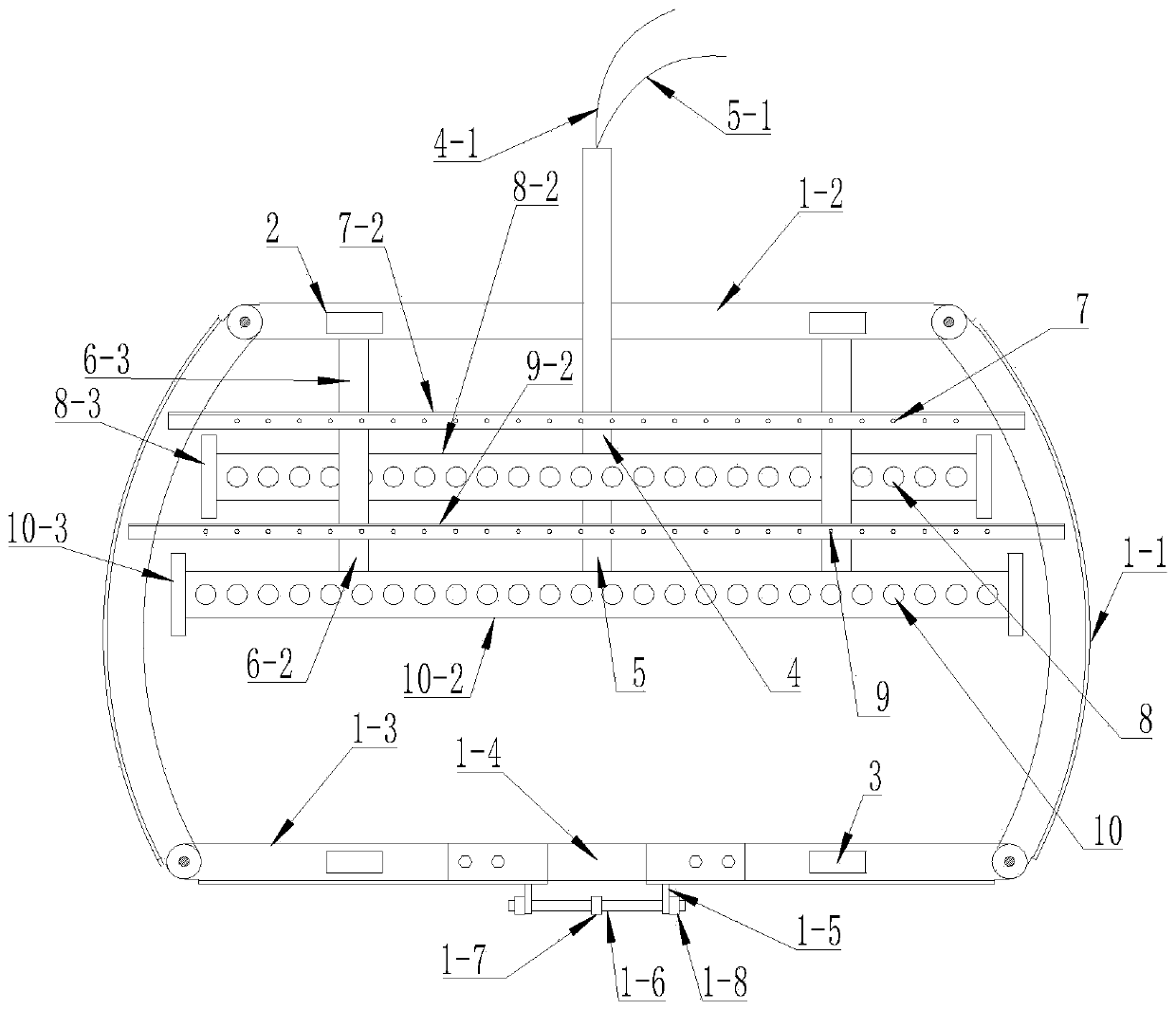

[0048] The structure of the jacking mechanism is as follows: a lifting lug 1-5 is set below the end of the lower horizontal plate 1-3 near the gap, a screw 1-6 is set between the threaded holes of a pair of lifting lugs 1-5, and the screw 1-6 Adjusting nut 1-7 is set in the middle of -6, and the two sides of adjusting nut 1-7 on screw 1-6 are set with external threads in opposite directions, and the two ends of screw 1-6 correspond to the threaded holes of a pair of lifting lugs 1-5 For screw connection, lock nuts 1-8 are arranged at both ends of the screw rod 1-6 through a pair of lifting lugs 1-5.

Embodiment 3

[0050] A protective fixing sleeve 1-4 is arranged between the opposite ends of the pair of lower horizontal plates 1-3 through screws, the lower end of the protective fixing sleeve 1-4 is open, and the section of the protective fixing sleeve 1-4 is C-shaped. The C-shaped opening faces downward.

[0051] The AC 380v50Hz power supply of the network first passes through the circuit breaker and the thyristor rectifier MTC. The functions include rectification and voltage regulation, and then enters the frequency conversion converter in the pulse transformer. The electric field in the desalination tank, there is a detection circuit in the transformer, which continuously monitors the secondary voltage and electric field voltage output by the pulse transformer, and the output secondary current and electric field current, and the detected signal is sent to the microcomputer controller CPU and EM In the module, on the one hand, after being processed, it is sent to the operator in the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com